Tractive pulley element for a jacquard machine

A pulley block, jacquard machine technology, applied in the direction of jacquard machine, textile, textile and paper making, etc., to achieve the effect of small weight, half weight, and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

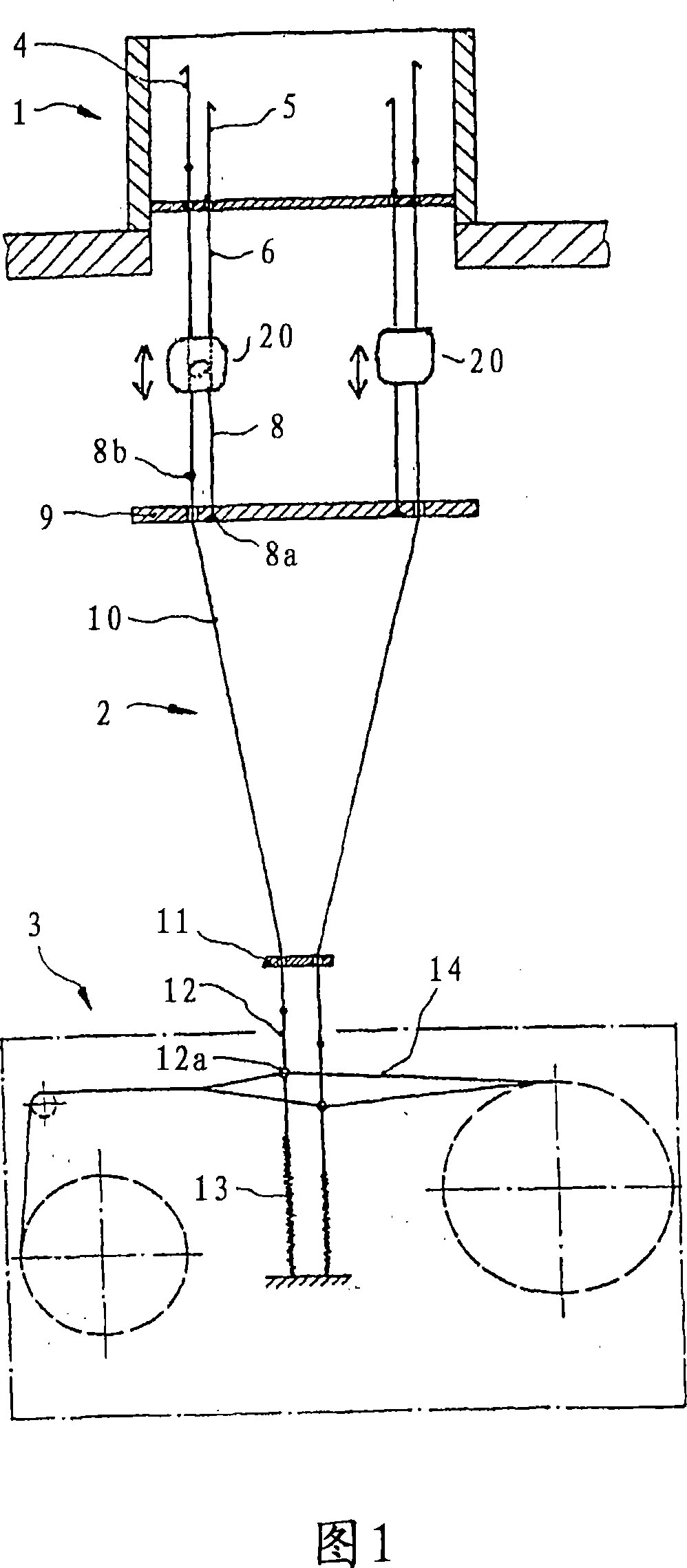

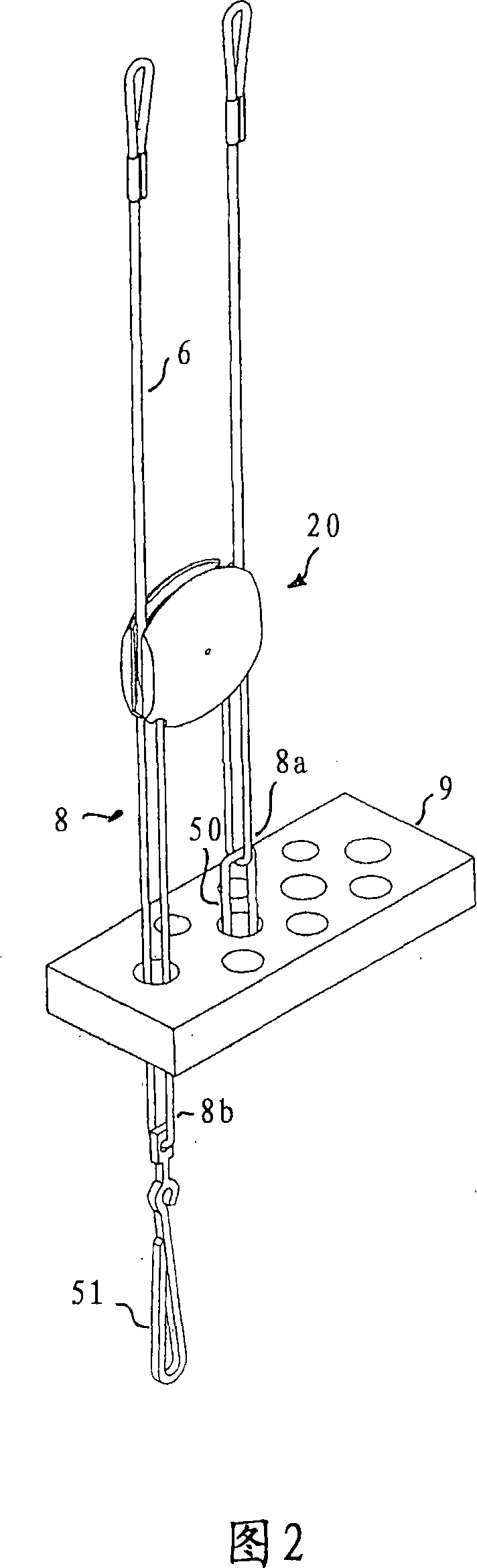

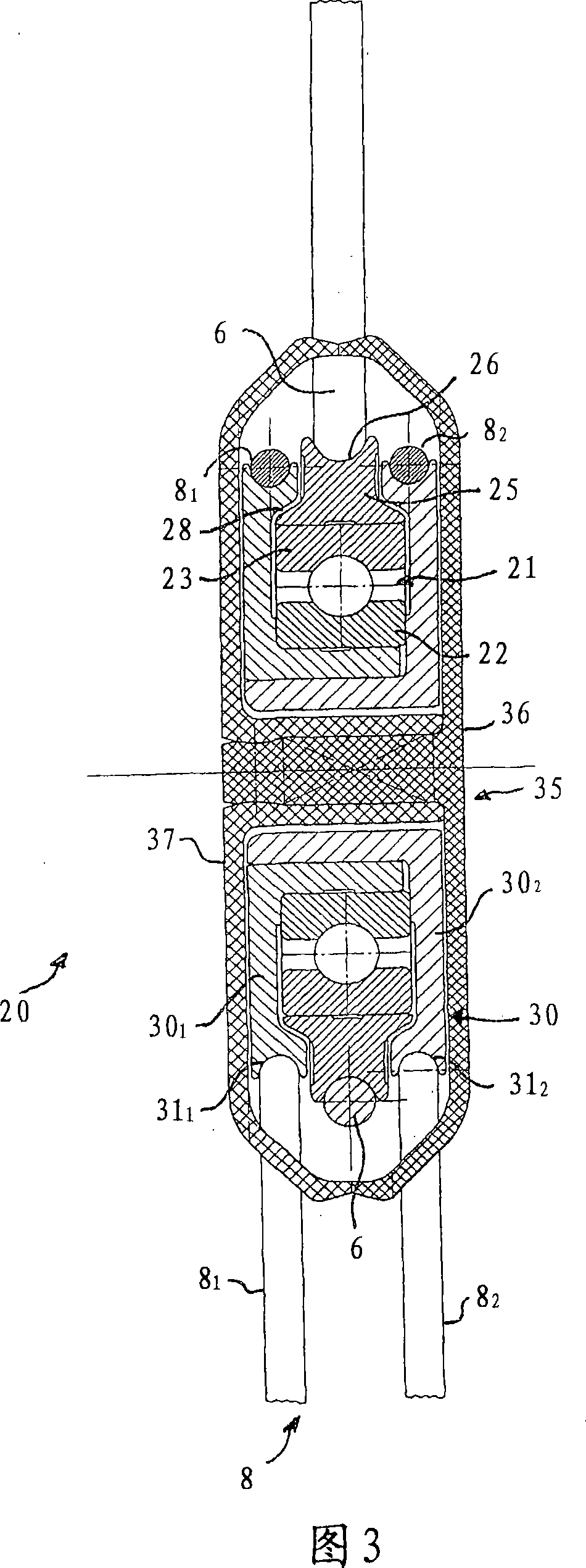

[0020] The basic construction of a Jacquard loom is sufficiently known that only a brief overview will be given below. figure 1 The weaving equipment shown in basically comprises parts known per se: Jacquard loom 1, harness 2 and loom 3, which are only schematically shown in figure 1 middle. In particular, only the associated carabiners 4 and 5 , which are connected to one another via a first looper 6 , are shown for the Jacquard machine provided with reference 1 . The looper 6, such as figure 1 , shown only schematically, extends via the pulley block part 20 according to the invention. on the contrary, figure 1 Not shown is the control device of the jacquard machine 1 , by means of which the lifting and lowering of the carabiners 4 and 5 is carried out and their controlled support in an upper position or a lower position is also ensured. Devices which can realize this are likewise sufficiently known from the prior art. Reference is made in this regard in particular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com