Powder material automatic rationing fluidity test device and method

A technology of testing device and testing method, applied in the direction of flow characteristics, measuring device, analyzing material, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

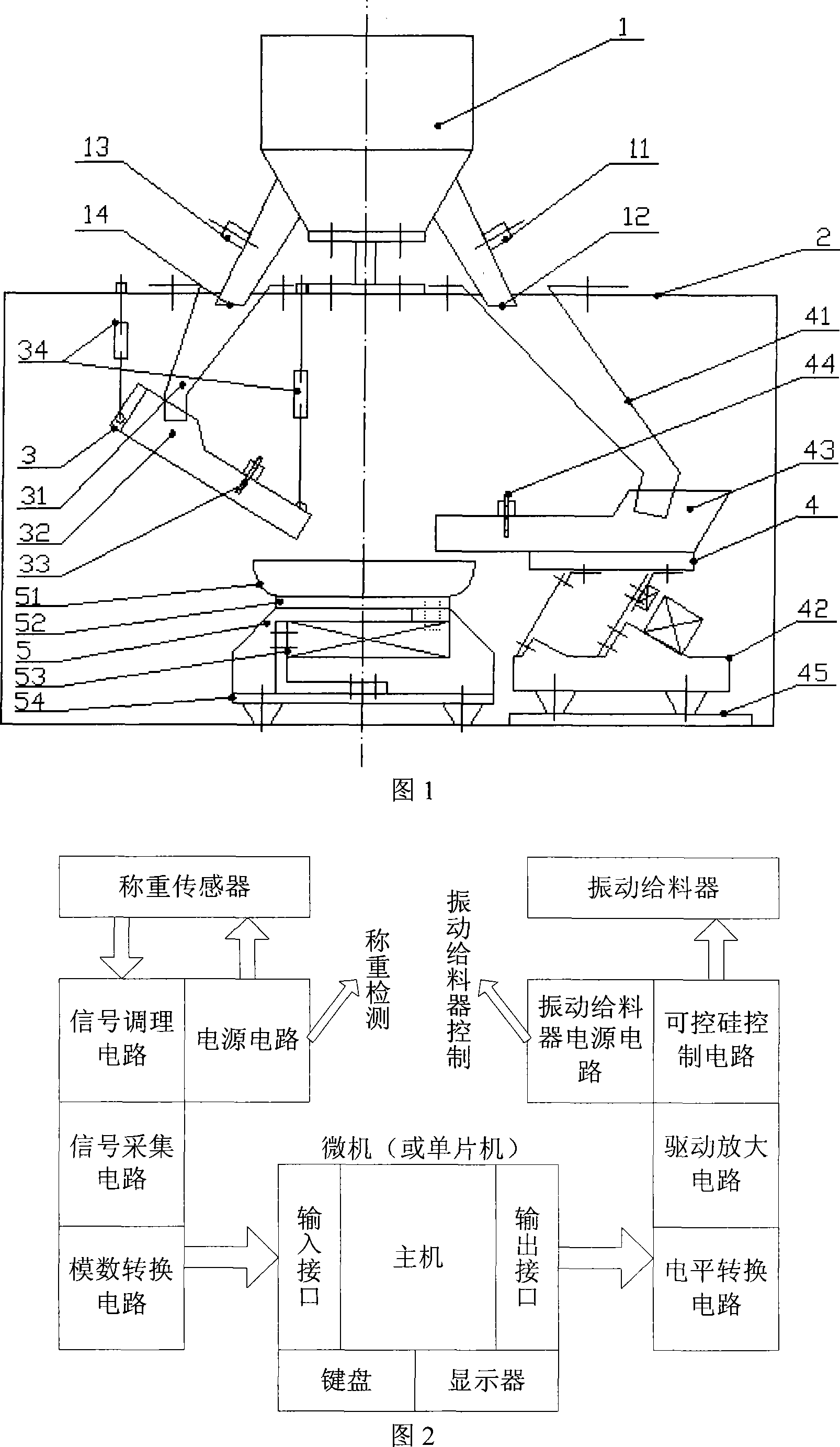

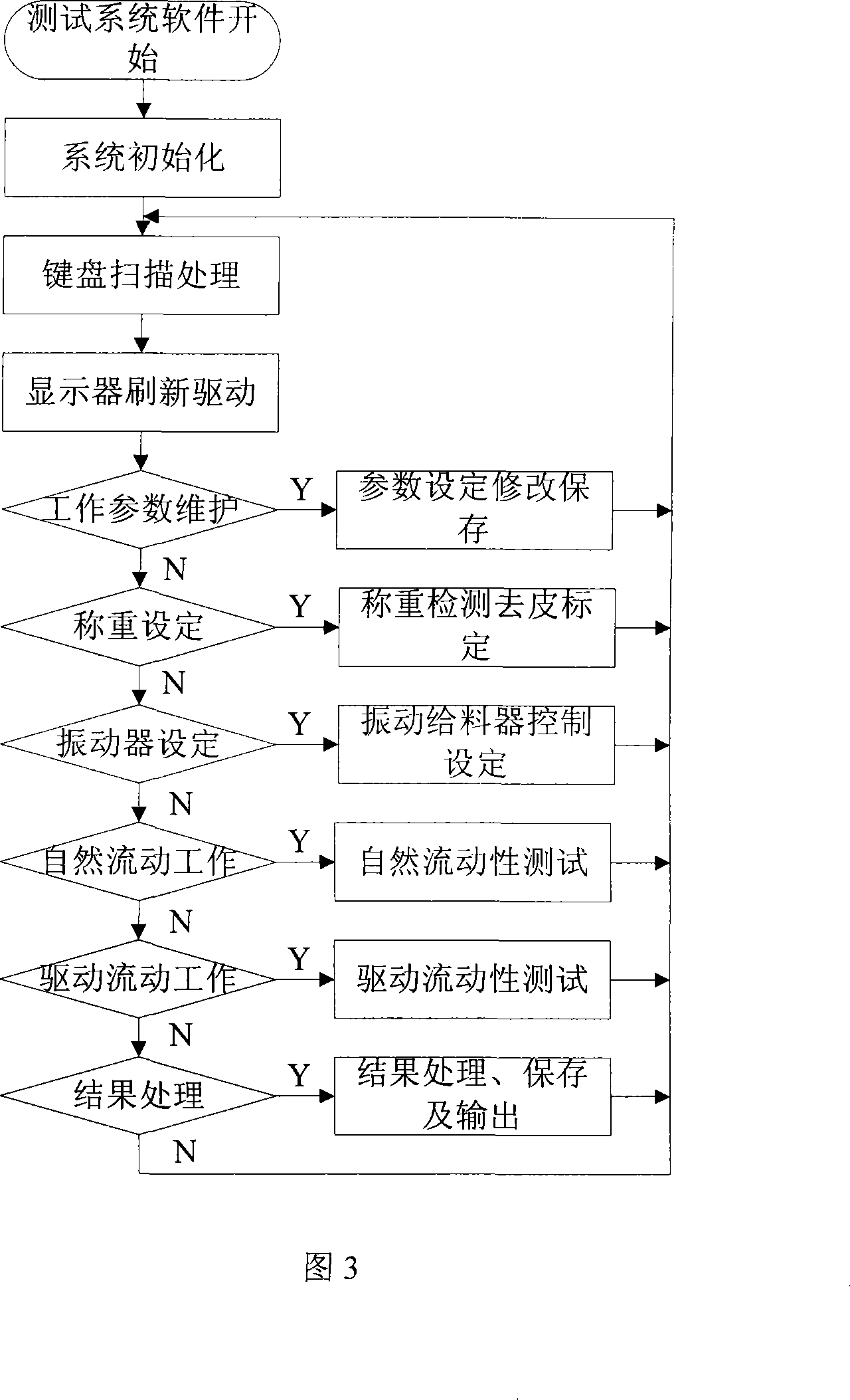

[0019] As shown in Figure 1, the automatic quantitative fluidity testing device for powdery material according to the present invention consists of three parts: mechanical part, microcomputer testing hardware and software, wherein the mechanical part includes silo 1, frame 2, gravity conveying part 3. Vibrating conveying part 4 and weighing platform 5 are five parts. The left and right lower parts of the bin 1 are respectively equipped with a left discharge port 14, a left discharge control valve 13, a right discharge port 12, and a right discharge control valve 11; The conveying part 3 includes an artesian material guide pipe 31 and an artesian conveying trough 32 which are sequentially communicated with the left discharge port 14. The artesian material thickness regulator 33 arranged on the artesian conveying trough 32 and the artesian conveying trough 32 are suspended on the Top left inside rack 2. The vibrating delivery part 4 comprises a vibrating feeder 41 communicated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com