Refrigerator of pulse tube

A pulse tube and refrigerator technology, applied in refrigerators, gas cycle refrigerators, compressors, etc., can solve the problem of insufficient heat exchange, and achieve the effect of improving heat exchange efficiency and cooling characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Next, preferred embodiments for carrying out the present invention will be described with reference to the accompanying drawings.

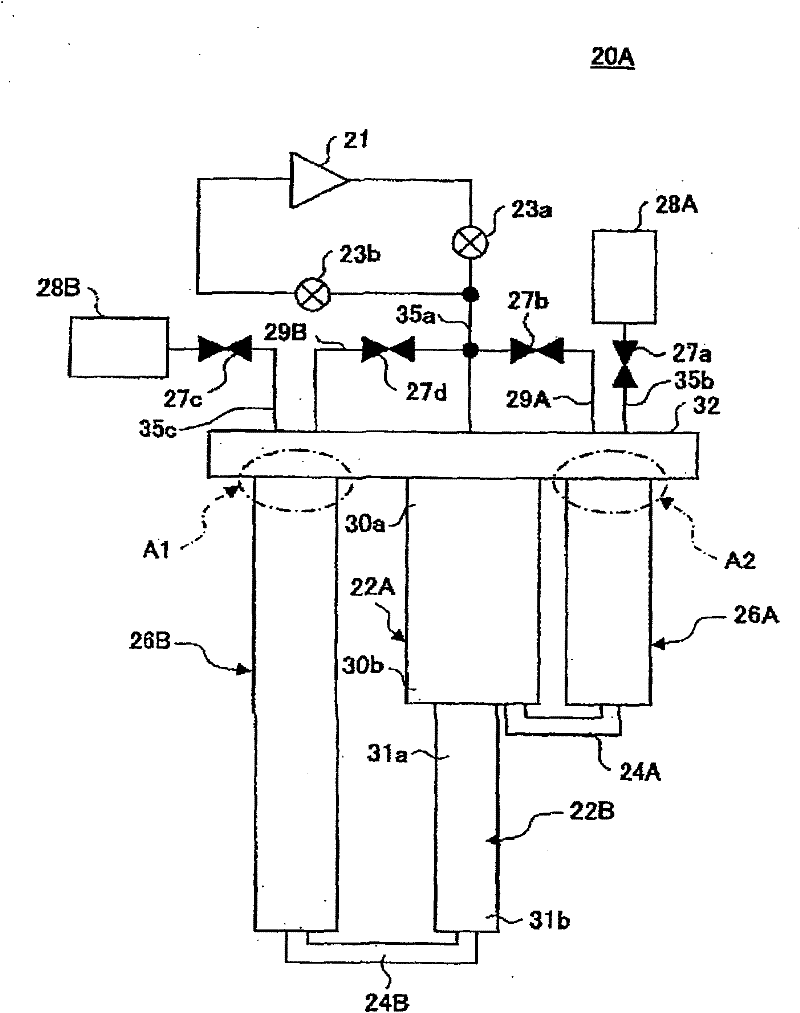

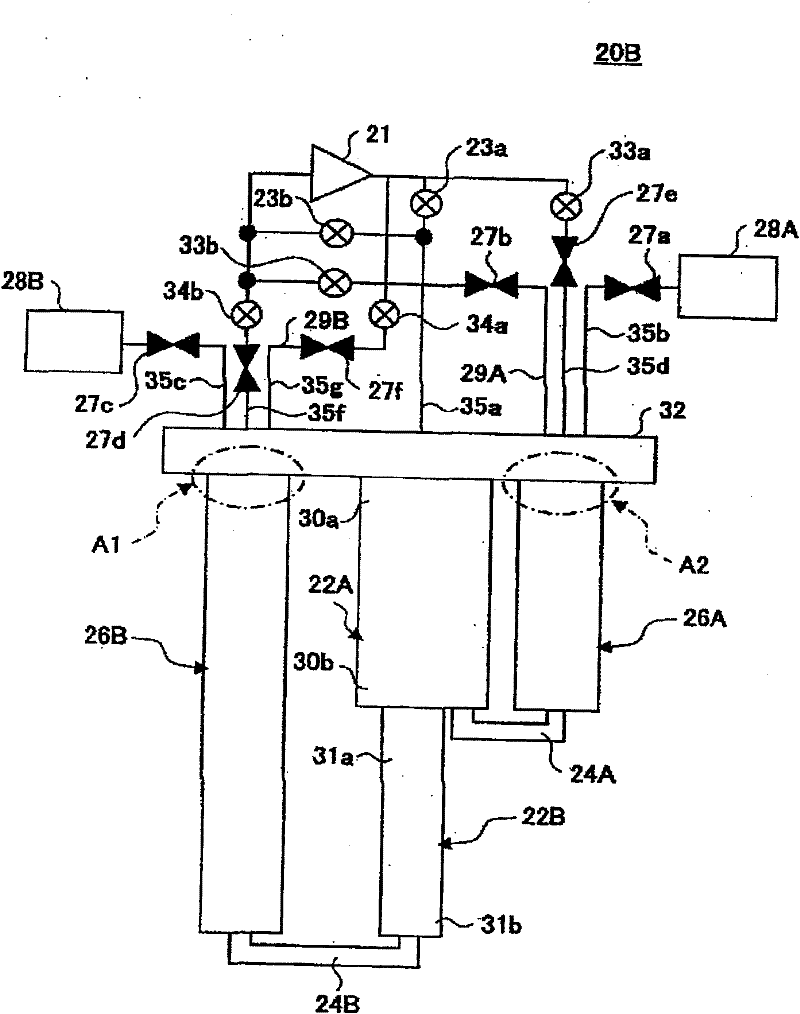

[0050] figure 1 and figure 2 The pulse tube refrigerators 20A and 20B which can implement the present invention are shown. figure 1 The pulse tube refrigerator 20A shown is a two-stage, dual input type pulse tube refrigerator, figure 2 The illustrated pulse tube refrigerator 20B is a two-stage, four-valve type pulse tube refrigerator. First, refer to figure 1 A two-stage double-input type pulse tube refrigerator 20A will be described.

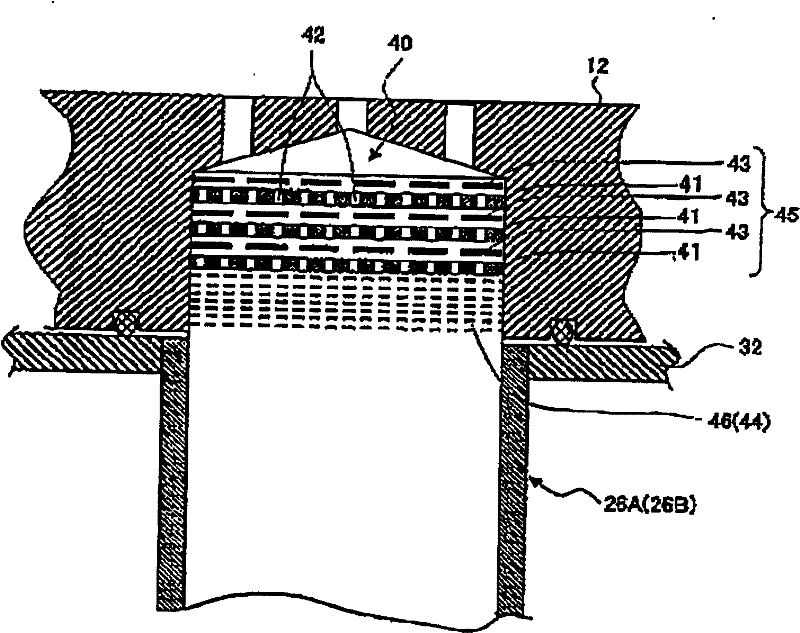

[0051]Since the pulse tube refrigerator 20A is a two-stage type, it has a first-stage regenerator 22A and a second-stage regenerator 22B as regenerators, and also has a first-stage pulse tube 26A and a second-stage pulse tube as pulse tubes. 26B. The high-temperature portion 30 a of the first-stage regenerator 22A, the upper end portion of the first-stage pulse tube 26A, and the upper end portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com