Photoetching system mask proximity effect correction method

A technology of proximity effect and lithography system, which is applied in optics, originals for photomechanical processing, instruments, etc., can solve the problems of graphic couplets and strong phase shift mask technology that cannot be applied, so as to improve graphic fidelity, The effect of precision control and imaging contrast enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

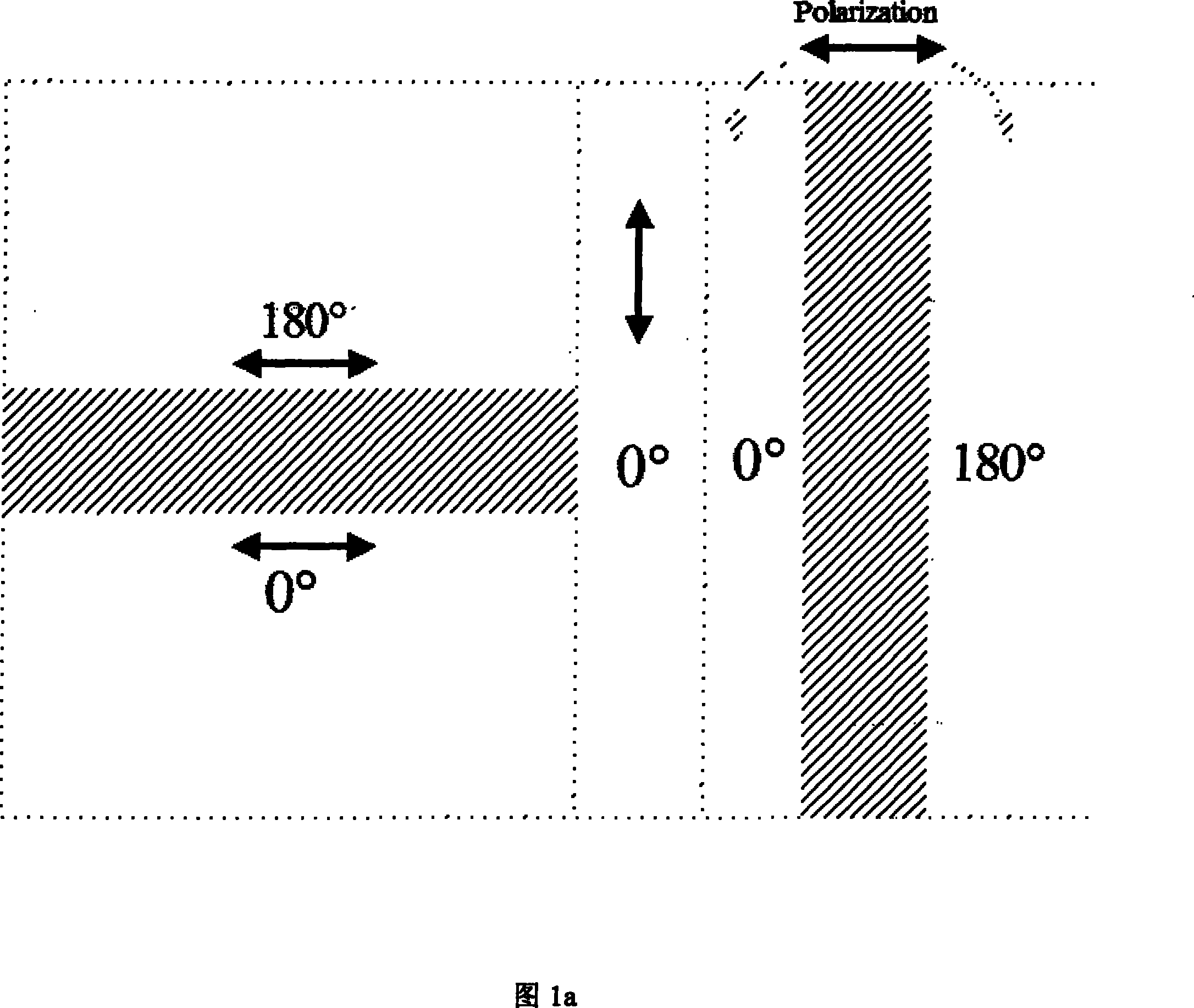

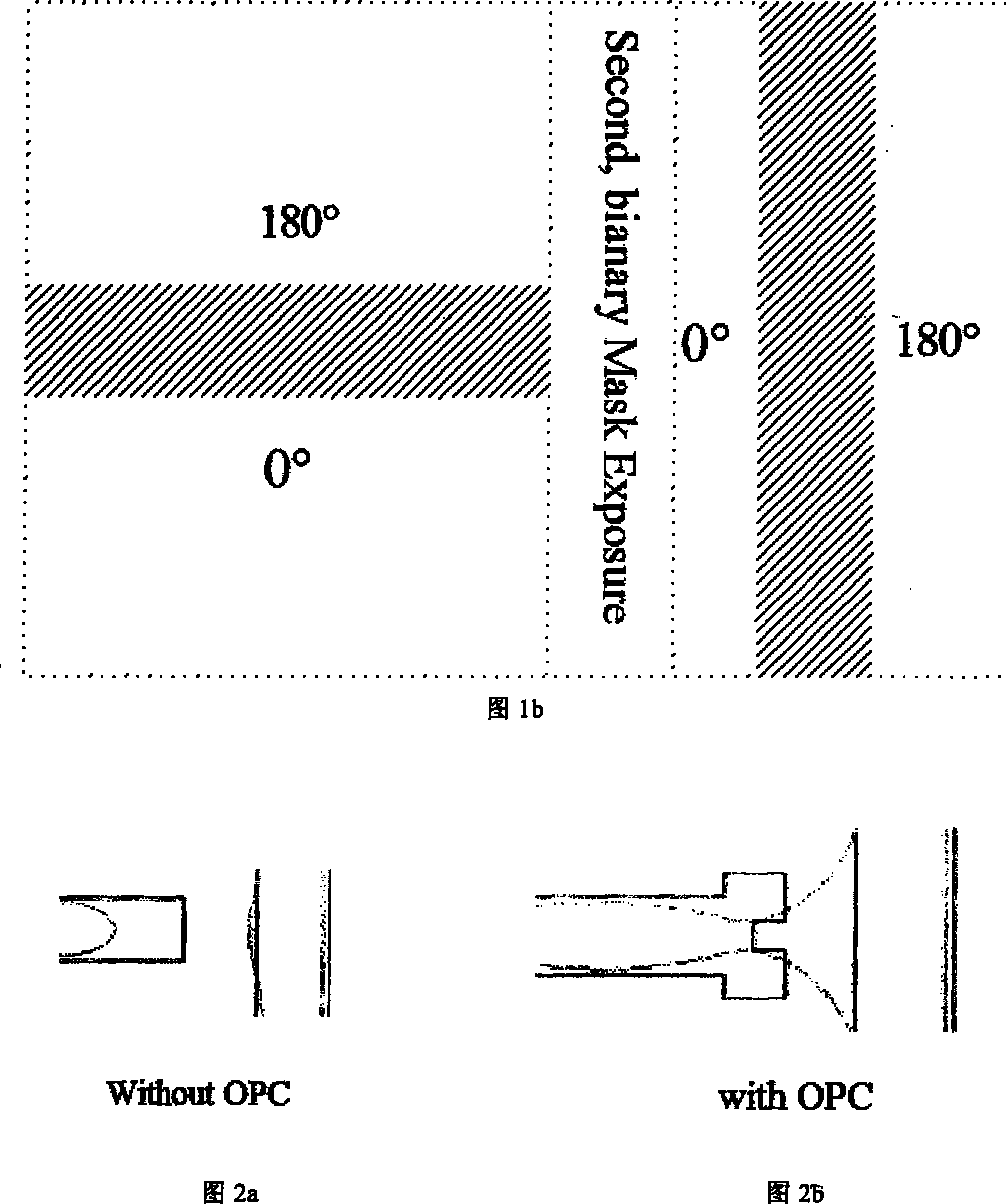

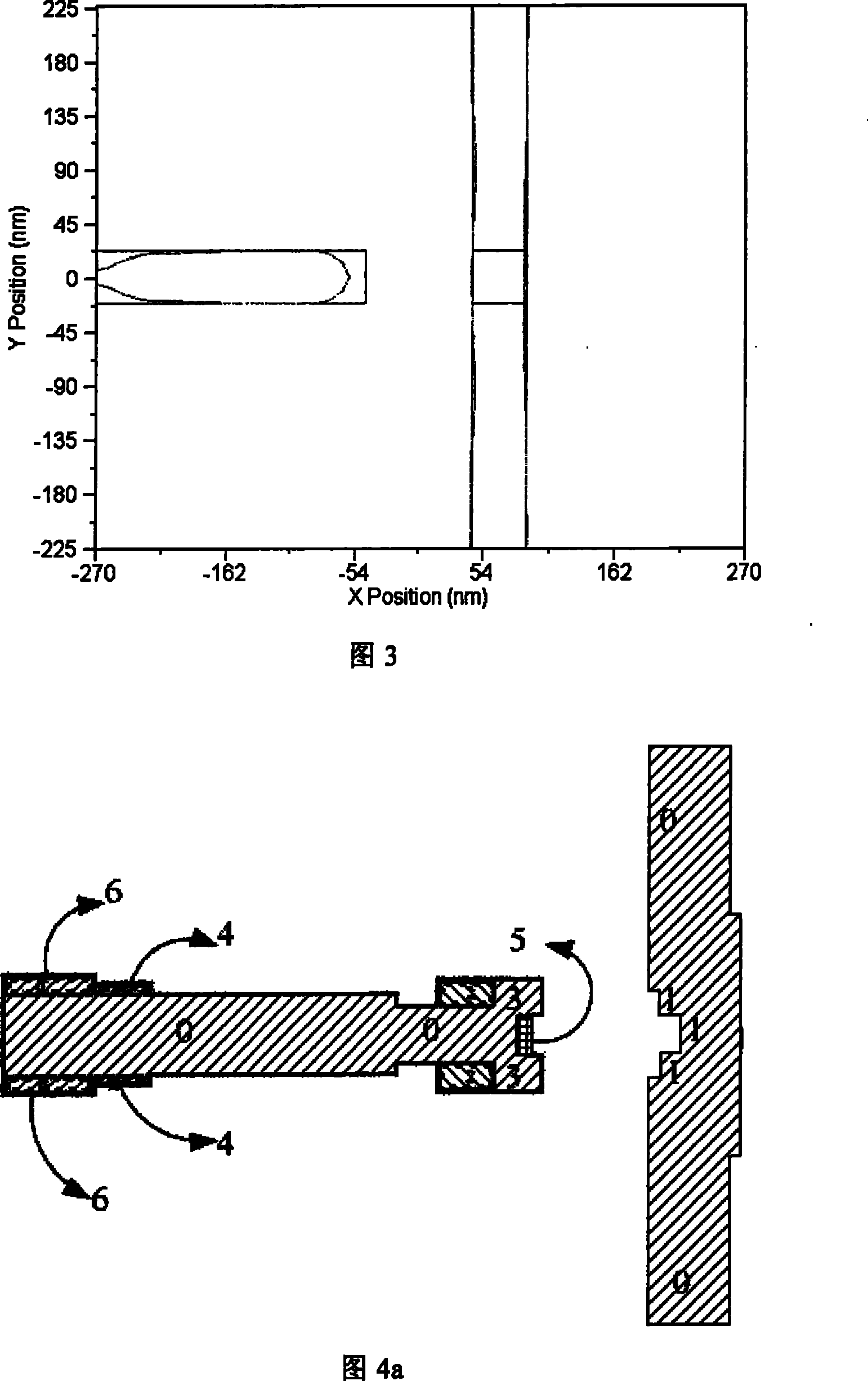

[0030] The specific operation steps of the correction method of the present invention are: first according to image 3 As shown in the original mask photolithography simulation exposure graphics results, it is judged that the part of the distortion that needs to be corrected by proximity effect; according to the position of the distorted graphics, at the corresponding position of the mask graphics, the proximity effect correction method is used to correct the mask graphics. Pre-segmentation and addition: At the junction of X and Y graphics, initially add serifs according to the method of phase-shift proximity effect correction, and add proximity effect correction with a certain transmittance and 180-degree phase shift on both sides of the serif Split graphics, preset as Figure 4a The phase-shift proximity effect correction shown, the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com