Method for producing manganese dioxide coating carbon nano-tube core-shell type composite material

A technology of nanotube composite and manganese dioxide, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of poor electrical conductivity, achieve the effects of reducing damage, increasing specific surface area, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

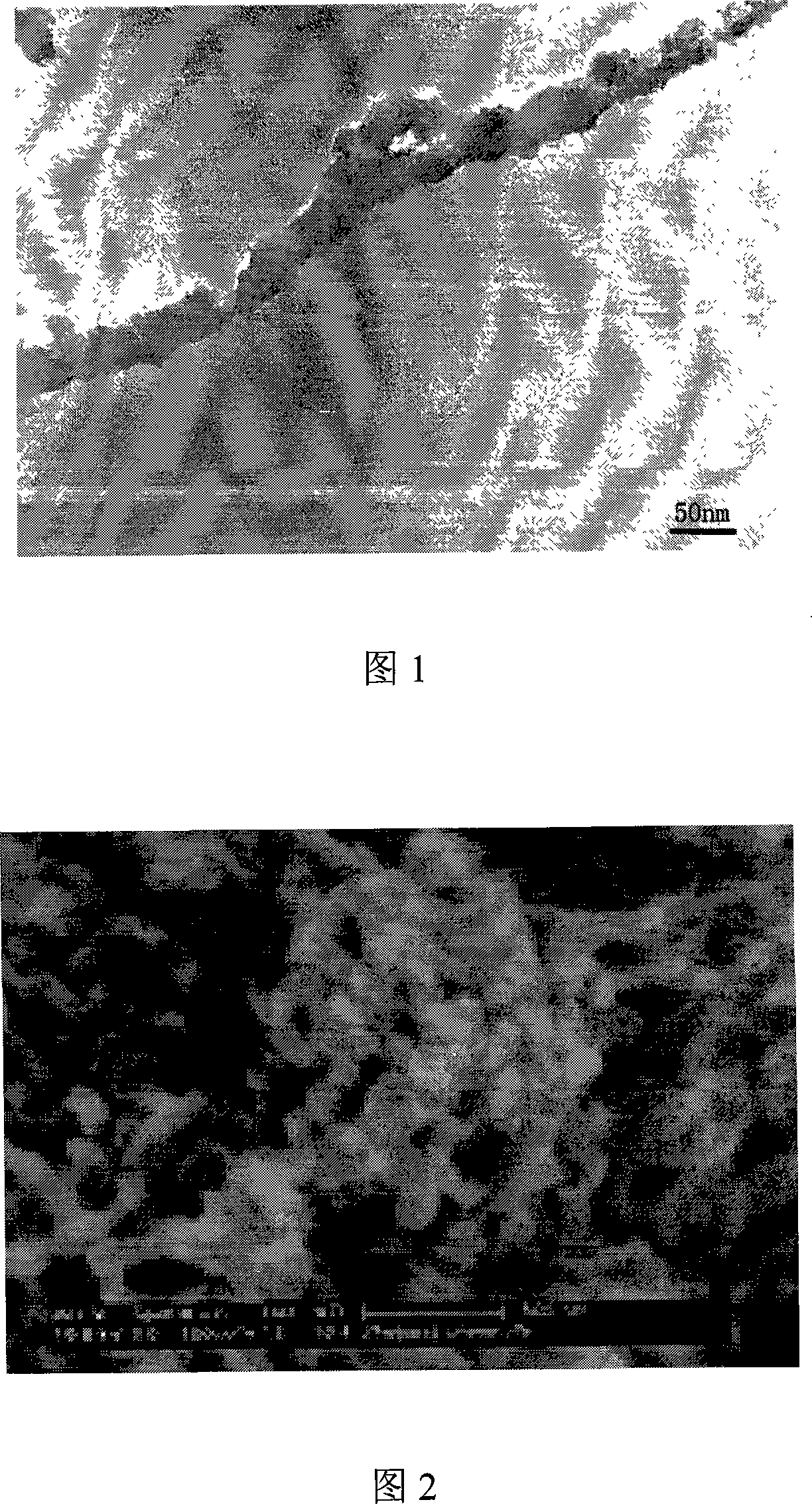

Image

Examples

Embodiment 1

[0019] The carbon nanotubes with a tube diameter of 40nm are added to the mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:1, the amount of the mixed acid is 10 times the mass of the carbon nanotubes, ultrasonically treated for 0.5 hours, filtered, and Repeated washing with distilled water until the pH value of the filtered lotion is 6-7;

[0020] Take 100 mg of carbon nanotubes and 150 mg of sodium dodecylbenzene sulfonate obtained above and add them to 50 ml of water, and after a little stirring, ultrasonic treatment for 0.5 hours, so that the carbon nanotubes are evenly dispersed in water to form a stable suspension;

[0021] Add 1.5g of potassium permanganate and 3ml of 98% concentrated sulfuric acid to the above suspension, stir for a while and then sonicate for 0.5 hours;

[0022] After filtering and dehydrating, wash repeatedly with distilled water until the pH value of the filtered lotion is about 6-7;

[0023] The ...

Embodiment 2

[0026] Carbon nanotubes with a tube diameter of 20nm are added to the mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:1, the amount of mixed acid is 15 times the mass of the carbon nanotubes, ultrasonically treated for 1 hour, filtered, and Repeated washing with distilled water until the pH value of the filtered lotion is 6-7;

[0027] Take 100mg of carbon nanotubes and 200mg of sodium deoxycholate obtained above and add them to 50ml of water, stir them and then ultrasonicate for 1 hour, so that the carbon nanotubes are evenly dispersed in water to form a stable suspension;

[0028] Add 2.0g of potassium permanganate and 2ml of 98% concentrated sulfuric acid to the above suspension, stir for a while and then sonicate for 1 hour;

[0029] After filtering and dehydrating, wash repeatedly with distilled water until the pH value of the filtered lotion is about 6-7;

[0030] The resultant is air-dried to obtain the manganese di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com