Closed type fluid machine

A technology of fluid machinery and fluid pressure, applied in the field of closed fluid machinery, can solve the problems of fluid machinery productivity decline, device enlargement, cost increase, etc., achieve the effect of suppressing weight increase, preventing enlargement, and ensuring quietness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

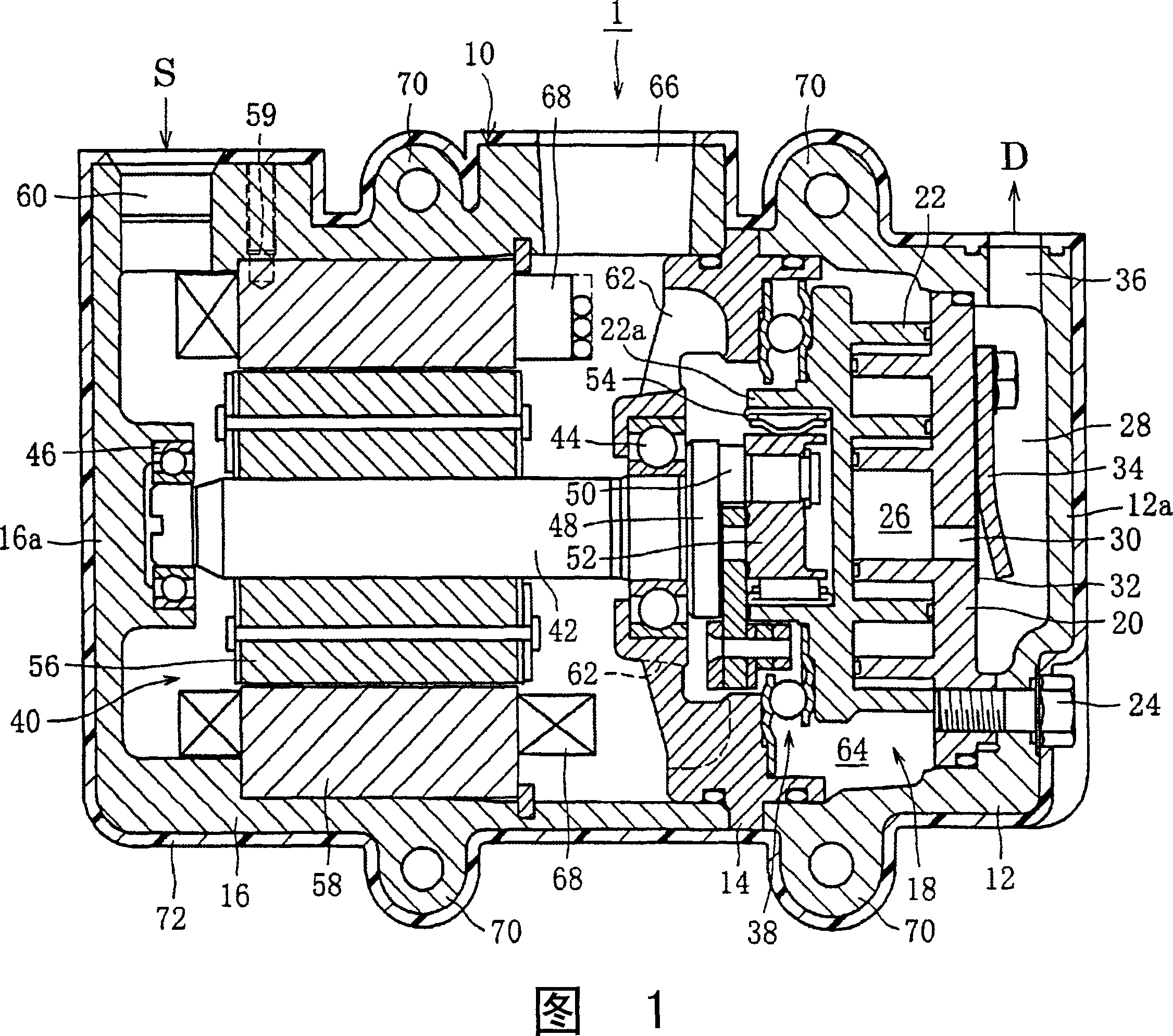

[0024] FIG. 1 shows an electric scroll compressor 1 as a hermetic fluid machine according to an embodiment of the present invention. This compressor 1 is used, for example, as a compressor for a refrigeration circuit of a refrigerator. The compressor 1 has a cylindrical housing 10 including a unit housing 12 , a support arm 14 , and a stator housing 16 in this order from the right in FIG. 1 . Both the unit case 12 and the stator case 16 are formed of aluminum, and are joined to each other with the support arm 14 interposed therebetween. The casings 12, 16 and the support arm 14 are hermetically bonded by O-rings, respectively.

[0025] A scroll unit 18 serving as a fluid pressure unit is accommodated in the unit case 12 . The scroll unit 18 has a fixed scroll 20 and a movable scroll 22 . The movable scroll 22 is arranged on the support arm 14 side, and the fixed scroll 20 is fixed to the end wall 12 a of the unit casing 12 by a plurality of fixing bolts 24 . These scroll wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com