All-metal multidirectional vibration isolator

A vibration isolator, all-metal technology, applied in the field of all-metal multi-directional integral vibration isolators, can solve problems such as low natural frequency, and achieve the effects of high working reliability, high reliability, and stable overall vibration isolation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

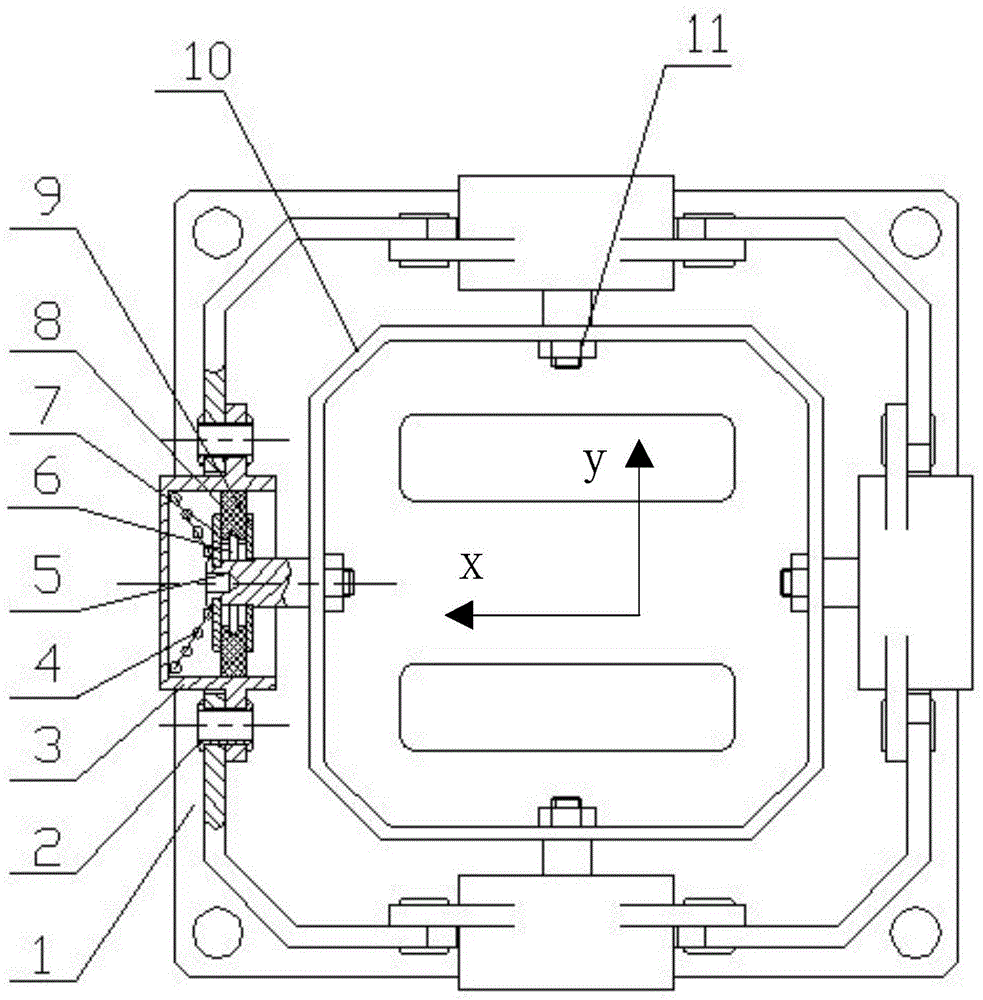

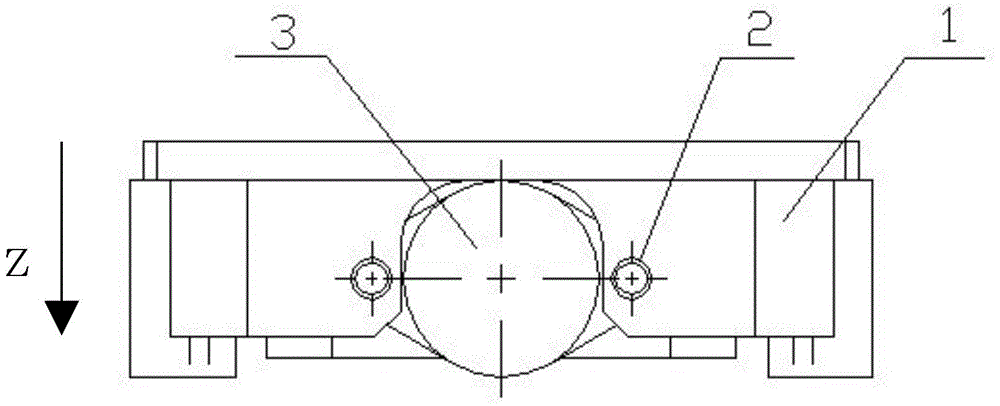

[0015] refer to figure 1 figure 2 . In the embodiment described below, the all-metal multi-directional vibration isolator includes: a boss bracket protruding around the hollow edge plane, a vibration-damping connection box placed in the hollow frame of the boss bracket and fixedly connected to the boss bracket. Describe the elastic vibration isolation unit on the boss bracket 1, wherein: the elastic vibration isolation unit is arranged in the damping cylinder 3, and the damping slider 8 axially connected to the conical spring 4 is composed of bolts passing through the damping cylinder splint in the axial direction. The bolt 5 is fixedly connected on the side plane of the vibration-damping connection box 10 through the top opening of the conical spring 4, the spring collar 6 and the splint; the elastic vibration-isolating unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com