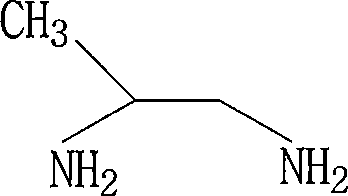

Method for synthesizing 1,2-propane diamine

A synthesis method and technology of propylenediamine, applied in the first field, can solve the problems of large consumption of raw materials, serious corrosion of equipment, and many wastes, etc., achieve the effects of reducing production costs, meeting the needs of industrialization, and increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of propylene diamine.

[0021] Add 10mol isopropanolamine and 22.5g Raney Ni catalyst into the reactor, replace the air in the reactor with hydrogen, pass a little hydrogen through 12mol anhydrous ammonia, raise the temperature to 150°C, continue to feed hydrogen to 10MPa, and keep the pressure at 10MPa, react for 10h. After the reaction was completed, the reaction solution was cooled, the water was evaporated under normal pressure, and then vacuum distillation was performed to obtain 6.8 mol of pure propylenediamine.

Embodiment 2

[0022] Embodiment 2: the preparation of propylene diamine.

[0023] Add 10mol isopropanolamine and 22.5g Pd / C catalyst into the reactor, replace the air in the reactor with hydrogen, pass a little hydrogen through 12mol anhydrous ammonia, raise the temperature to 150°C, continue to feed hydrogen to 10MPa, and keep Pressure at 10MPa, react for 10h. After the reaction was completed, the reaction liquid was cooled, the water was evaporated under normal pressure, and then vacuum distillation was performed to obtain 6.6 mol of pure propylenediamine.

Embodiment 3

[0024] Embodiment 3: the preparation of propylene diamine.

[0025] Add 10mol isopropanolamine, 22.5g Raney Ni catalyst and 0.5mol water into the reactor, replace the air in the reactor with hydrogen, pass a little hydrogen through 13mol anhydrous ammonia, raise the temperature to 180°C, and continue to feed hydrogen to 11MPa , keep the pressure at 11MPa, and react for 12h. After the reaction was completed, the reaction liquid was cooled, and the water was evaporated under normal pressure, and then vacuum distillation was performed to obtain 6.4 mol of pure propylenediamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com