Temperature measuring circuit

A temperature measurement circuit and circuit technology, applied in thermometers, measuring devices, measuring heat, etc., can solve problems such as inability to eliminate the influence of wire resistance, single test object, and data jumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

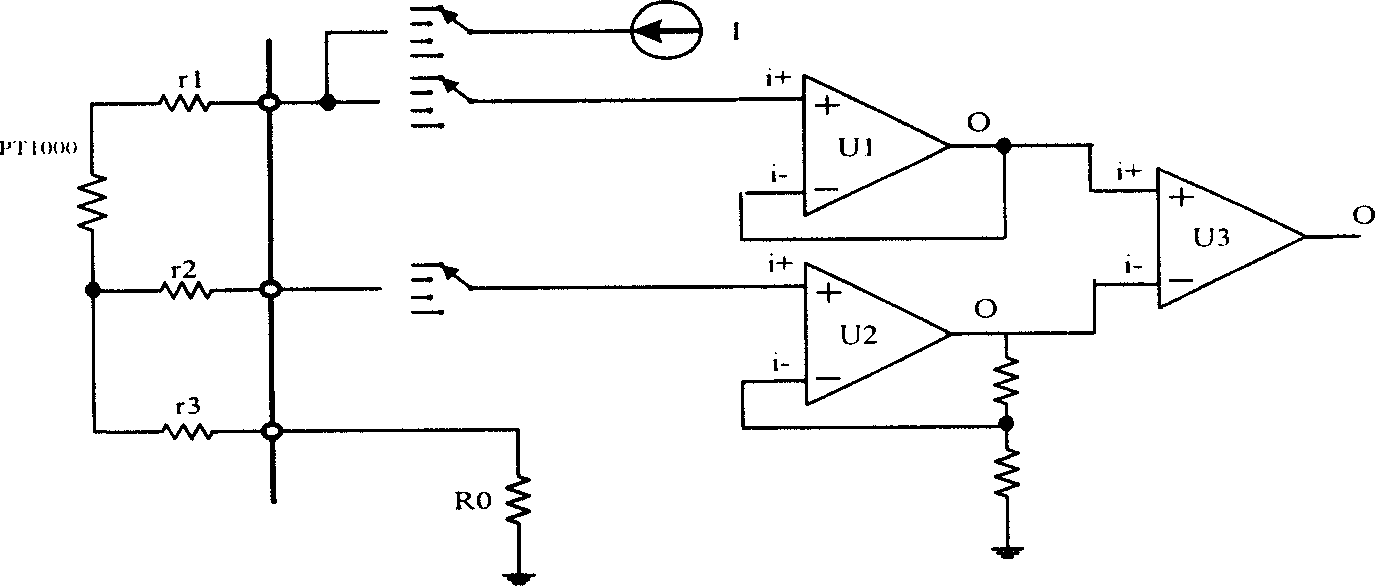

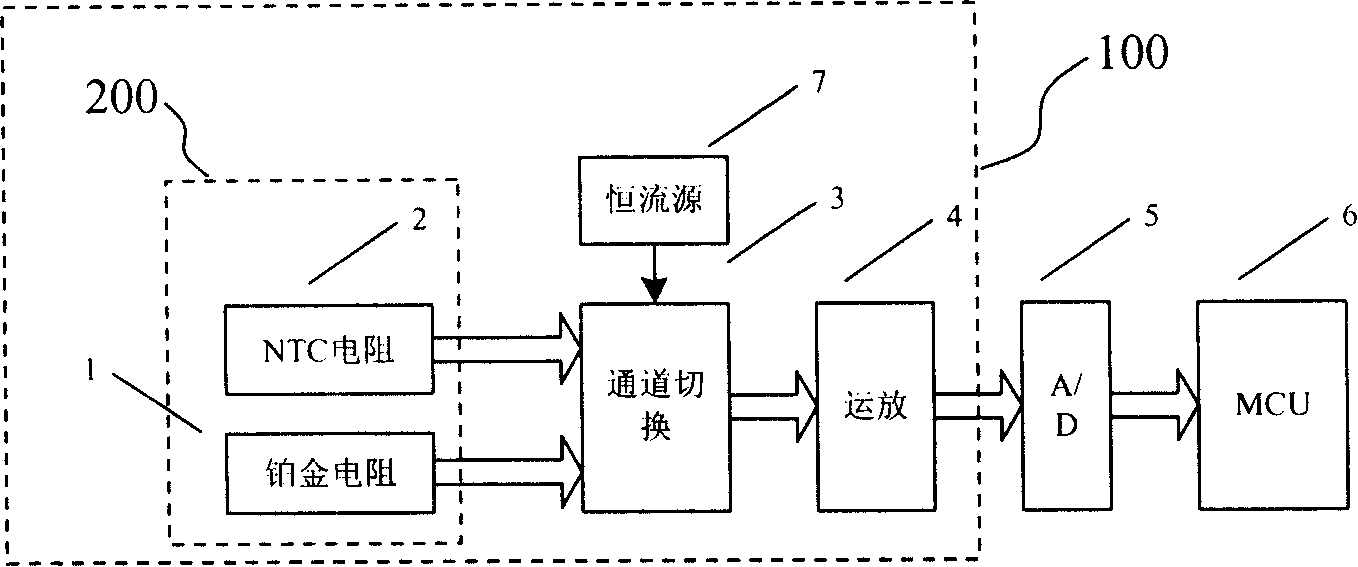

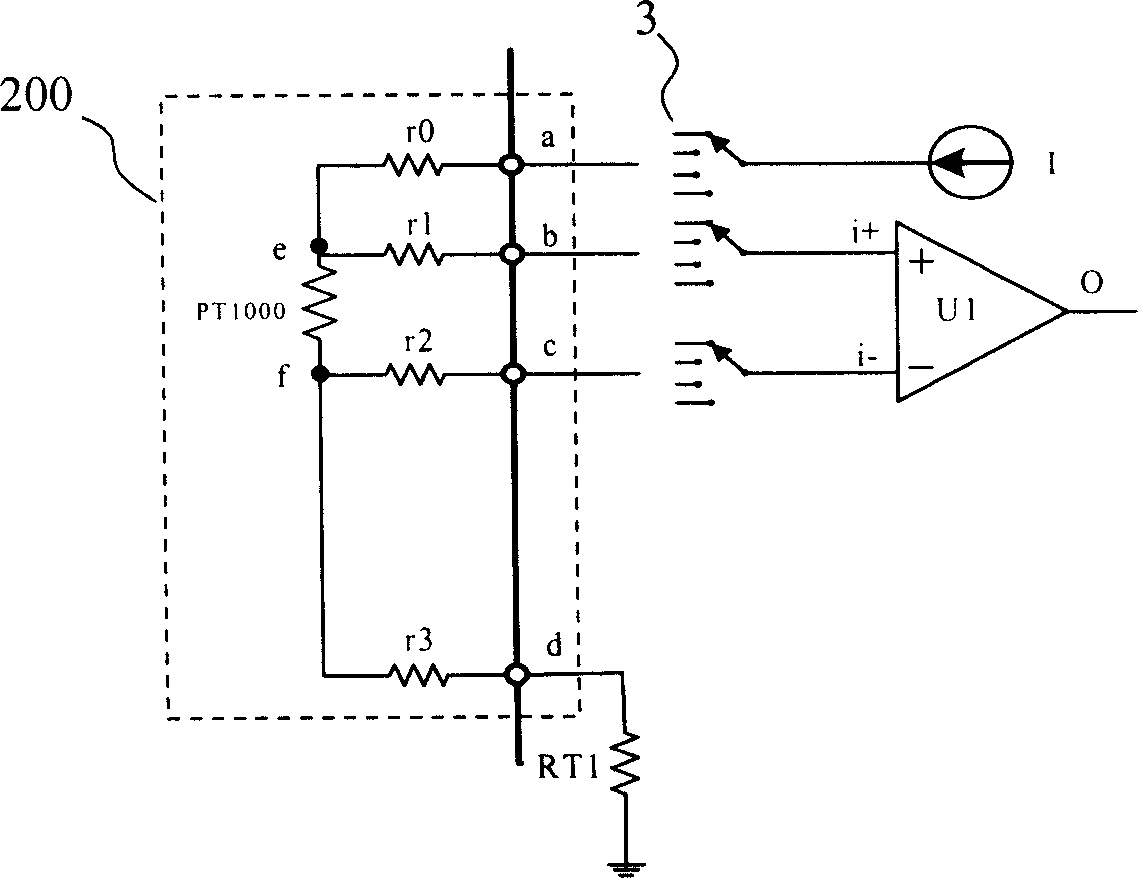

[0038] The block diagram of the temperature measurement circuit of the preferred embodiment of the present invention is as figure 2 As shown, the temperature measurement circuit 100 includes a temperature sensor circuit 200 , a channel switching device 3 , an operational amplifier 4 and a constant current source 7 . The whole temperature measurement system also includes A / D acquisition circuit 5 and MCU 6 .

[0039] The temperature sensor circuit 200 may include multiple channels, the resistance of the temperature sensor will vary with the temperature, the channel switching device 3 is used to switch between multiple sensor channels, and the current of the constant current source 7 will flow through the switched The sensor converts the resistance of the sensor into a voltage for measurement, and the voltage value will be input to the operational amplifier 4 to realize the amplification processing of the weak voltage signal of the sensor, and the A / D acquisition circuit 5 will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com