Single piece type seamless bra and its preparation method

A technology for seamless bras and bras, applied to bras, clothing, brassieres, etc., can solve the problems of affecting the aesthetic effect, the production method is too simple, not very comfortable, etc., to reduce production costs, reasonable production methods, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

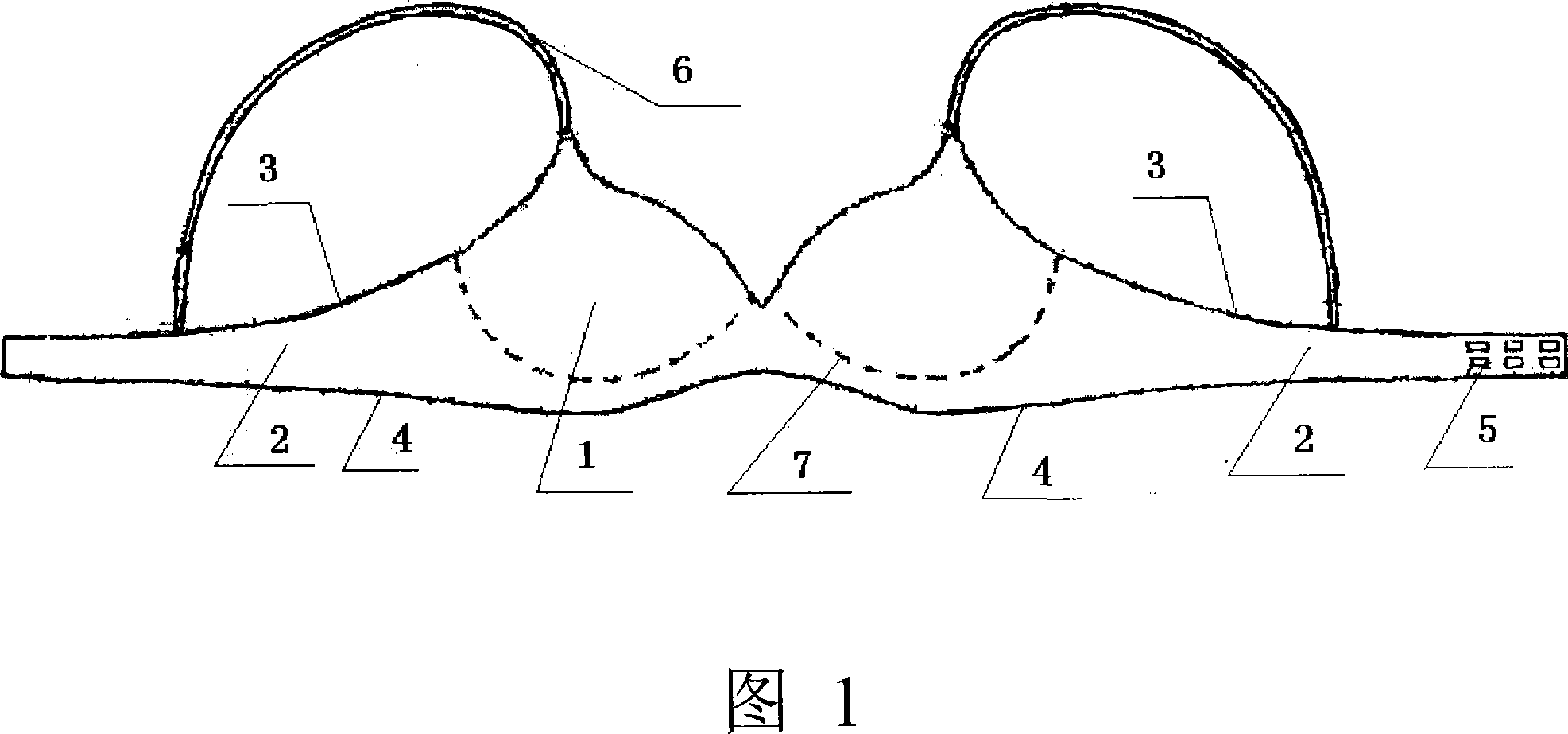

[0024] As shown in Fig. 1 , the brassiere involved in the present invention includes a cup body 1, side wings 2, upper waist circumference 3, lower waist circumference 4, back buckle 5, and shoulder straps 6. The cup body 1 is composed of fabric, cup body built-in elastic body and base material. The underside of the cup body built-in elastic body is placed along the edge of the cup body 1. Steel ring 7, except for the shoulder strap 6, the whole bra is integrally formed in one piece without sewing and stitching.

[0025] When making:

[0026] (a) Use 3D software to draw a bra simulation map, and process a bra mold on a CNC machine tool according to the simulation map.

[0027] (b) According to the bra mold data, process the hand-push mold with built-in elastic body in the cup.

[0028] (c) Cut a square sponge on the CNC machine according to the bra mold data, and use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com