Pneumatic power fluid-control type clutch automatic control device

An automatic control, pneumatic and hydraulic control technology, applied in the field of clutch control system, can solve the problems affecting the clutch control accuracy and response characteristics, affecting the efficiency of the mechanism, compact structure, low control accuracy, etc., achieving simple structure, fast response speed, control high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

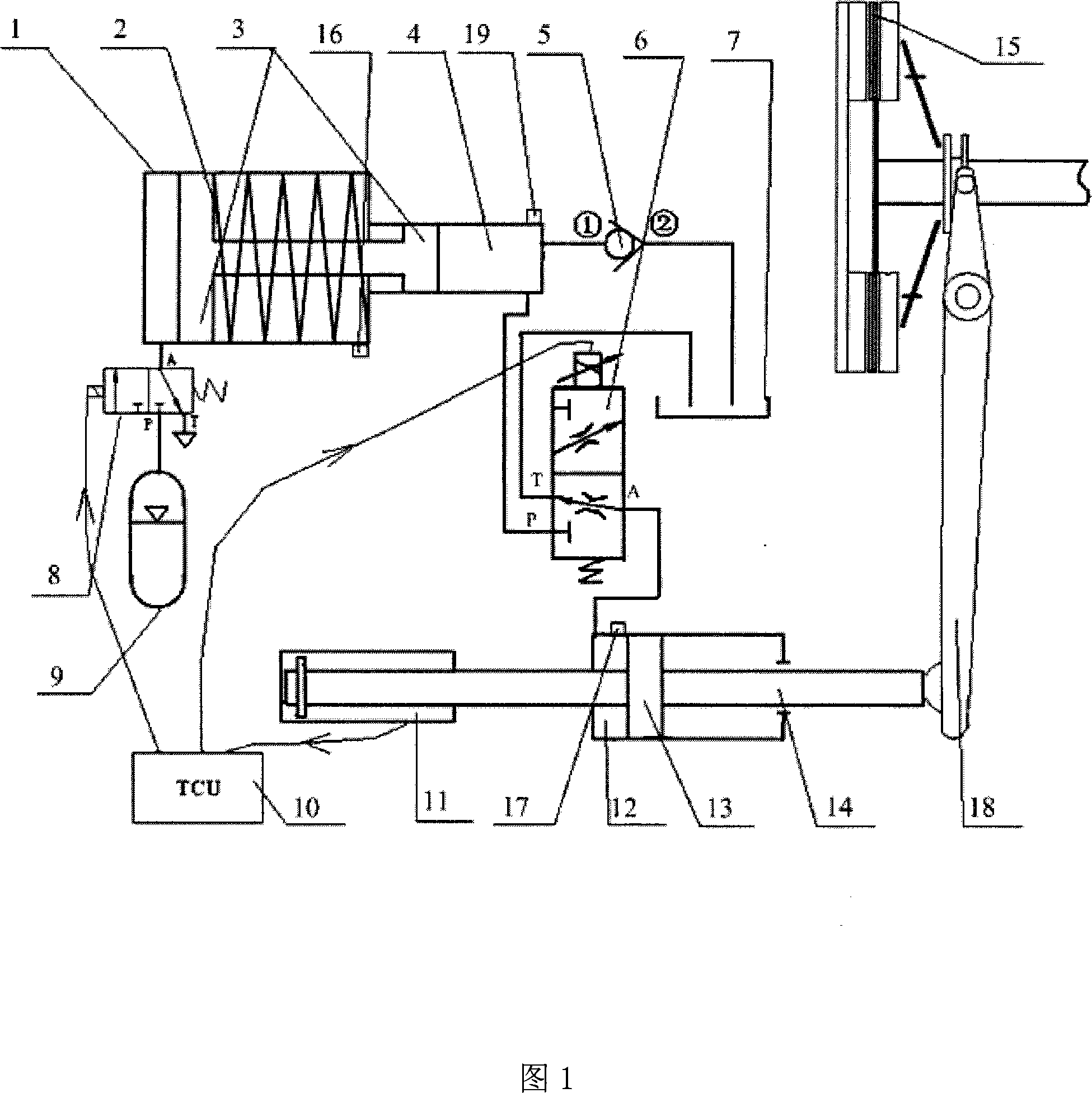

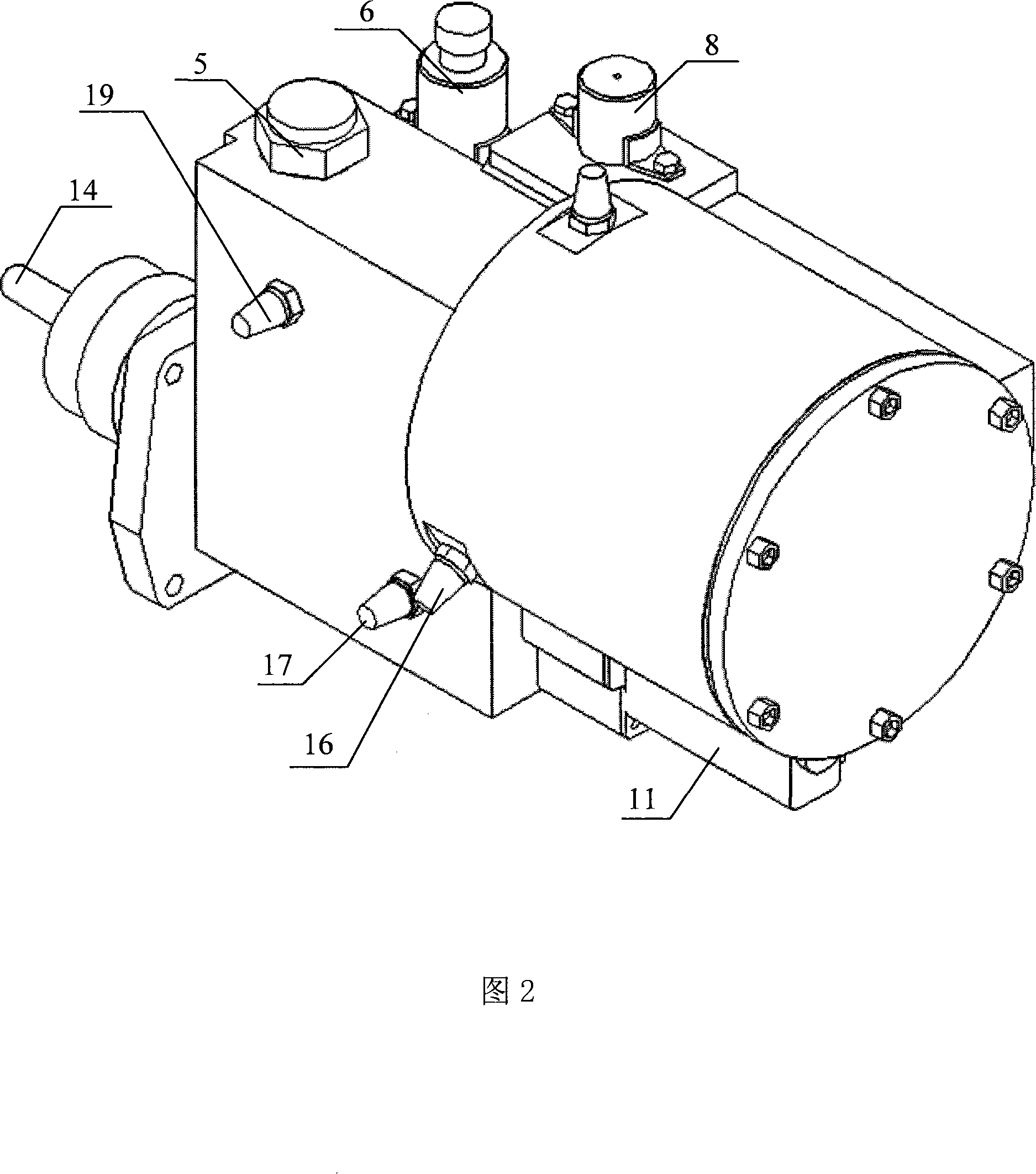

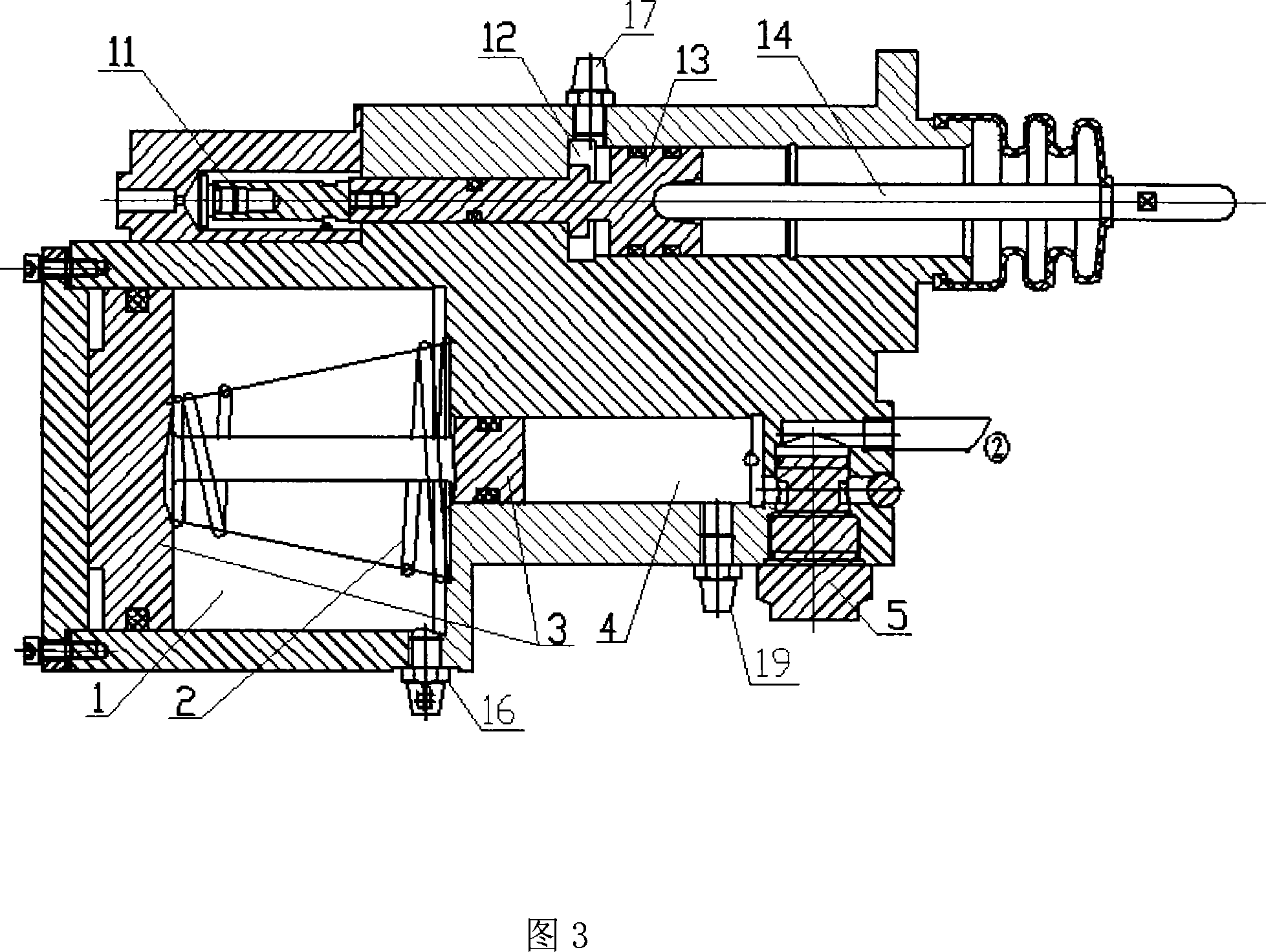

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025] Referring to Fig. 1 to Fig. 3, the present invention provides a pneumatic hydraulic clutch automatic operating device. It mainly solves the technical problems of large volume, slow response and low control precision of the pure pneumatic clutch control device. At the same time, it solves the partial design problems such as the installation of the clutch sensor and the oil supply of the system, and decomposes the clutch separation and engagement into two independent processes. It avoids the impact of the damping of pneumatic components on the precision of hydraulic control, and effectively improves the position and speed control precision and response speed of the joint process. The device has the characteristics of simple structure, compact structure, good processing technology and fast response speed. This device is more suitable for vehicles with compressed air sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com