Hyperthermia steam hot wind convection type electric steaming furnace

A high-temperature steam and electric steam oven technology, applied in the field of electric steam oven, can solve the problems of disordered hot air convection and not achieving the best effect, and achieve the effect of simple and reasonable structure, uniform heating and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

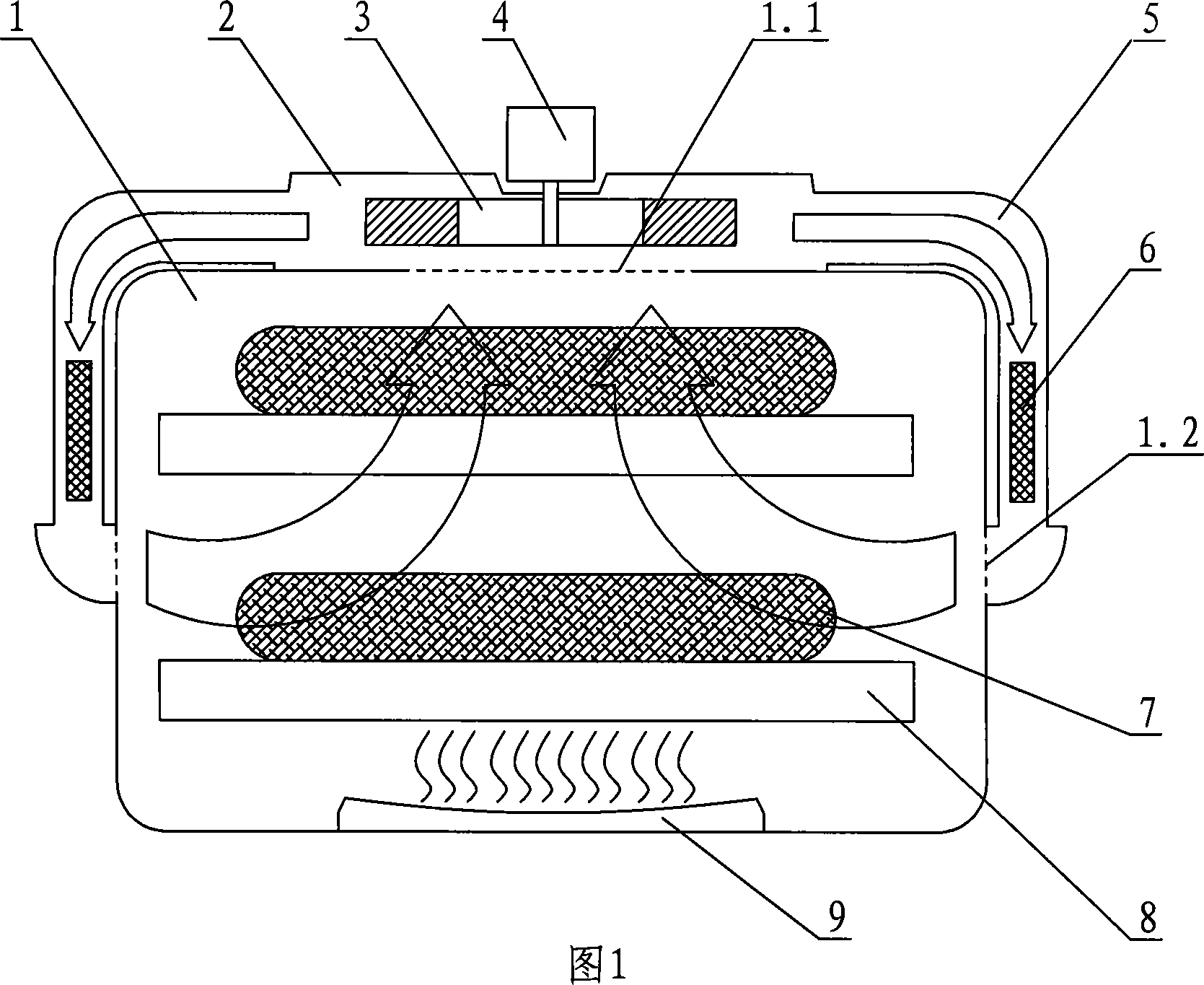

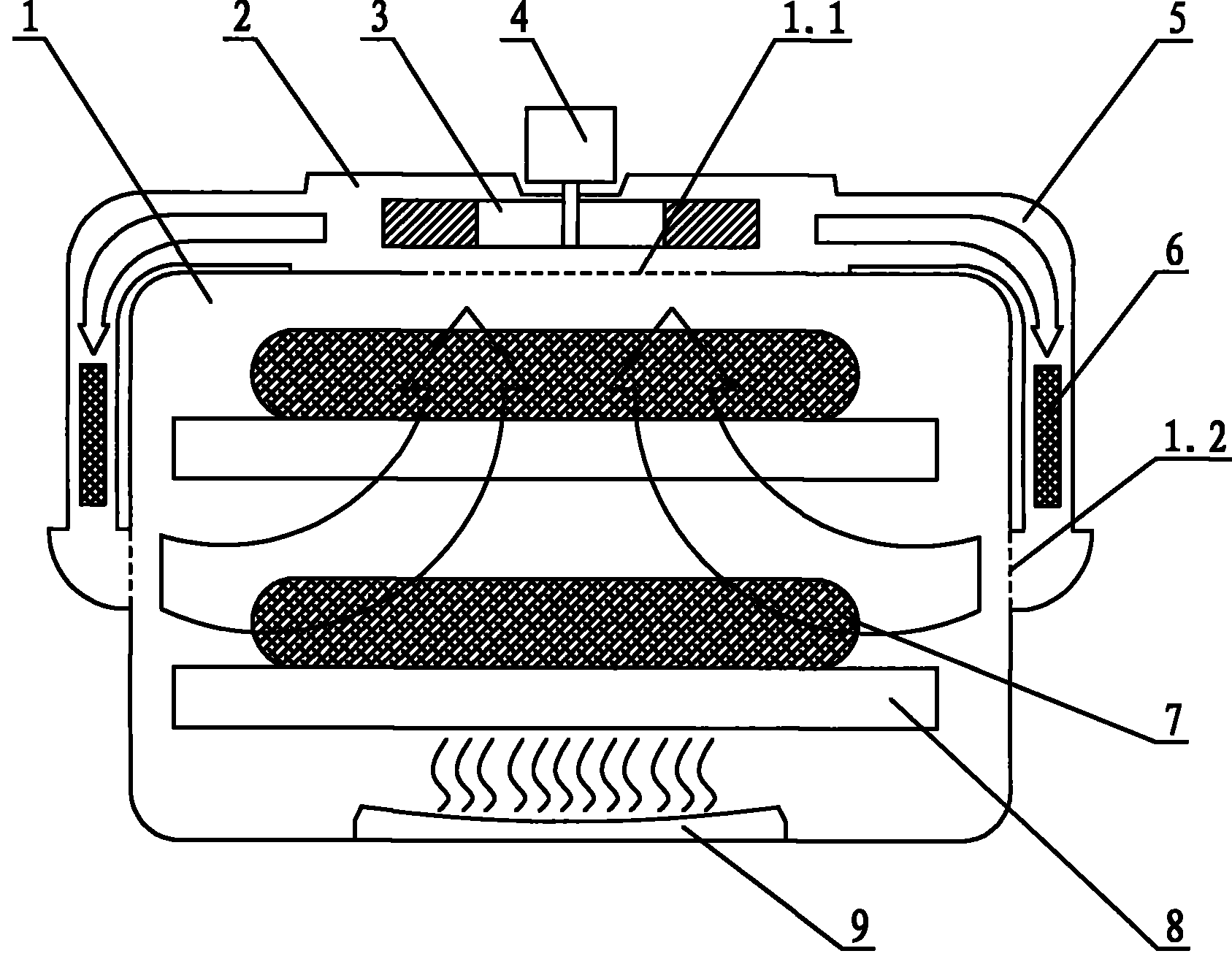

[0012] Referring to FIG. 1 , the high-temperature steam hot air convection electric steam oven includes a furnace cavity 1 , a steam generator 9 , a steam suction cover 2 , a dry burning pipe 6 and an air duct 5 . The steam generator 9 is arranged at the bottom of the oven cavity 1, and the oven cavity is provided with two layers of grid-shaped or net-shaped food supports 8, and the top is provided with a steam suction cover 2, and correspondingly provided with an open part 1.1 to communicate with it. The middle part is provided with a mesh 1.2, which communicates with the air duct 5, and the other end of the air duct communicates with the side of the steam inhalation hood. The dry burning pipe 6 is arranged in the port where the gas guide pipe 5 is connected to the furnace chamber 1 . A centrifugal fan 3 is arranged in the steam suction cover, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com