Optical fiber distributed temperature and stress sensing device

An optical fiber distributed, stress sensing technology, applied in the field of sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

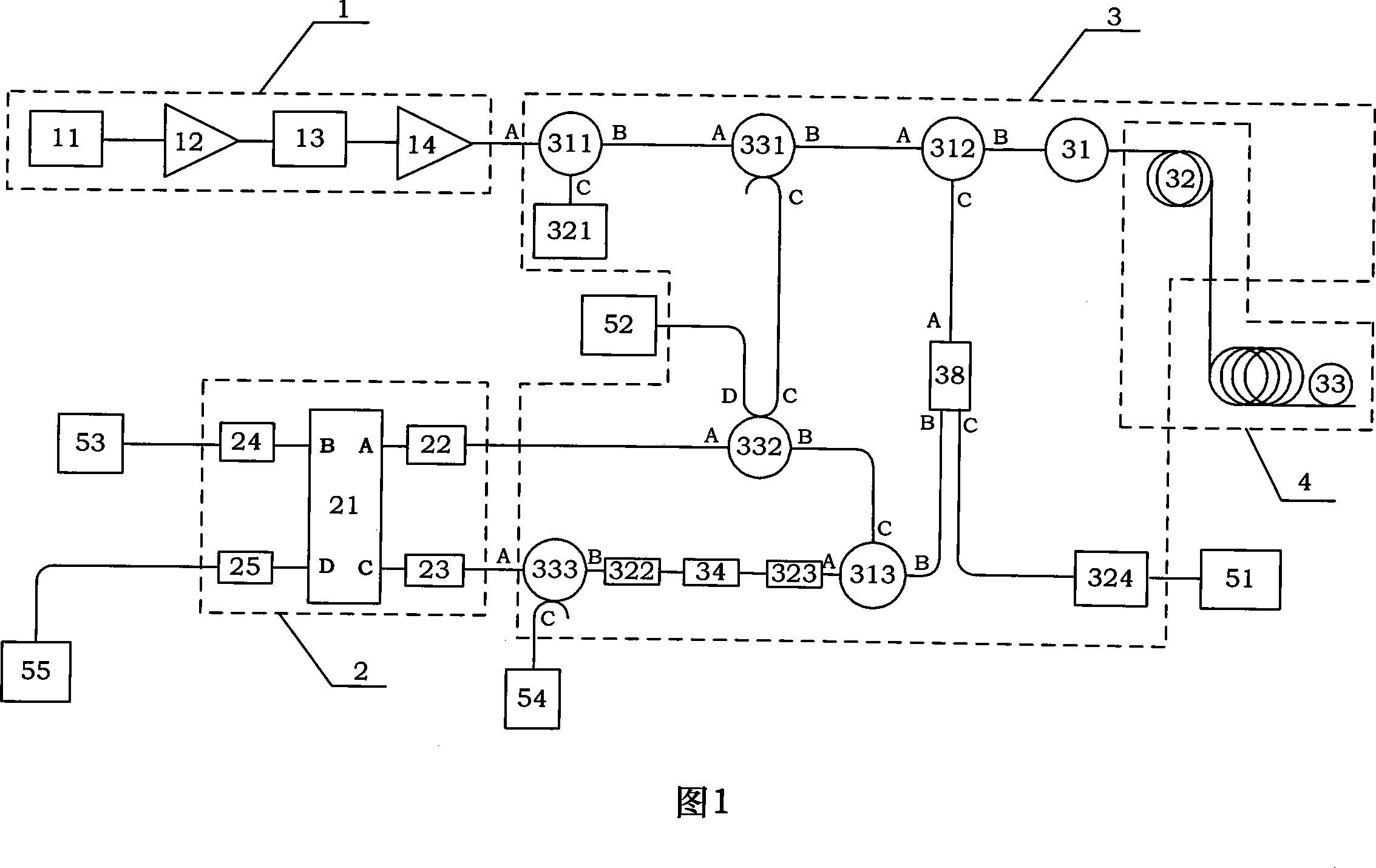

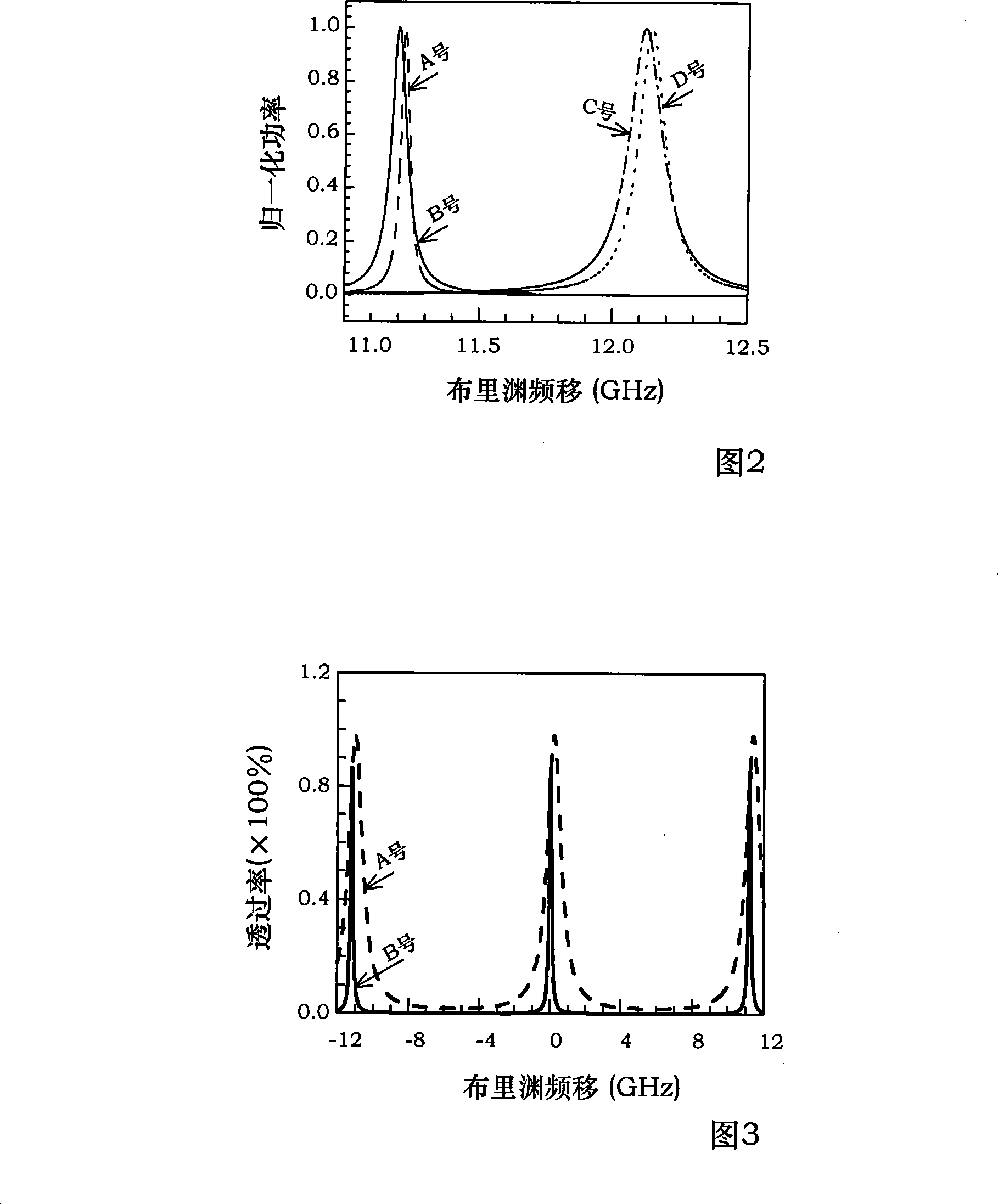

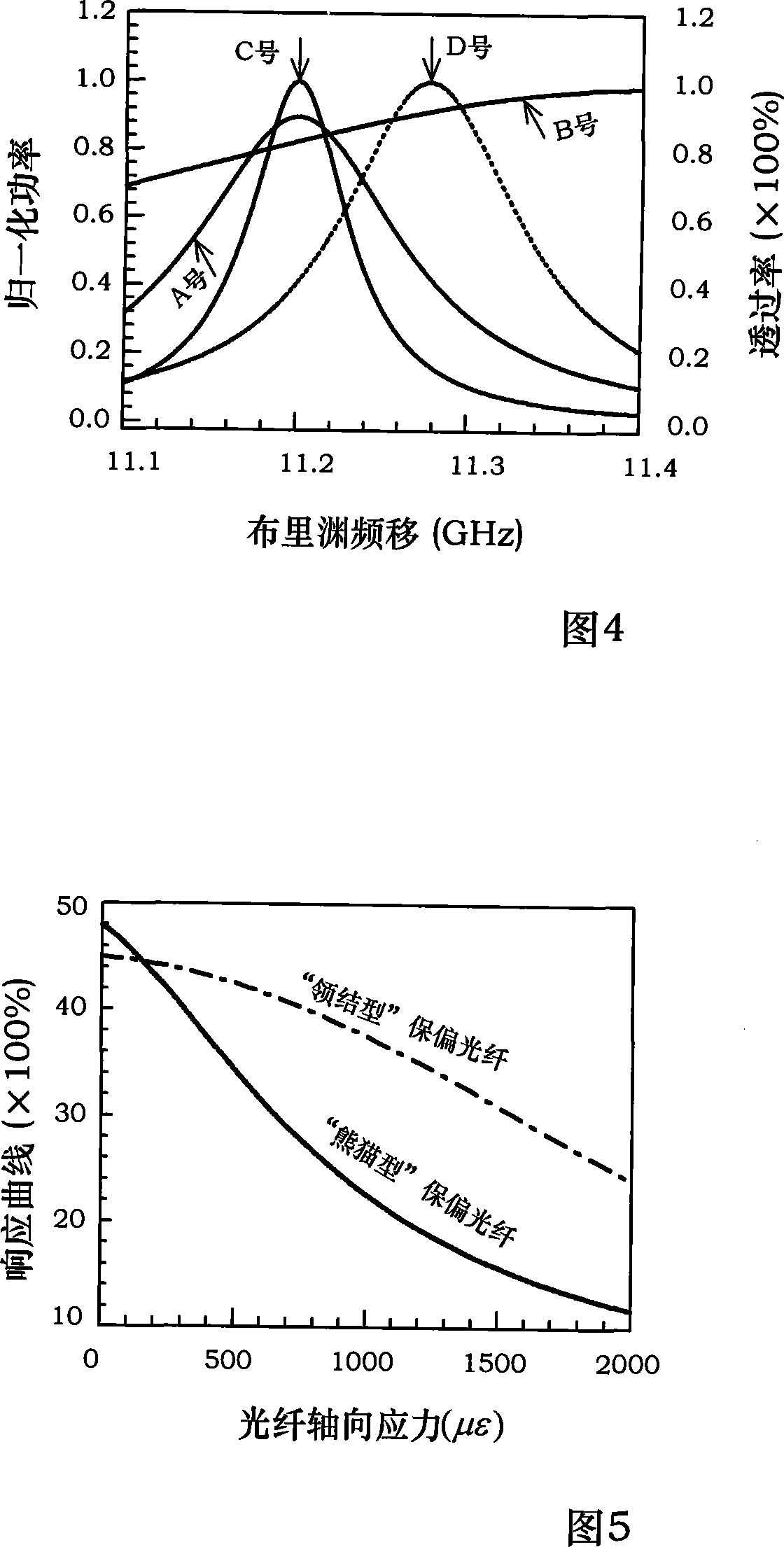

[0013] Please refer to Fig. 1, the present invention is an optical fiber distributed temperature and stress sensing device, based on optical fiber Raman scattering as temperature information carrier, Brillouin scattering as stress information carrier, using Rayleigh scattering to measure the relative Discriminator frequency and frequency offset, using Fabry-Perot etalon for frequency discrimination, and a direct detection method for simultaneous distributed sensing of temperature and stress. It mainly includes three modules: a light source 1, a frequency discriminator 2, and a constant temperature box 3. The connection relationship of the devices in each module is: the fiber laser 11 output pigtail and the first erbium-doped fiber amplifier 12 The input fiber fusion splicing, the first The fiber pigtail of the erbium-doped fiber amplifier 12 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com