Printed circuit board

A technology for wiring circuit substrates and dielectric constants, which can be applied to printed circuits, printed circuits, circuit devices, etc., and can solve problems such as loss and reduced signal transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, a printed circuit board according to an embodiment of the present invention will be described with reference to the drawings. The printed circuit board of this embodiment is a flexible printed circuit board.

[0034] (1) Manufacturing method of printed circuit board

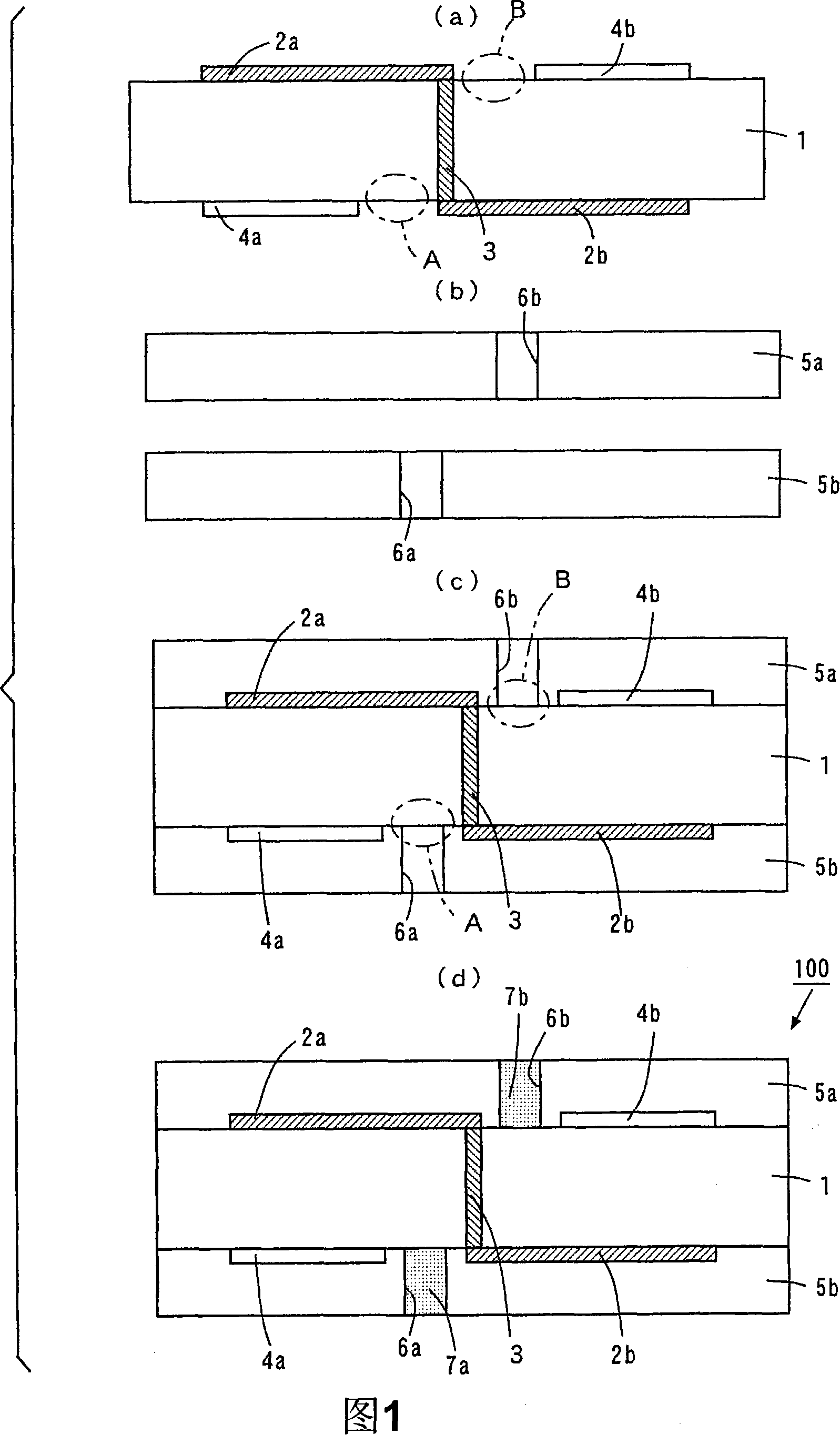

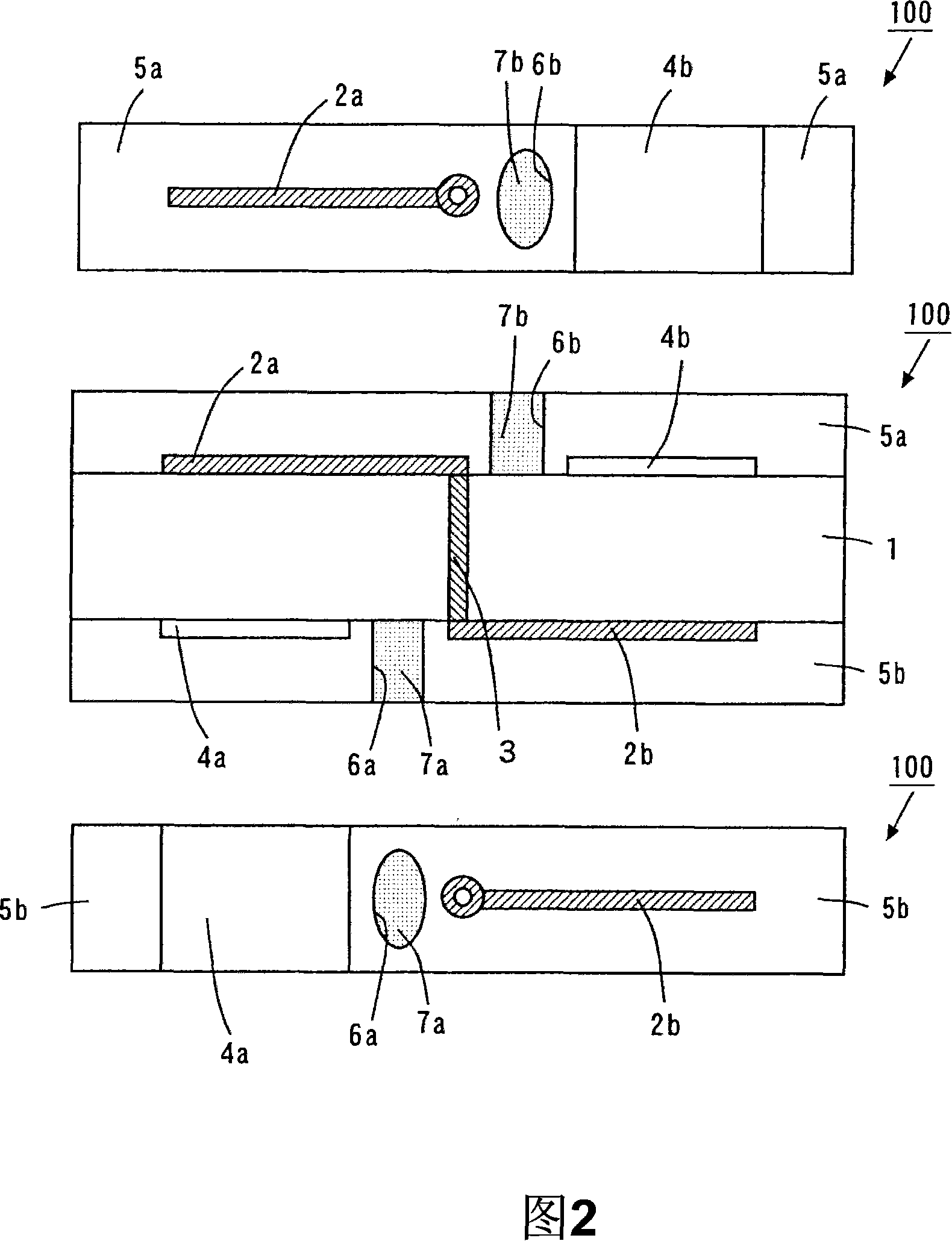

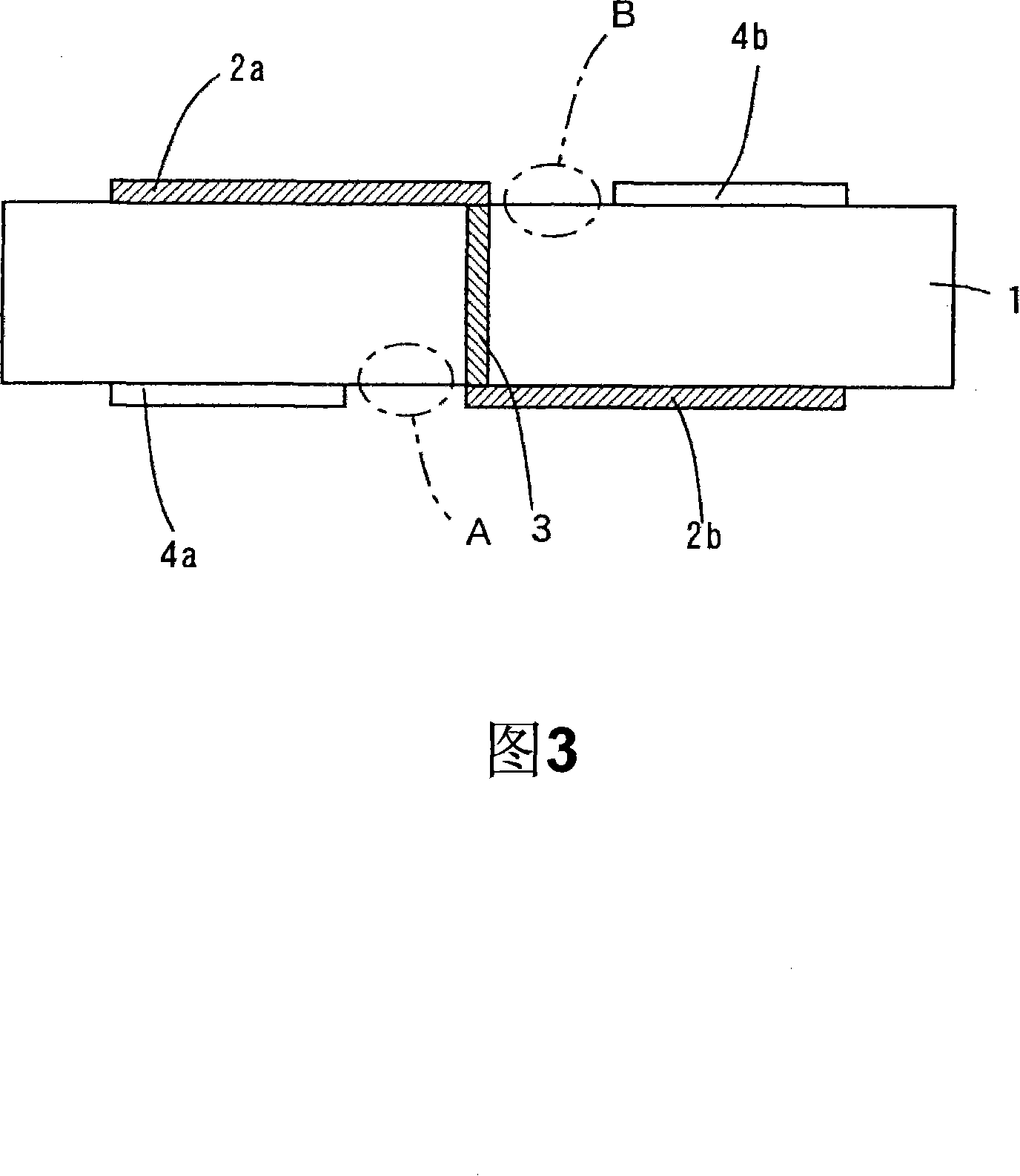

[0035] FIG. 1 is a schematic process cross-sectional view showing an example of a method of manufacturing a printed circuit board according to the present embodiment.

[0036] As shown in FIG. 1(a), predetermined wiring patterns 2a, 2b made of, for example, copper are respectively formed on one side and the other side of an insulating base layer 1 made of, for example, a polyimide film. In addition, base insulating layer 1 made of epoxy resin, acrylic resin, or butyral resin may also be used. In addition, the specific dielectric constant of the insulating base layer 1 is, for example, approximately 3.2 to 4.0.

[0037] In addition, a metal plating layer 3 for electrically connecting the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com