Method for preparing electric polypyrrole nano hollow sphere

A pyrrole nanometer and conductive polymerization technology is applied in the field of preparation of composite nanometer hollow spheres, which can solve the problems of high production cost, different sizes of hollow spheres, and difficulty in industrialization, so as to avoid waste and recycling costs, reduce intermediate processes, and reduce The effect of intermediate steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, the preparation of polypyrrole hollow nanosphere

[0016] Weigh 0.15g of silica nanospheres and add them to 30ml of deionized water, ultrasonically disperse for 15 minutes, then add 0.1ml of pyrrole monomer, close the reaction system, and ultrasonically disperse for 30-45 minutes, so that the pyrrole monomer and silica nanospheres are fully Disperse evenly, transfer the reaction system to a reaction kettle, add ammonium persulfate aqueous solution (0.15g ammonium persulfate dissolved in 7.5ml deionized water), react at 180°C for 4 hours, filter and wash to obtain composite core-shell particles; The composite particle is added into 37% hydrofluoric acid, and after reacting for 12-24 hours, the unreacted hydrofluoric acid is neutralized with sodium hydroxide solution, and the black insoluble matter is filtered, washed with water, and washed with absolute ethanol. Collect the washed black filter cake.

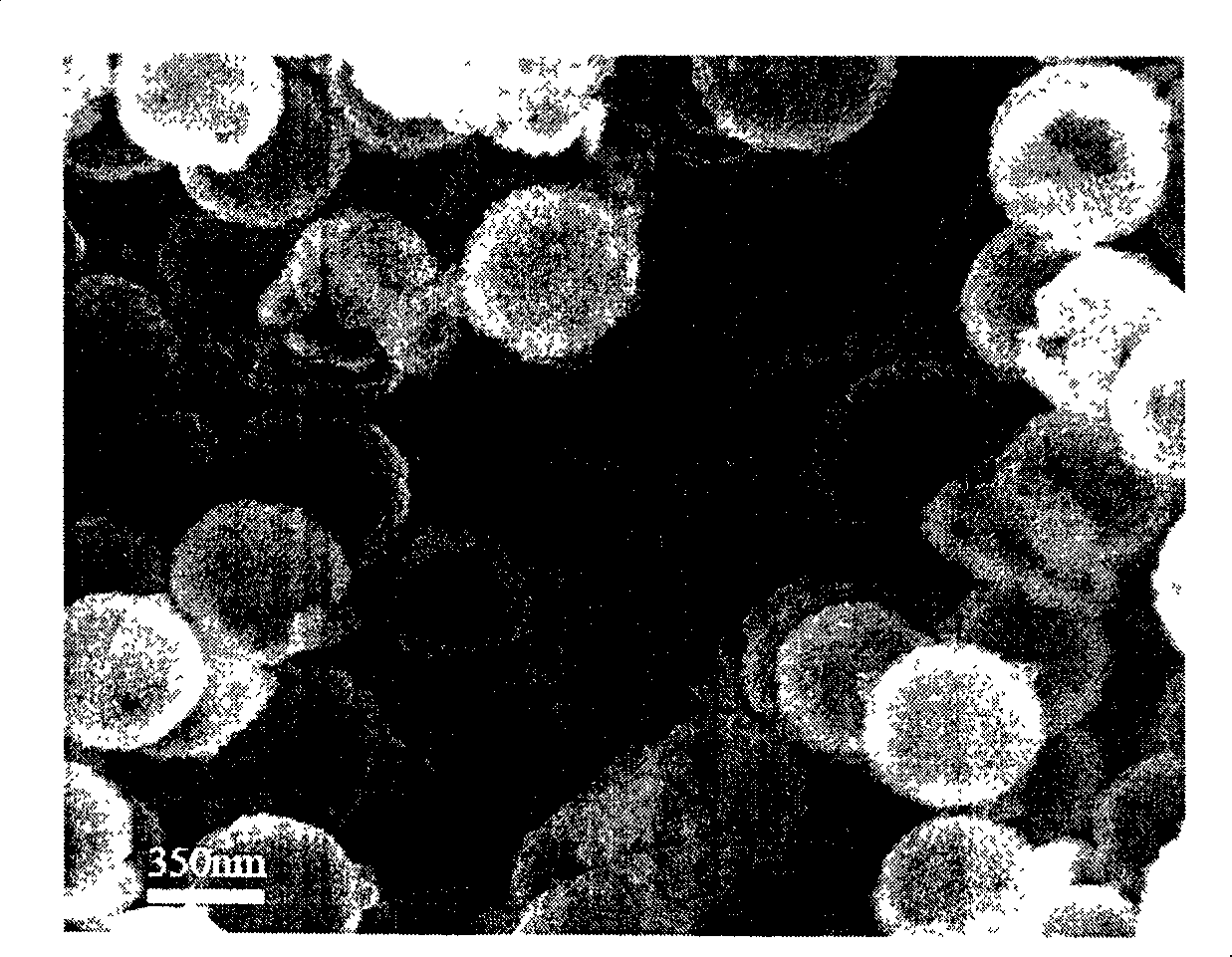

[0017] Synthesized polypyrrole nanohollow spheres such ...

Embodiment 2

[0018] Embodiment 2, preparation of polypyrrole hollow nanospheres

[0019] Weigh 1.5g of silica nanospheres and add them to 30ml of deionized water, ultrasonically disperse for 15 minutes, then add 1ml of pyrrole monomer, close the reaction system, and ultrasonically disperse for 30-45 minutes to fully disperse the pyrrole monomer and silica nanospheres Evenly, transfer the reaction system to the reaction kettle, add ammonium persulfate aqueous solution (0.15g ammonium persulfate dissolved in 7.5ml deionized water), react at 100°C for 8 hours, filter and wash to obtain composite core-shell particles; Add the particles into 37% hydrofluoric acid, react for 12-24 hours, neutralize the unreacted hydrofluoric acid with sodium hydroxide solution, filter the black insoluble matter, wash it with water, and wash it with absolute ethanol. Collect the washed black filter cake.

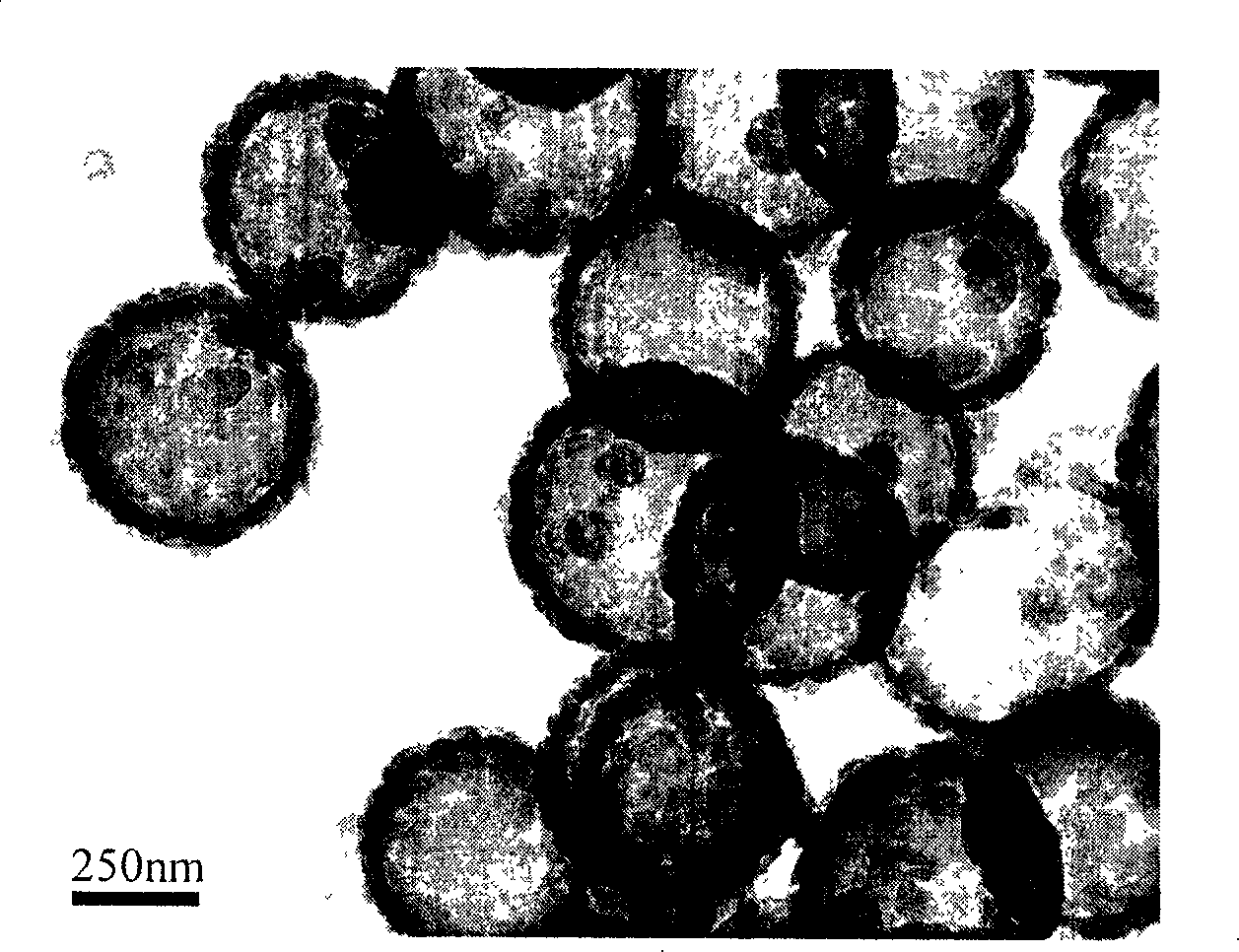

[0020] Synthesized polypyrrole nanohollow spheres such as figure 2 As shown, the diameter of the hollow n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com