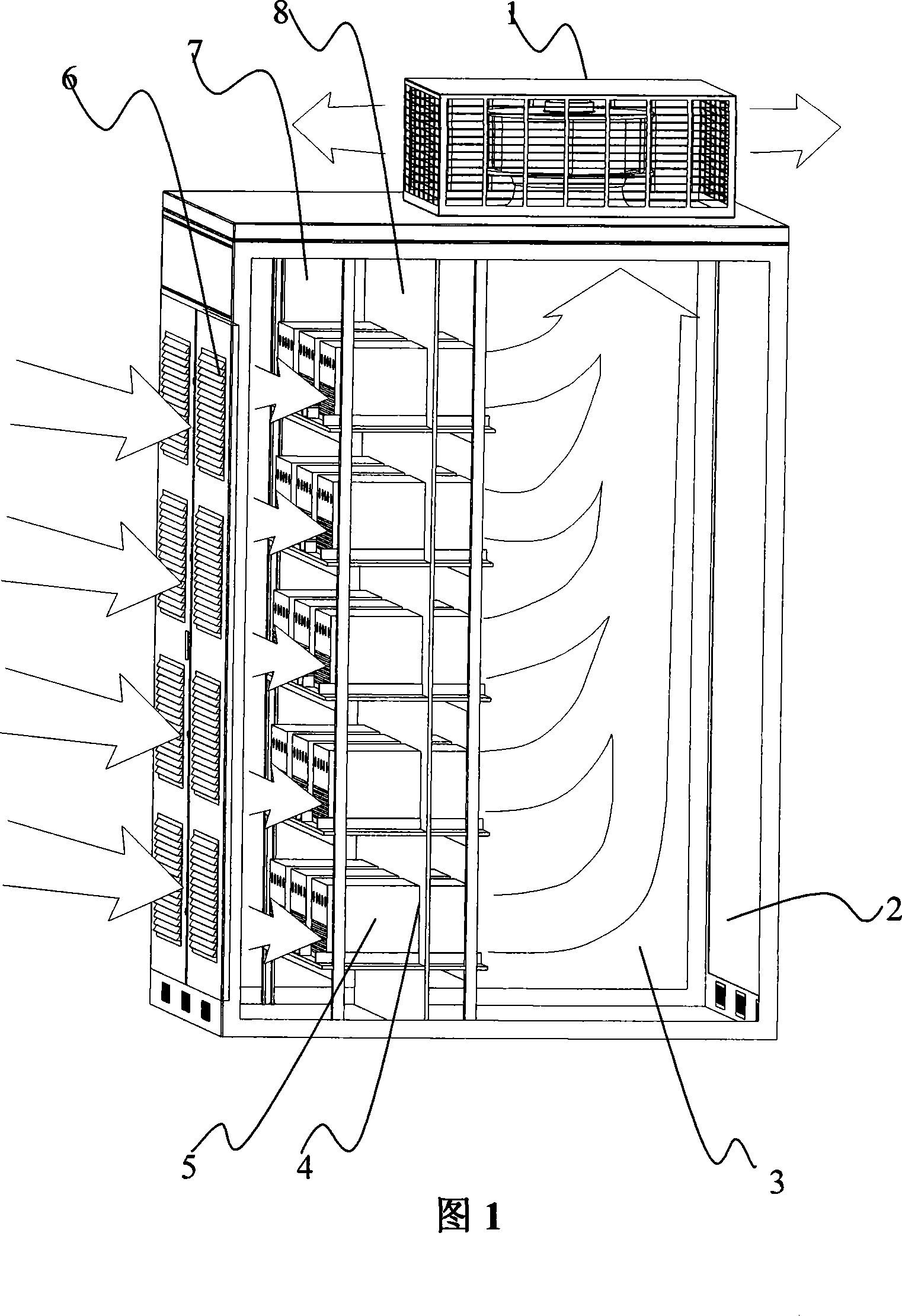

Heat radiation device for middle and high voltage high-power case frequency converter

A technology of heat dissipation device and frequency converter, applied in the direction of output power conversion device, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of high noise, high speed, large air volume, etc. The effect of uniform airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

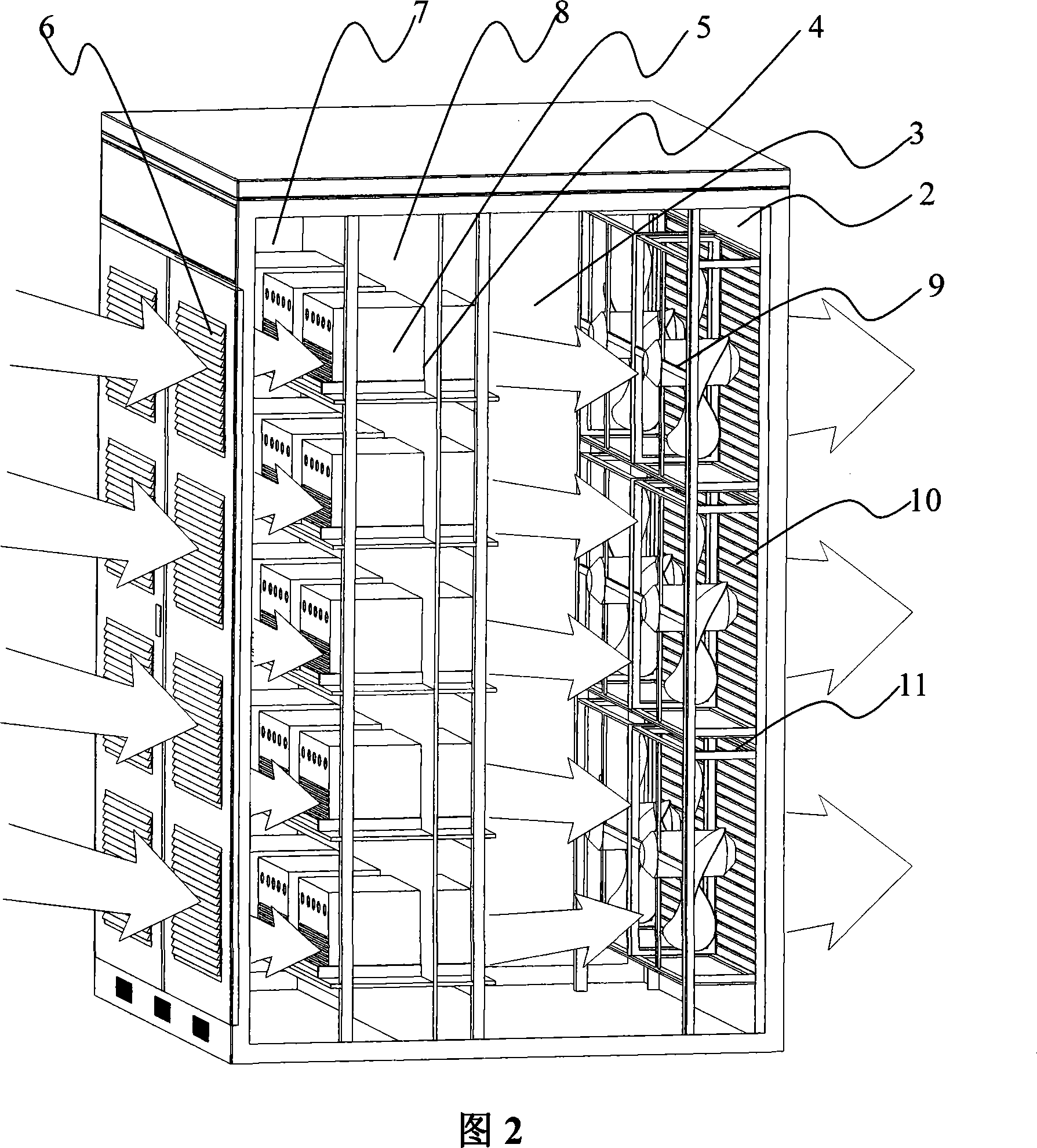

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0011] It can be seen from Fig. 2 that the present invention includes: cabinet rear plate 2, frequency converter rear air chamber 3, multiple windows 4 for ventilation and heat dissipation of the power unit, power unit 5, front air inlet 6, cabinet front air chamber 7, The air isolation board 8; also includes: at least one axial flow fan 9 inside the cabinet rear panel 2, a rear air outlet grid 10 on the cabinet rear panel 2, and an axial fan bracket 11;

[0012] The at least one axial flow fan 9 is six, and two columns are arranged sequentially from top to bottom;

[0013] The front air outlet 6, the air outlet of the air separation plate 8, the array of axial flow fans 9 and the rear air outlet grid 10 are located on the same straight line;

[0014] The air flow direction of the rear air outlet grid 10 is within 45° up and down of the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com