High-performance hydraulic structure concrete and method for producing the same

A hydraulic structure and concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the volume stability of dam concrete cracking, and the crack resistance of dam concrete is difficult to have a major breakthrough and other problems, to achieve the effect of suitable strength and strength development, high workability and high crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

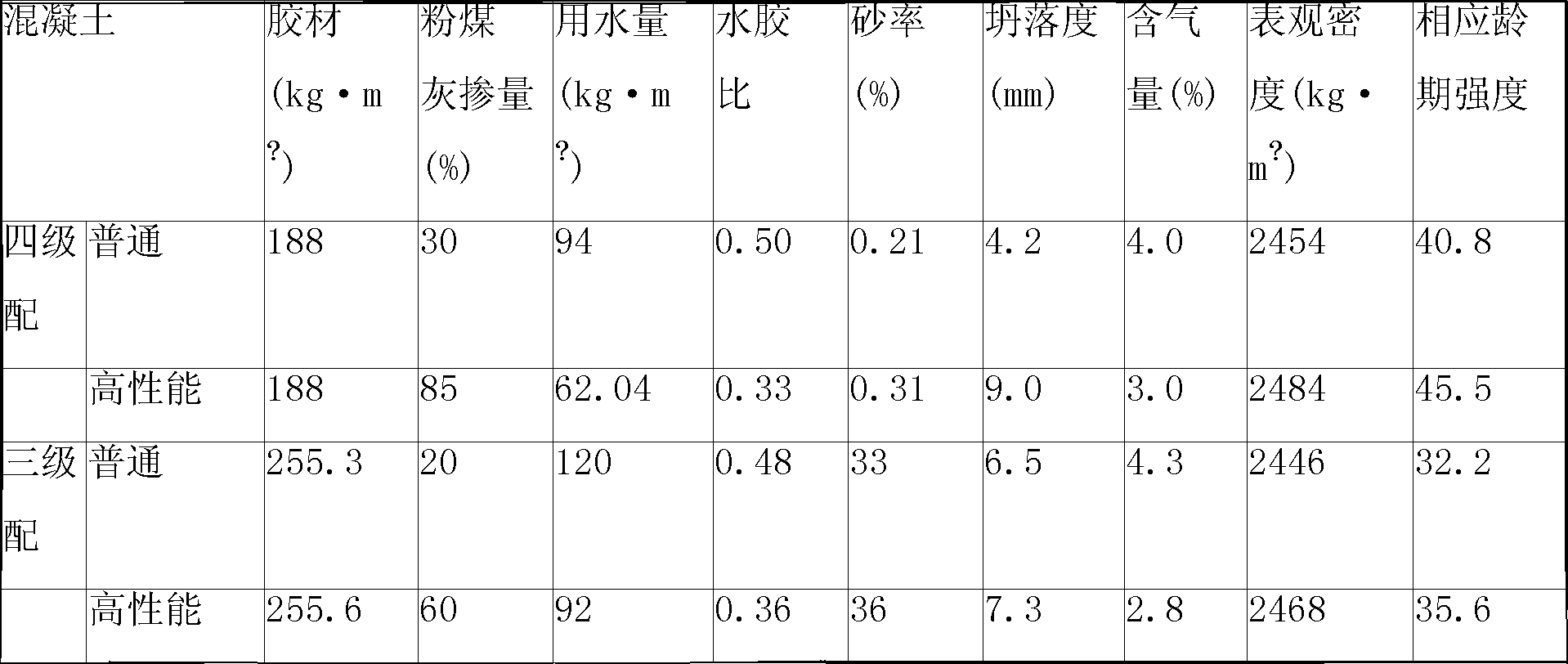

[0028] Raw materials: cement with strength not less than 42.5MPa, national standard II grade fly ash, natural sand or artificial sand with fineness in the range of medium sand, stone with particle size in the range of 5 to 150 mm, polycarboxylic acid series high-performance water reducing The agent and water are measured separately according to the mixing ratio in the table below.

[0029]

[0030] Preparation method: first put the stones into the mixer, then put the cement and the national standard II grade fly ash into the mixer, then put the sand into the mixer, and finally add the polycarboxylic acid-based high-performance water reducing agent and water into the forced concrete mixer and mix 120 Seconds, the apparent density is 2500kg / m 3 One cubic meter of high-performance hydraulic structural concrete. The fourth grade is C30 concrete with an age of 90 days, the third grade is C25 concrete with an age of 28 days, and the second grade is C25 concrete with an age of 28 days....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com