Low water content high heating value coal dust and its preparing method and device

A manufacturing method and technology of water content, applied in lighting and heating equipment, heating to dry solid materials, special forms of dry distillation, etc. The effect of less suction, energy saving and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

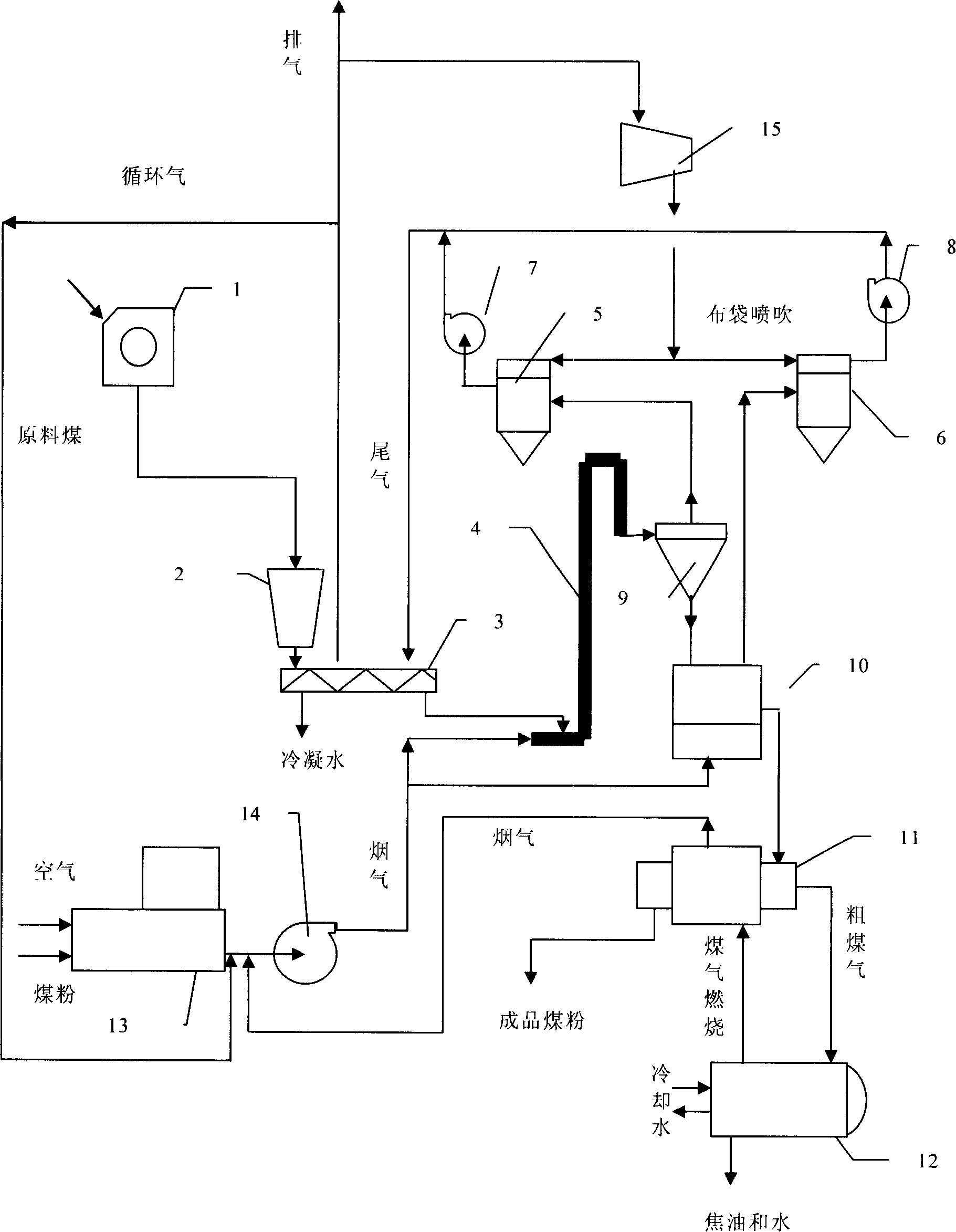

[0051] see figure 1 . Tongliao lignite with a water content of 35-40% is pulverized by a pulverizer 1 and sieved by a vibrating sieve to obtain pulverized coal with a particle size of less than 6 mm, which is sent to a pulverized coal bin 2 for storage.

[0052]The pulverized coal in the pulverized coal bunker 2 is preheated in the preheating coal feeder 3 through the exhaust gas sent from the induced draft fan 7 and the induced draft fan 8, and the waste heat and condensed water in the exhaust gas are recovered. The preheated coal powder enters the airflow dryer 4 for preliminary drying, and the temperature of the drying medium of the airflow dryer is controlled at about 500°C, so that the moisture in the large pores of the coal powder evaporates rapidly within 0.5-2 seconds. After this process, the moisture contained in lignite is reduced from 35-40% to 10-20%. Make the pulverized coal separated and collected by the cyclone separator 9 enter the fluidized bed dryer 11, use...

Embodiment 2

[0056] The pulverized coal dried by the fluidized bed dryer 10 in Example 1 is transported to the thermal reactor 11, and the reactor is capable of continuous feeding and discharging operations. In this reactor, the pulverized coal is heated to 360°C and kept at this temperature for 30 minutes. The crude gas produced in the thermal reactor 11 is sent to the tar condenser 12 to condense and recover the tar therein. The remaining non-condensable gas is sent back to the thermal reactor 11 for combustion by the tar condenser 12, and is used as heating fuel for the thermal reactor. The flue gas produced by combustion is sent back to the blower 14 to be used as a supplement to the drying medium of the airflow dryer 4 and the fluidized bed dryer 10 .

[0057] Cool the thus prepared detarred pulverized coal until its temperature drops below the self-ignition point of the pulverized coal before discharging. The cooling process uses the above-mentioned flue gas as a protective gas to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com