Method for producing product by combination of continuous fibre reinforced nylon and metal

A metal composite and continuous fiber technology, which is applied in the field of fiber reinforced nylon and metal material composite, can solve the problems of complex operation, poor bonding between resin and fiber interface, high energy consumption, etc., and achieve simple process, good impregnation effect and good stress transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

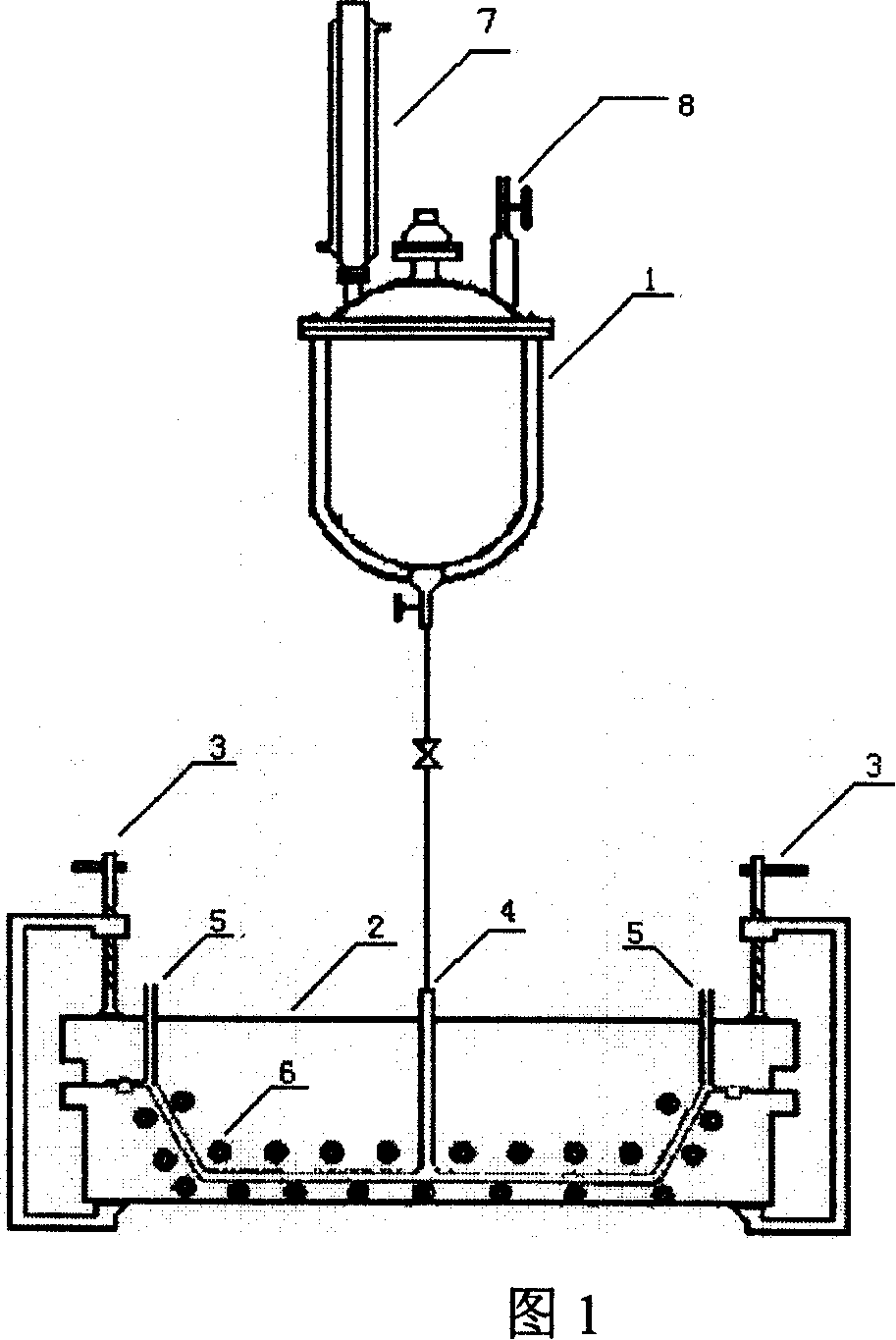

[0025] As shown in Figure 1, put caprolactam into the reactor 1 in sequence, add 2% defoamer and 2% NaOH, start the vacuum pump, start heating after the pressure is lower than 3mmHg, keep the pressure lower than 3mmHg throughout the process and the temperature reaches 108℃~ The melt was refluxed for 20 minutes at 116°C. Stop vacuuming when the uppermost end of the return line is hot. When the melt is heated to 132°C to 134°C, add TDI and stir well, spread the treated metal plate and glass felt (glass cloth or carbon fiber cloth) into the mold in turn, as shown in Figure 1, close the feeding pipe, start the vacuum pump, Vacuum the mold 2, when the pressure is lower than 3mmHg, open the feed pipe, and press the resin into the mold with high-pressure nitrogen at the same time, keep the mold temperature at 150°C-160°C, melt polymerize for 5-30 minutes, cool and demould Get products.

Embodiment 2

[0027] As shown in Figure 1, put caprolactam, 10% nylon 1212, 2% defoamer and 2% NaOH into the reactor in turn, start the vacuum pump, start heating after the pressure is lower than 3mmHg, keep the pressure lower than 3mmHg in the whole process and When the temperature reaches 160°C-200°C, keep the melt boiling until the nylon 1212 is completely dissolved, then add TDI into the reaction kettle and stir well. Lay the treated metal plate and glass mat (glass cloth or carbon fiber cloth) into the mold in turn, as shown in Figure 1, close the feeding pipe, start the vacuum pump, and vacuum the mold. After the pressure is lower than 3mmHg, open the feeding pipe, and at the same time Use high-pressure nitrogen to press the resin in the reaction kettle into the mold, keep the mold temperature at 160°C-200°C, melt polymerize for 5-30 minutes, cool and demould to obtain the product.

Embodiment 3

[0029] As shown in Figure 1, put caprolactam, 10% nylon 66, 2% defoamer and 2% NaOH into the reaction kettle in turn, start the vacuum pump, start heating after the pressure is lower than 3mmHg, maintain the whole process pressure below 3mmHg and When the temperature reaches 160°C-200°C, keep the melt boiling until the nylon 66 is completely dissolved, then add TDI into the reaction kettle and stir well. Lay the treated metal plate and glass mat (glass cloth or carbon fiber cloth) into the mold in turn, as shown in Figure 1, close the feeding pipe, start the vacuum pump, and vacuum the mold. After the pressure is lower than 3mmHg, open the feeding pipe, and at the same time Use high-pressure nitrogen to press the resin in the reaction kettle into the mold, keep the mold temperature at 160°C-200°C, melt polymerize for 5-30 minutes, cool and demould to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com