Fluorescent composite glass, fluorescent composite glass green sheet and process for production of fluorescent composite glass

A composite glass and manufacturing method technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of deterioration, poor weather resistance, and inability to make thickness, etc., and achieve the effect of reducing shrinkage and deformation, thin thickness, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Hereinafter, the present invention will be described in detail based on examples.

[0072] First, a phosphor composite glass green sheet was produced as follows.

[0073] In terms of composition, it is calculated by mass percentage, containing SiO 2 50%, B 2 o 3 5%, CaO 10%, BaO 25%, Al 2 o 3 5%, ZnO 5% composition method, mixed glass raw materials of various oxides. After being uniformly mixed, the mixture was charged into a platinum crucible and melted at 1400° C. for 2 hours to produce a uniform glass. The resulting glass was pulverized with alumina balls and classified to obtain a glass powder having an average particle diameter of 2.5 µm. Next, to the prepared glass powder, an inorganic phosphor powder (average particle size of YAG phosphor powder manufactured by Kasei Obutonics Co., Ltd.: 8 μm) was added and mixed at a mass ratio of 95:5 to obtain a mixed powder. . Next, 30% by mass of methacrylic resin as a binder, 3% by mass of dibutyl phthalate as a p...

Embodiment 2

[0079] First, the phosphor composite glass green sheet produced in Example 1, and a porous ceramic mullite substrate as a constraining member were prepared.

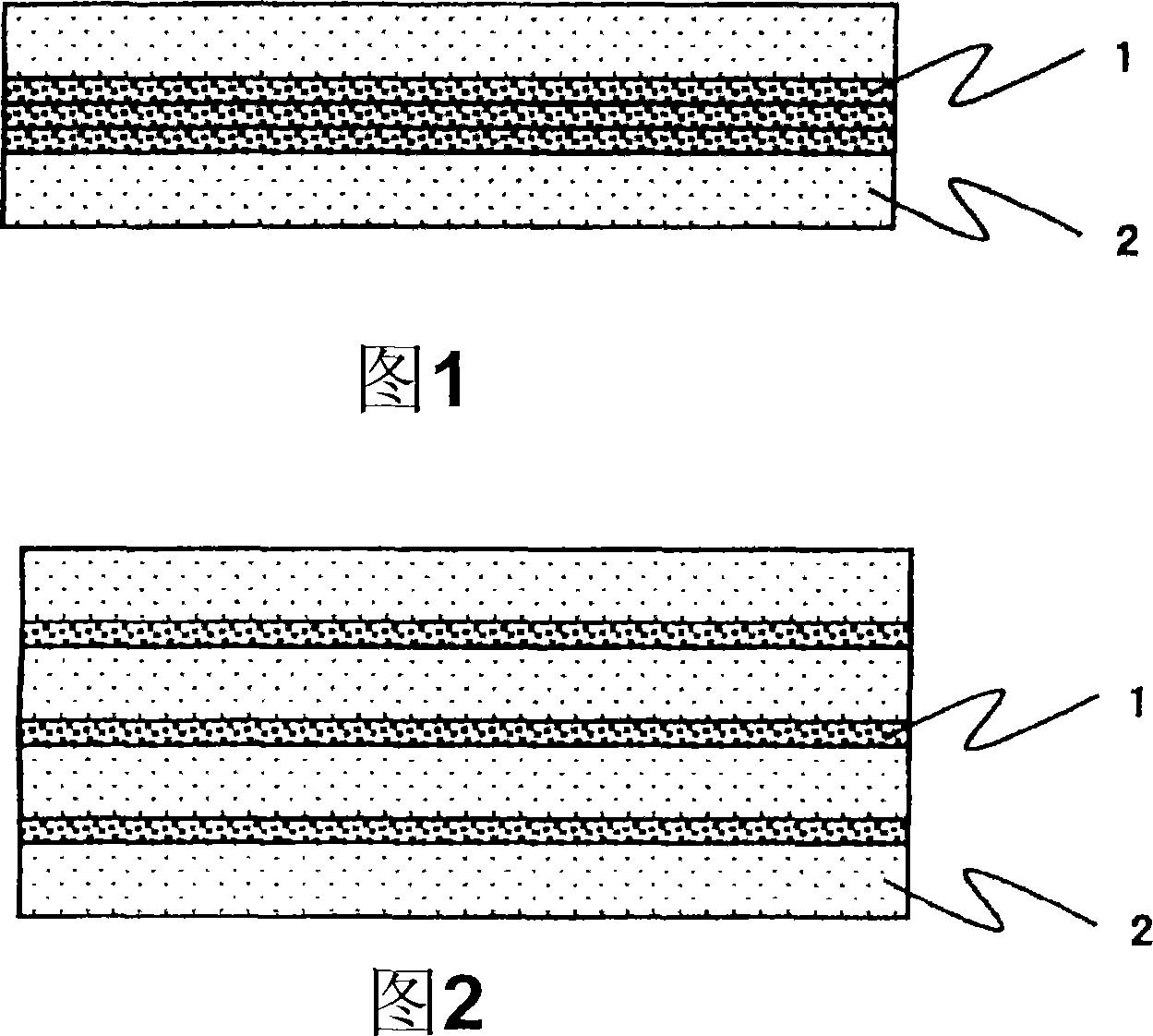

[0080] Next, cut the mullite substrate and phosphor composite glass green sheet into a size of 100×100 mm. As shown in FIG. 2 , four mullite substrates and three phosphor composite glass green sheets were stacked on top of each other, and bonded by thermocompression to form an integrated body to produce a laminate. Then, it was fired at 900°C. Thereafter, the mullite substrate was removed, and three phosphor composite glasses with a size of 100×100 mm and a thickness of 40 μm were produced.

[0081] The thus-produced phosphor composite glass was irradiated with blue light from the back of the phosphor glass to obtain white transmitted light. Furthermore, the energy conversion efficiency and porosity were also measured, and the energy conversion efficiency was 13%, and the porosity was 2%.

Embodiment 3

[0083] Contains ZnO 35%, B in terms of mass percentage 2 o 3 40%, SiO 2 10%, Na 2 O 10%, Al 2 o 3 5% of the composition of the glass raw materials to reconcile various oxides. After being uniformly mixed, it was placed in a platinum crucible and melted at 1100° C. for 2 hours to obtain a uniform glass. The obtained glass was pulverized with alumina balls and classified to obtain glass powder with an average particle diameter of 2.5 μm. Next, to the obtained glass powder, an inorganic phosphor powder (average particle size of YAG phosphor powder manufactured by Kasei Obtonix Co., Ltd.: 8 μm) was added and mixed at a mass ratio of 95:5 to prepare a mixed powder. Next, 30% by mass of methacrylic resin as a binder, 3% by mass of dibutyl phthalate as a plasticizer, and 20% by mass of toluene as a solvent were added to the obtained mixed powder 100, and mixed , making slurry. Next, a sheet was formed on the PET film by the doctor blade method, and dried to produce a phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com