Method for preparing condensing multi-kernel aromatic resin carbon based solid acid catalyst

A carbon-based solid acid and aromatic resin technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve problems such as high price and thermal instability , to achieve the effect of low cost, good catalytic effect and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

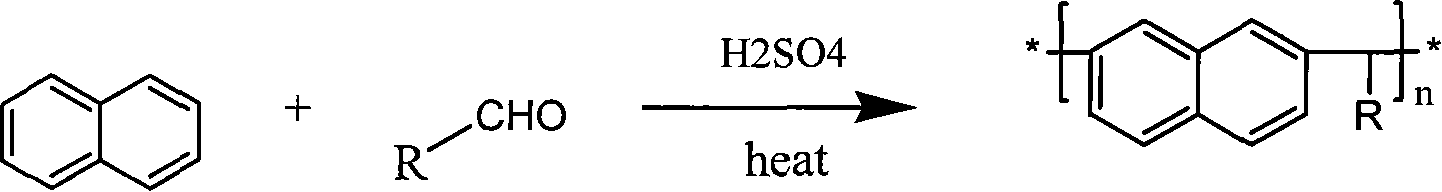

[0027] The first step is to prepare B-stage condensation polynuclear aromatic resin

[0028] Add: 0.1mol naphthalene, 0.5mol paraformaldehyde, 0.1g sulfuric acid to a 100mL three-neck flask equipped with electromagnetic stirring, thermometer, reflux condenser, and water separator, heat and stir, and carry out condensation reaction at 150°C for 24h to obtain Black goo.

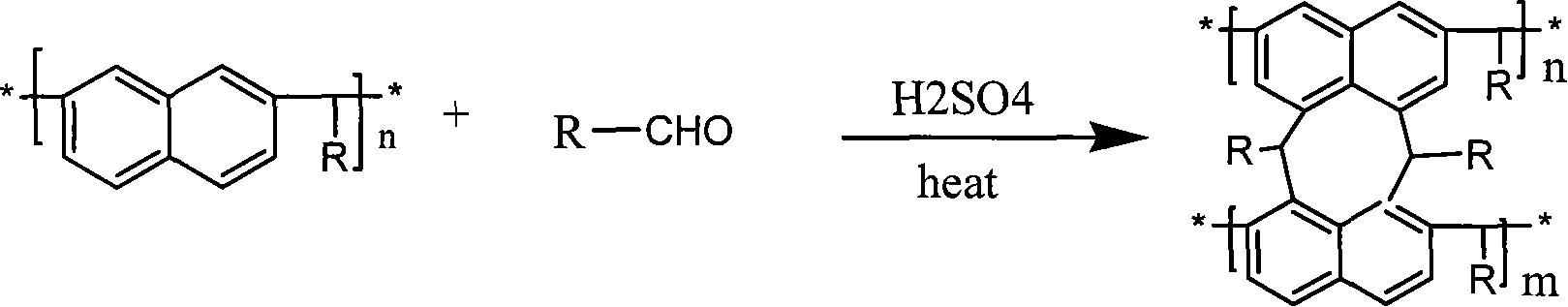

[0029] The second step is to prepare C-stage condensation polynuclear aromatic resin

[0030] Add 0.5 g of sulfuric acid to the viscous material obtained above, heat 0.1 mol of paraformaldehyde to 250°C, and perform a curing reaction for 16 hours;

[0031] Step 3 Wash, filter and dry

[0032] Cool the C-stage condensation polynuclear aromatic resin obtained above to room temperature, add hot water at 80°C to wash, and filter until the filtrate is clear and no sulfuric acid is detected, then place the product in an oven at 120°C, Dry for 1 day.

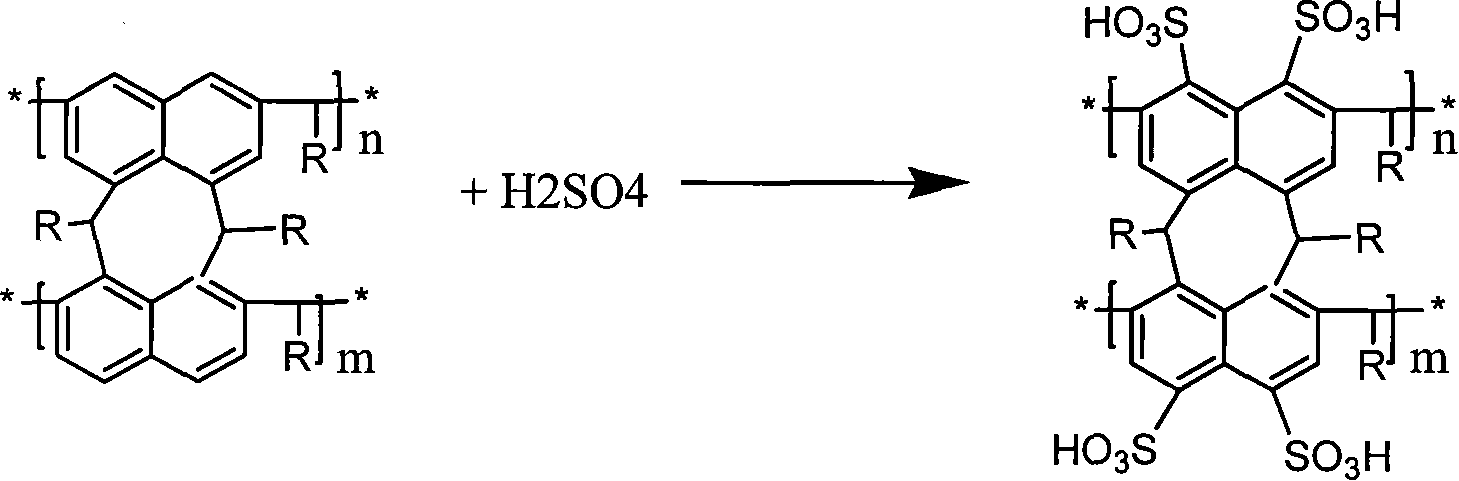

[0033] Step 4 Sulfonation reaction and washing with water and ...

Embodiment 2-4

[0036] Except following difference, all the other are identical with embodiment 1, and the ratio consumption of paraformaldehyde is by the ratio of table 1, and the results are shown in table 1

[0037] Table 1

[0038] Example

Embodiment 5-7

[0040] Except for the following differences, all the other are the same as in Example 1, and the sulfonation reaction time is provided in Table 2 respectively.

[0041] Table 2

[0042] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com