High capacity underground oil storage

An oil storage, large-capacity technology, used in the fields of liquefied petroleum gas, crude oil, liquid chemical storage devices, and refined oil, can solve the problems of high cost, easy pollution, poor safety and reliability of storage tanks, and achieve high safety and reliability. Small impact on the environment and improved overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

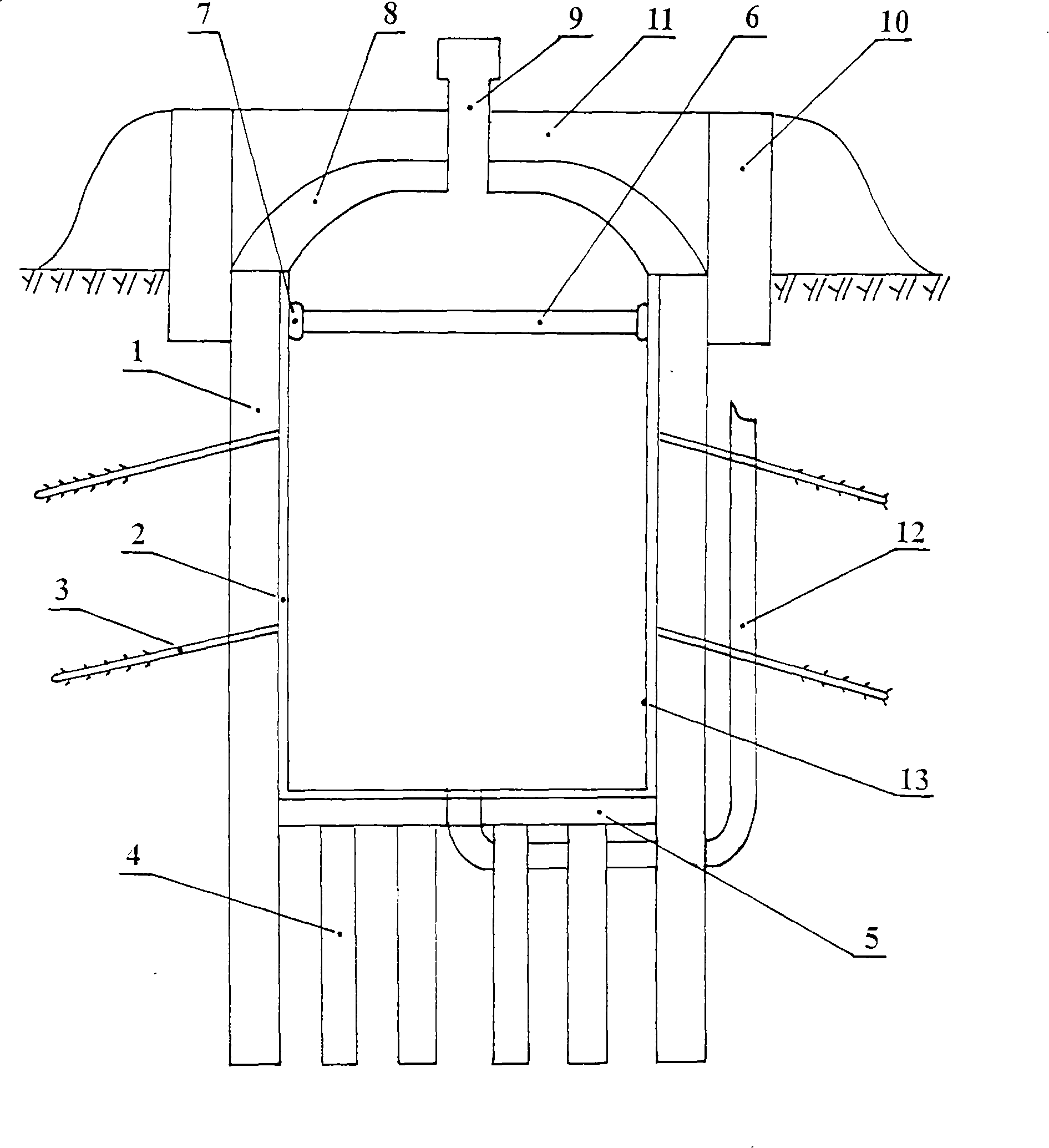

[0010] Referring to the accompanying drawings, the large-capacity underground oil storage depot is all built underground, and the storage body is a cylinder. The storage body consists of a curtain pile or an underground diaphragm wall, concrete 1 and a steel plate layer 2 to form an integral structure, and is anchored by an anchor rod 3 connected to the steel plate layer 2 . The bottom of the storage body is composed of a pile foundation 4, a reinforced concrete bottom plate 5 and a steel plate layer 2. The upper part of the storage body is an inner floating roof structure 6, and an elastic seal 7 is installed around the floating plate of the inner floating roof structure 6, which can float up and down along the inner wall of the storage body; the top of the storage body is closed by a prestressed dome structure 8 and A vent pipe 9 is installed, and a breathing valve and a flame arrester are installed on the vent pipe 9. A fire wall 10 is built around the ground of the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com