Excellent carbon-steel on-line forecasting and tissue sorbitizing controlling method

A technology of controlling structure and sorbite, which is applied in heat treatment process control, manufacturing tools, furnaces, etc., can solve unsatisfactory problems, achieve the effects of reduced quality objection loss, stable mechanical properties, and increased sorbite rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

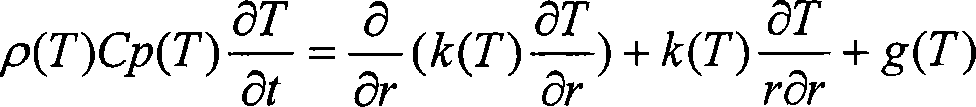

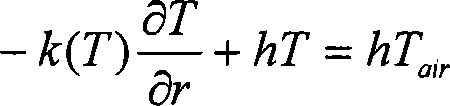

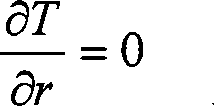

[0043] In order to make the purpose, technical solution and advantages of the present invention clearer, a method for controlling the structure of Soxhlet of high-quality carbon steel according to the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0044] In the existing stelmore controlled cooling process, the stelmore controlled cooling device is used to connect with the main rolling line programmable logic controller (Programmable Logic Controller, PLC) to realize water cooling and air cooling control.

[0045] Describe in detail below the excellent carbon steel material control structure sorbite method of the present invention, comprise the following steps:

[0046] In step S100 , in the air-cooling section of Stelmore controlled cooling, the cooling te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com