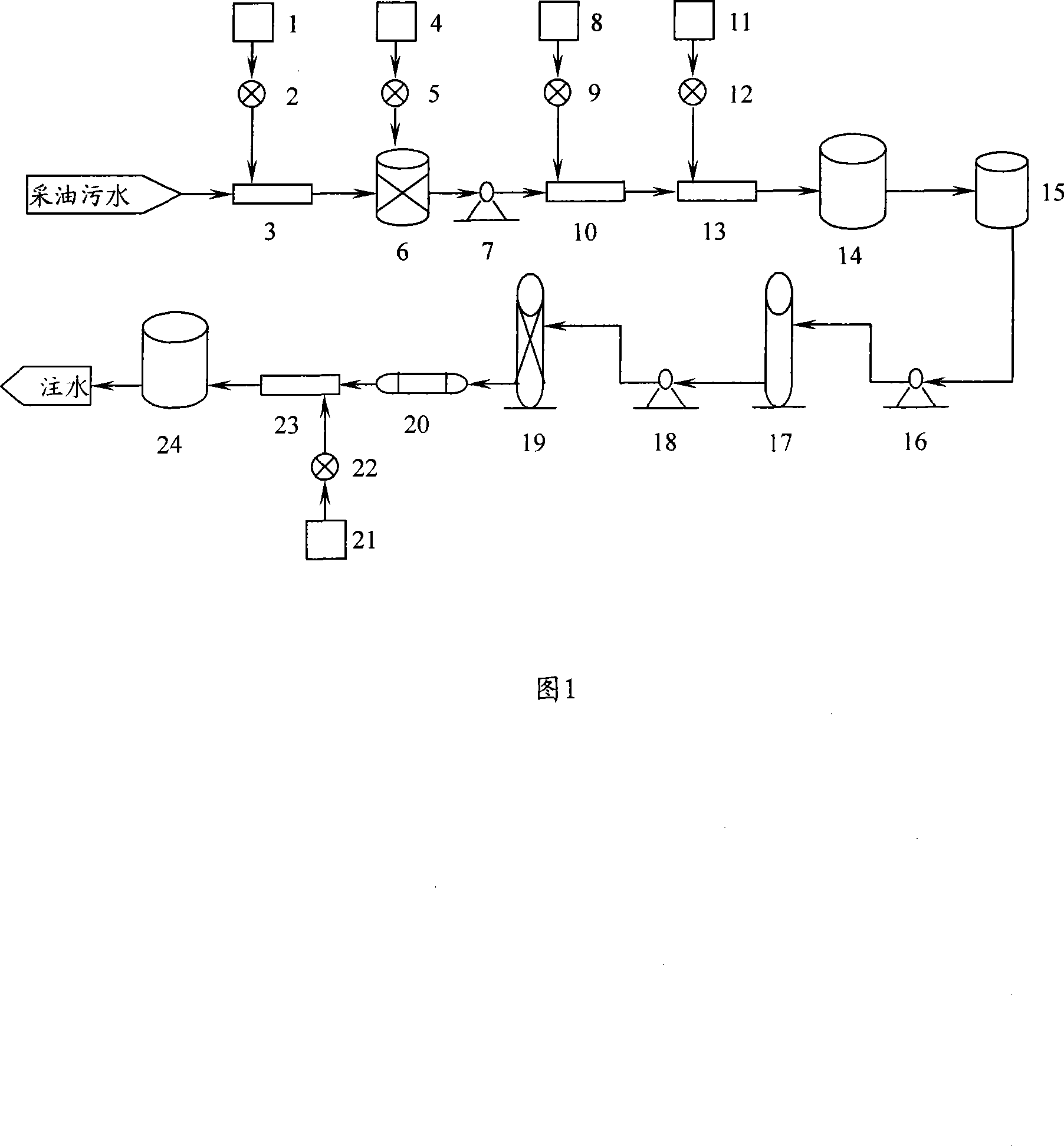

Method and technological process for treating sewage of oil recovery

A technology of oil production sewage and treatment method, which is applied in the field of petroleum sewage treatment, can solve problems such as corrosion and scaling, affect oil recovery rate, etc., and achieve the effect of solving corrosion and scaling and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Treatment of oil production wastewater with high sulfur content and high bacterial content

[0027] 1. Before the oil extraction wastewater from crude oil enters the sulfur removal flocculation reactor, the oxidant hydrogen peroxide 440-460 mg / L is first added through the pipeline mixer to partially oxidize the sulfide in the sewage, and then zinc is added into the reaction tank through the pipeline mixer Salt such as zinc sulfate 60mg / L, to precipitate and remove the remaining divalent sulfur in the sewage.

[0028] 2. Add 8 million units of polyacrylamide 1.0 mg / L flocculant to the oil production sewage after desulfurization treatment through the pipeline mixer to flocculate the sediment, oil and other substances in the sewage.

[0029] 3. After the flocculation treatment, the oil production sewage is sterilized by adding 60mg / L fungicide glutaraldehyde or isothiazolinone through the pipeline mixer, and at the same time, it is settled and separated in the s...

example 2

[0037] Example 2 provides a treatment method for low-turbidity sulfur-containing oil production wastewater.

[0038] 1. Before the oil production sewage from crude oil enters the sulfur removal flocculation reactor, first add oxidant sodium hypochlorite 30-40 mg / L through the pipeline mixer to partially oxidize the sulfide in the sewage, and then add zinc into the reaction tank through the pipeline mixer Salt such as zinc sulfate heptahydrate 50mg / L, or add iron salts, such as ferric sulfate, ferric chloride, polyferric sulfate 50mg / L, to precipitate and remove the remaining divalent sulfur in the sewage.

[0039] 2. Add 8 million units of polyacrylamide 1.0 mg / L flocculant to the oil production sewage after desulfurization treatment through the pipeline mixer to flocculate the sediment, oil and other substances in the sewage.

[0040] 3. After the flocculation treatment, the oil production sewage is sterilized by adding 50 mg / L bactericide dodecyldimethylbenzyl ammonium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com