Radiator

A technology of radiator and heat dissipation area, applied in the direction of instruments, instrument cooling, electric solid devices, etc., can solve the problems of reducing the heat dissipation effect of the radiator 100, and achieve the effect of low impact and utilization of heat dissipation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

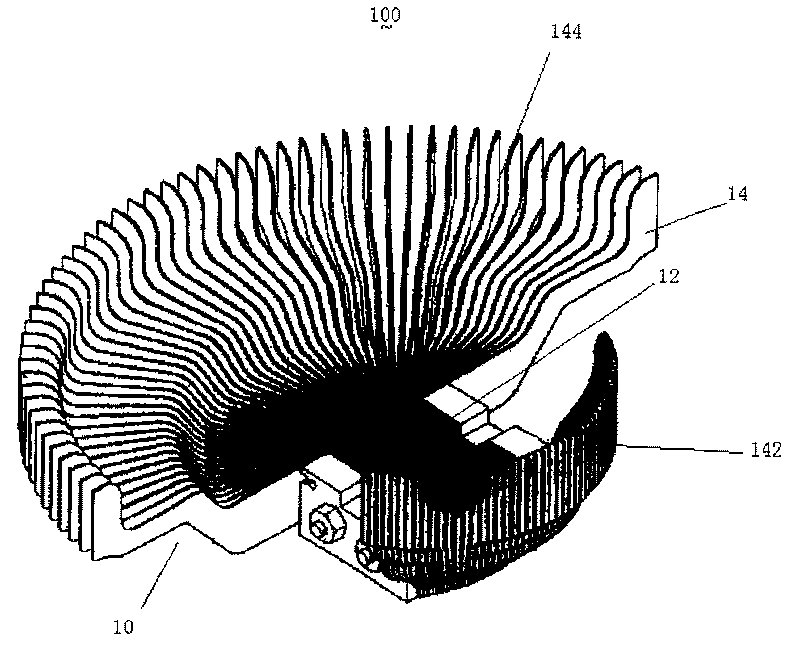

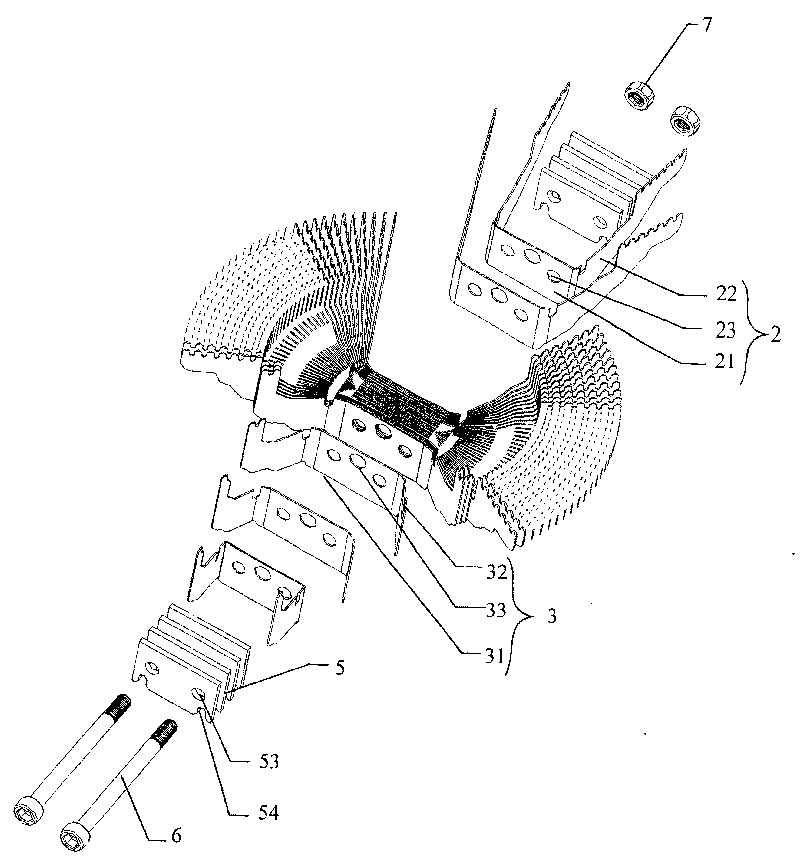

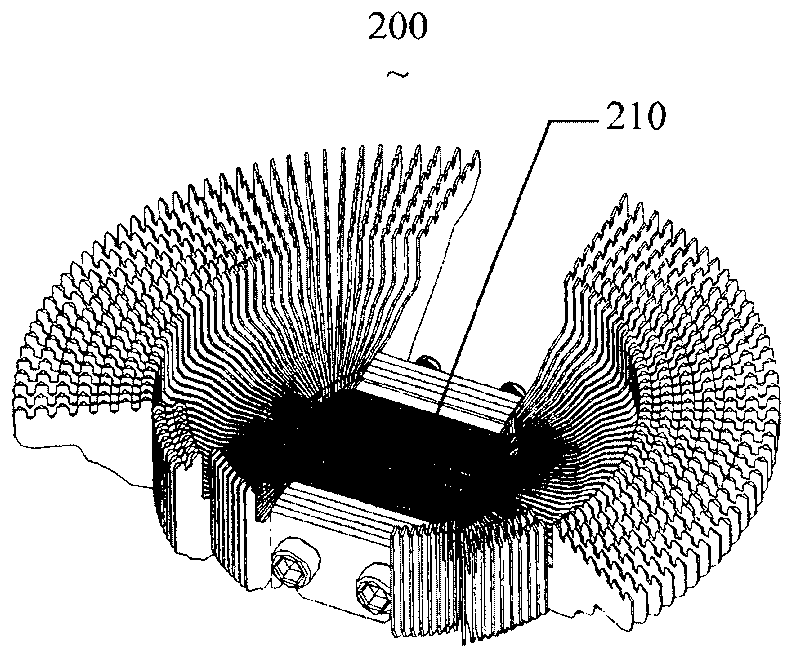

[0025] Please refer to figure 2 ~Figure 8, figure 2 It is a schematic diagram of the decomposition structure of the radiator of the present invention; image 3 is a schematic structural view of the radiator of the present invention; Figure 4 It is a schematic diagram of the overall structure of the combination of the radiator of the present invention and the device to be dissipated; Figure 5 It is a schematic structural diagram of a further improved embodiment of the radiator of the present invention; Figure 6 yes Figure 5 Schematic diagram of the breakdown structure; Figure 7 yes Figure 6 The enlarged structure diagram of the through hole 83 and the screw 87. The radiator 200 includes a main heat sink 2 , a secondary heat sink 3 , an extruded block 5 , bolts 6 , nuts 7 and a connecting seat 8 . The main heat sink 2 includes a heat absorption area 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com