Secondary battery

A technology for secondary batteries and battery boxes, which is applied to battery pack components, battery covers/end covers, battery boxes/coatings, etc. It can solve the problems of reduced strength of insulating rings, reduced impact resistance, and dissipation, so as to ensure total Area, breakage prevention, high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

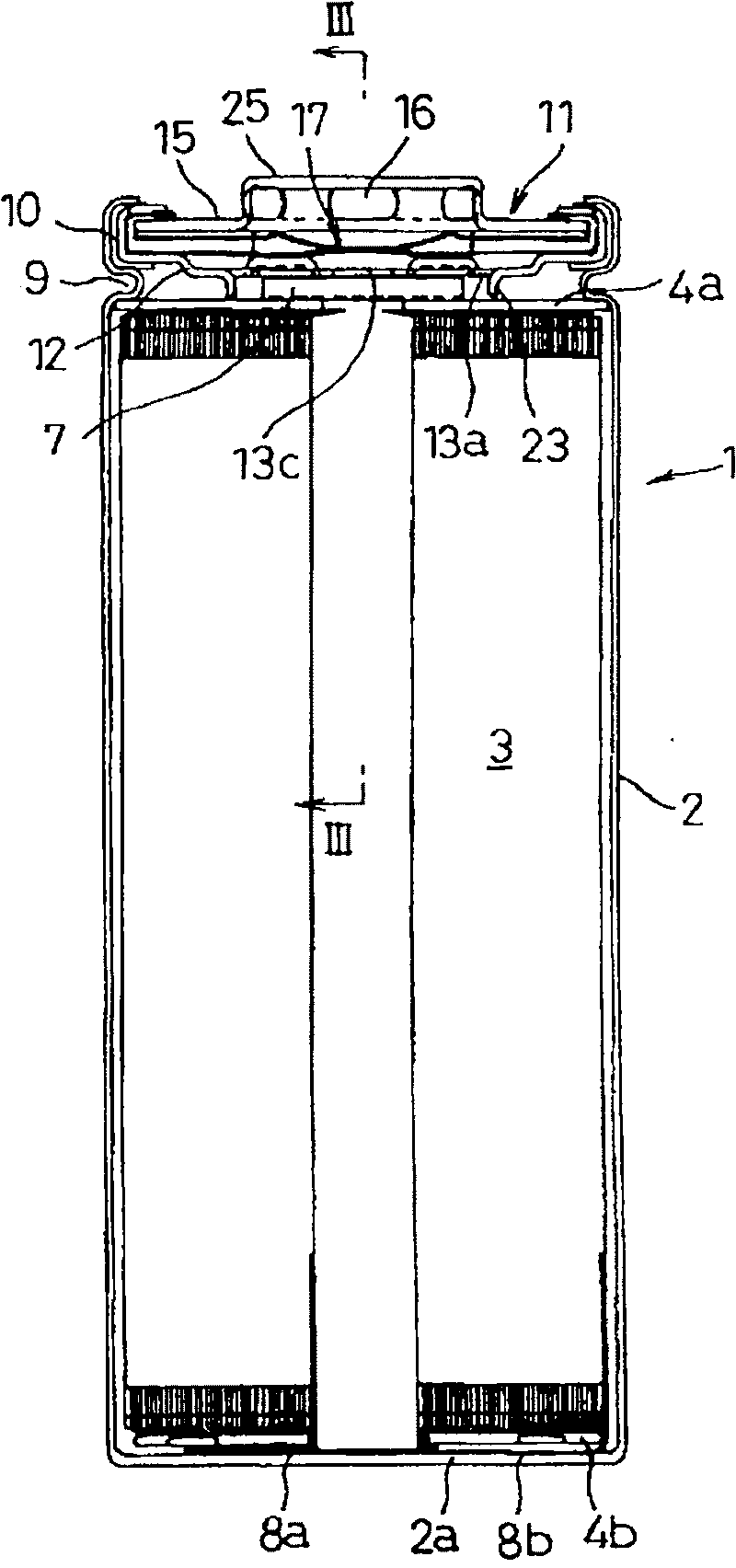

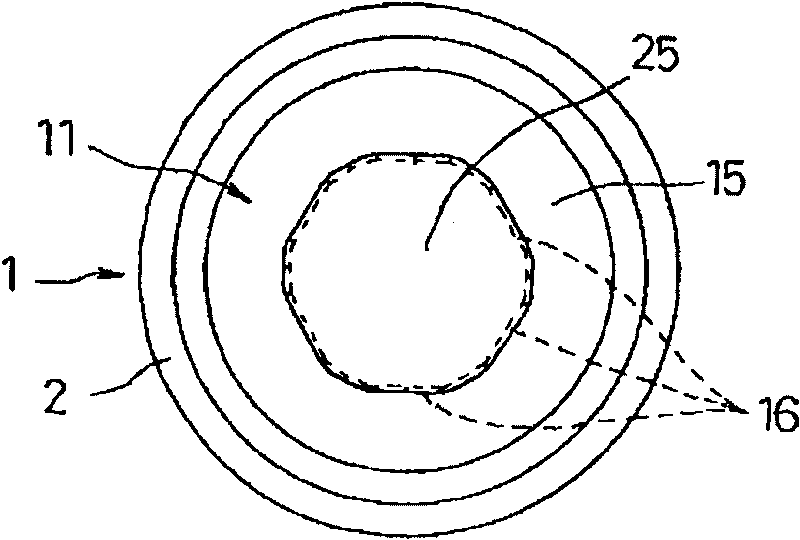

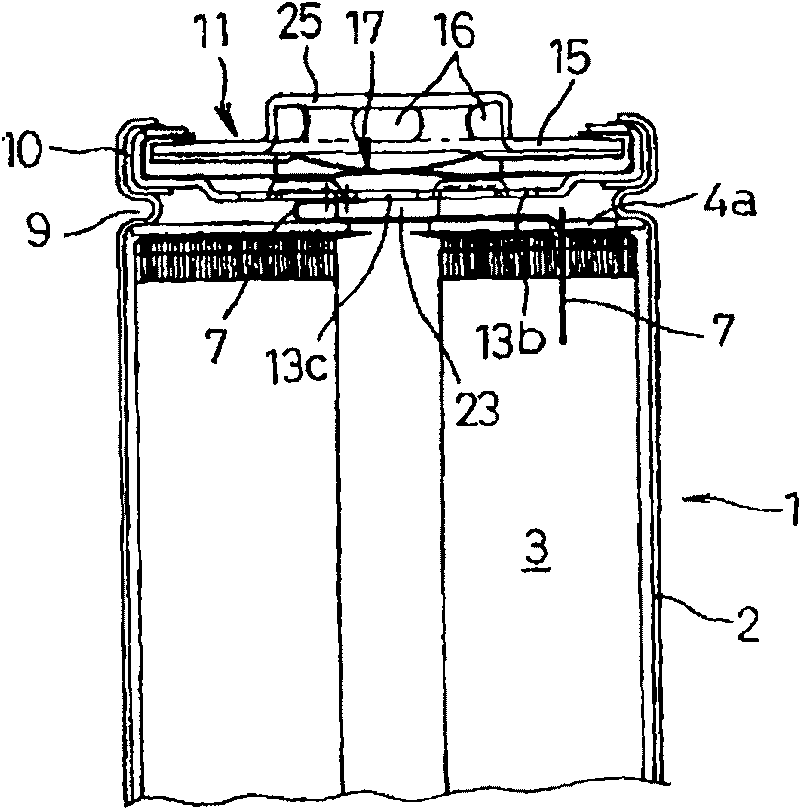

[0034] Below, refer to Figure 1 ~ Figure 8B One embodiment of the secondary battery of the present invention will be described.

[0035] exist Figure 1 ~ Figure 3 Among them, 1 is a cylindrical secondary battery composed of a lithium ion battery, and an electrode plate group 3 serving as a power generating element is accommodated together with an electrolytic solution in a bottomed cylindrical battery case 2 . The electrode plate group 3 is formed by winding the strip-shaped positive electrode plate, separator, negative electrode plate, and separator on the outer periphery of the winding core member in a state of being stacked in sequence, and pulling out the winding core member after the winding is completed. It is a structure in which a positive electrode plate and a negative electrode plate are stacked with a separator interposed therebetween. The separator protrudes upward and downward with an appropriate size from the positive electrode plate and the negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com