Method for manufacturing afebrile array wave-guide grating based on flat-plate wave-guide movement and delicate adjustment device

A technology of arrayed waveguide gratings and waveguide gratings, applied in the coupling of optical waveguides, etc., can solve problems such as difficult and accurate guarantee of height, insertion loss spectral characteristics, complex process, etc., to improve wavelength adjustment accuracy, ensure constant focal length, and spectral perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The method and fine-tuning device for fabricating athermal arrayed waveguide gratings based on the movement of slab waveguides of the present invention will be described in detail below with reference to the embodiments.

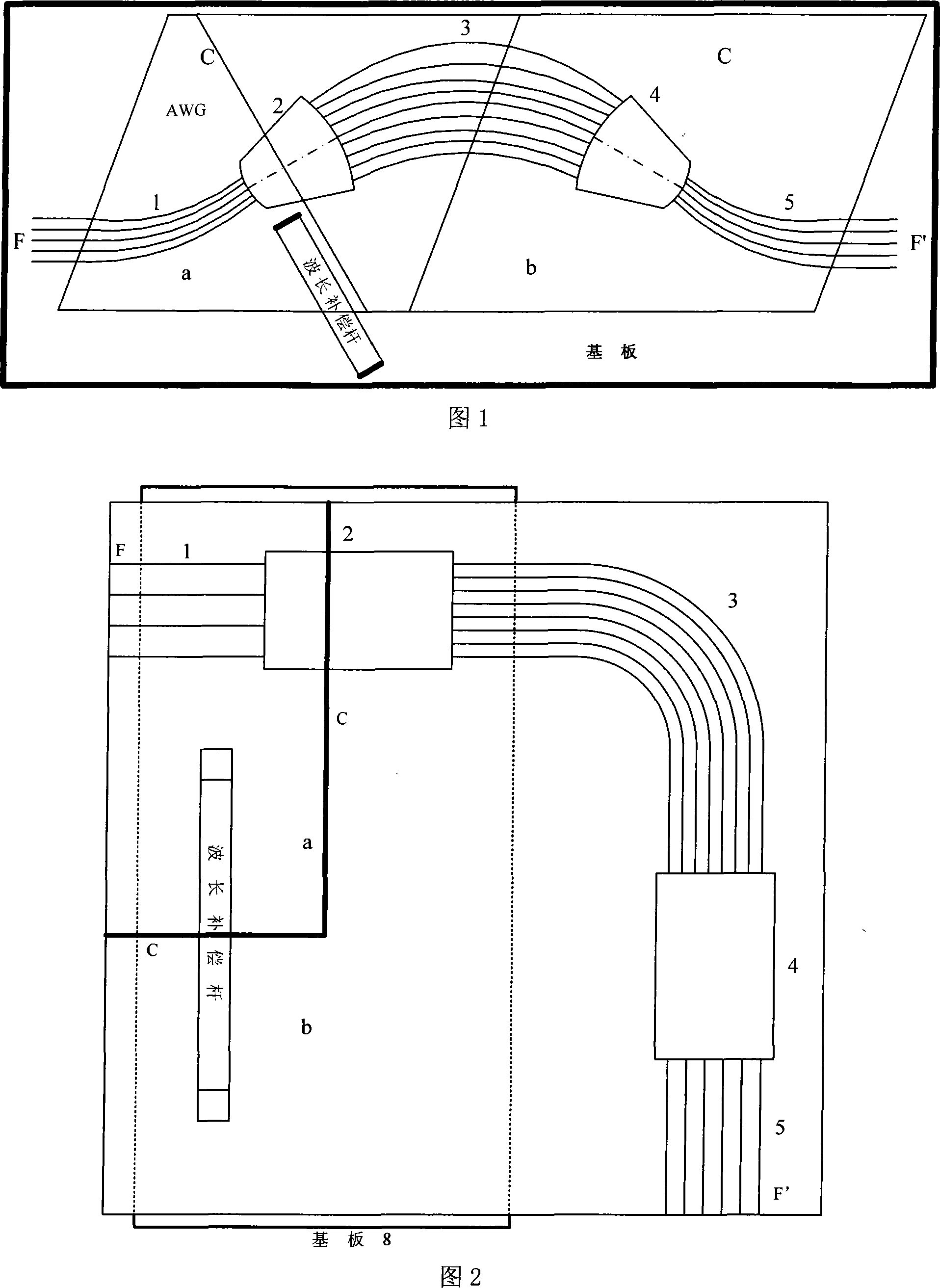

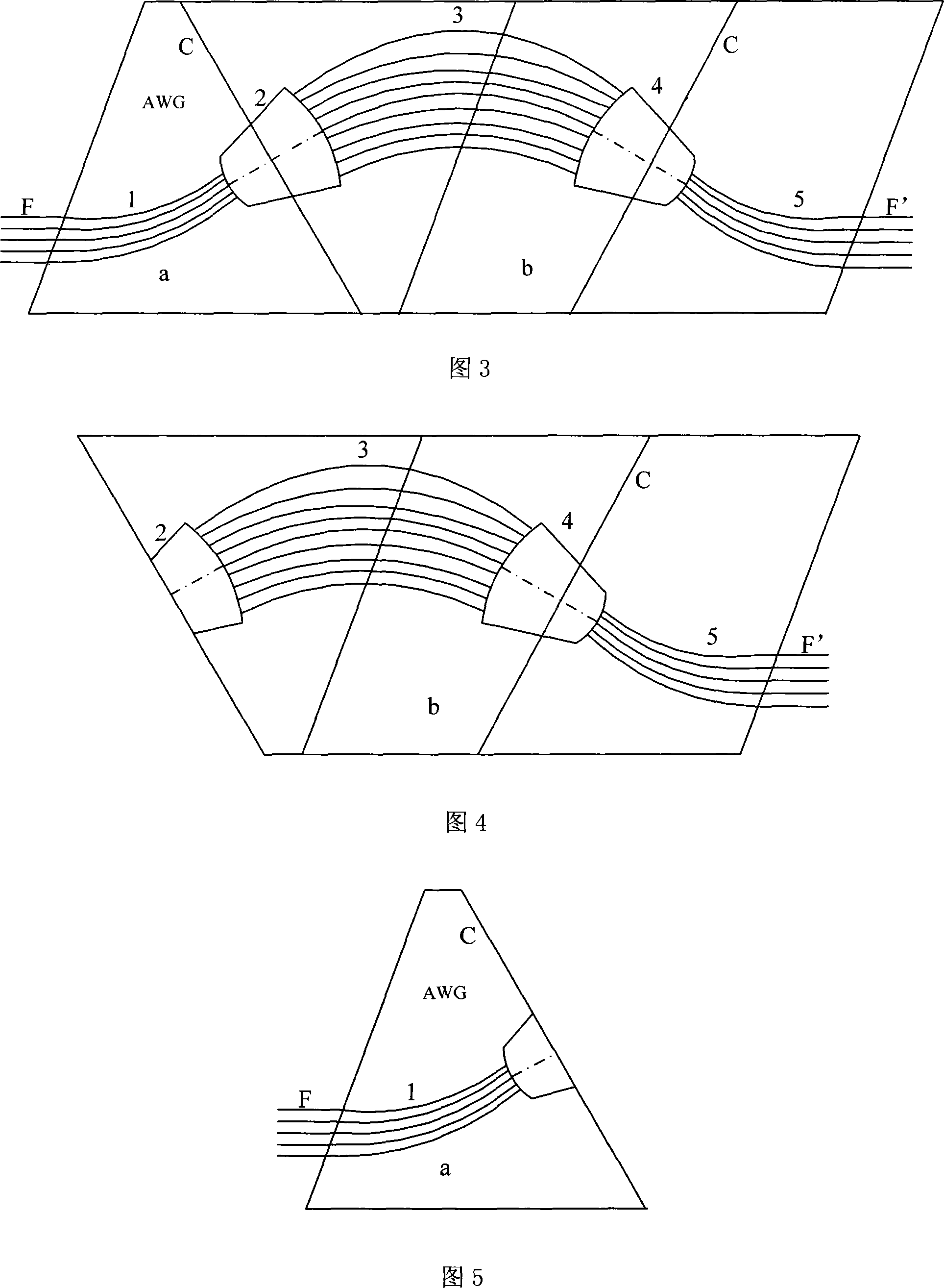

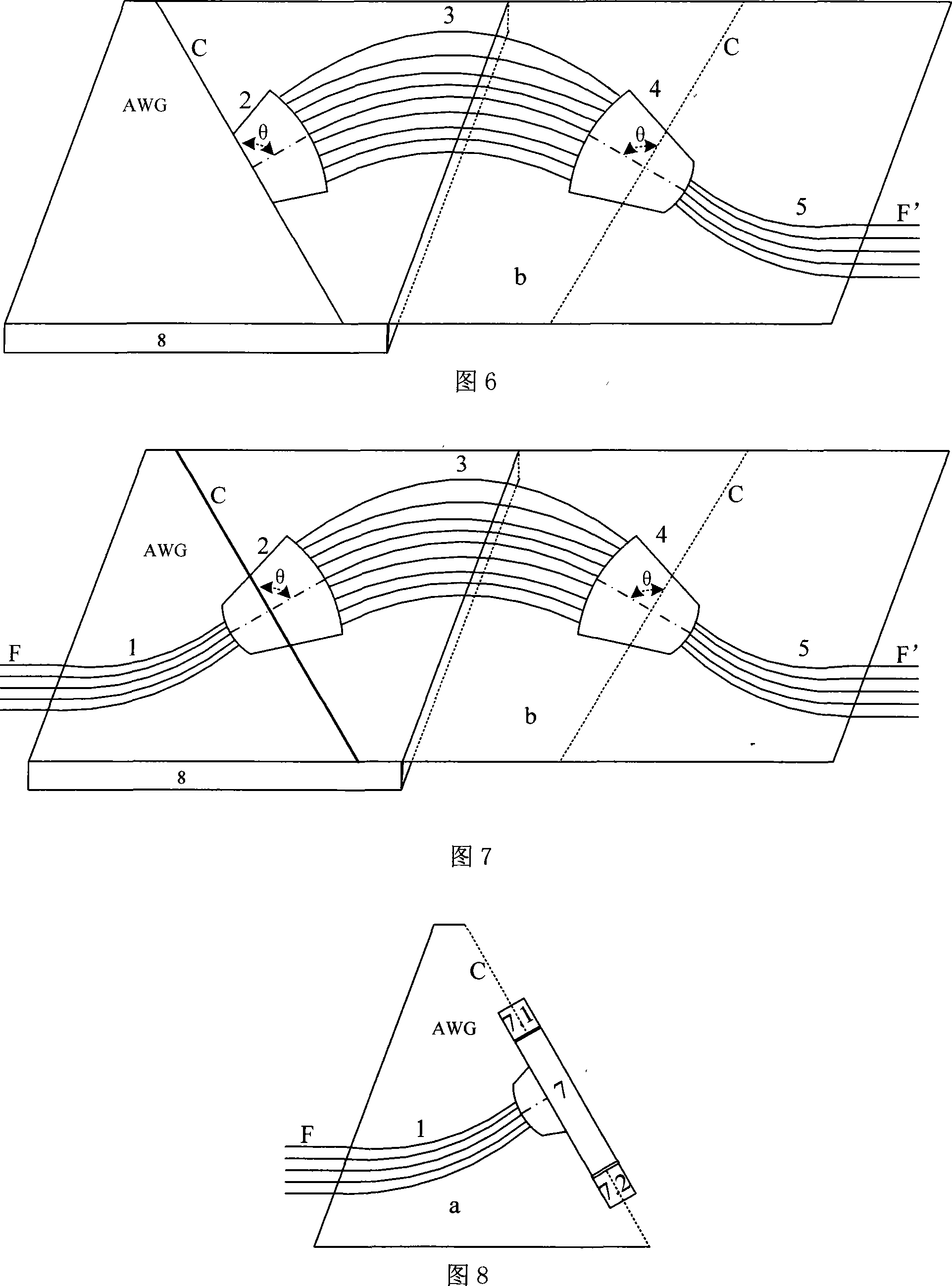

[0052] The present invention is to divide the chip into two parts a and b along the cutting line C on the input slab waveguide or the cutting line C on the output slab waveguide on the common silicon-based silicon dioxide AWG chip made by the planar optical waveguide technology. a includes the input waveguide 1 and a part of the input slab waveguide 2 , and part b includes the remaining part of the input slab waveguide 2 , the arrayed waveguide 3 , the output slab waveguide 4 and the output waveguide 5 . The substrate 8 is placed under the two parts a and b of the AWG chip to play a role of fixing and supporting. The temperature compensation rod 6 is placed across the cutting line of the AWG chip, and the glass baffle at one end of the temperature comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com