Acetic acid and acetic anhydride carbonyl reaction kettle for gas liquid ejecting combined slurry bed

An acetic anhydride carbonyl and combined technology, applied in the preparation of carboxylic anhydride, organic chemistry, etc., can solve the problem of affecting mass transfer between gas-liquid phase reaction medium and catalyst system, affecting system reaction conversion rate and selectivity, high production and operating costs, etc. problems, to achieve the effect of reasonable structure, improved stability, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

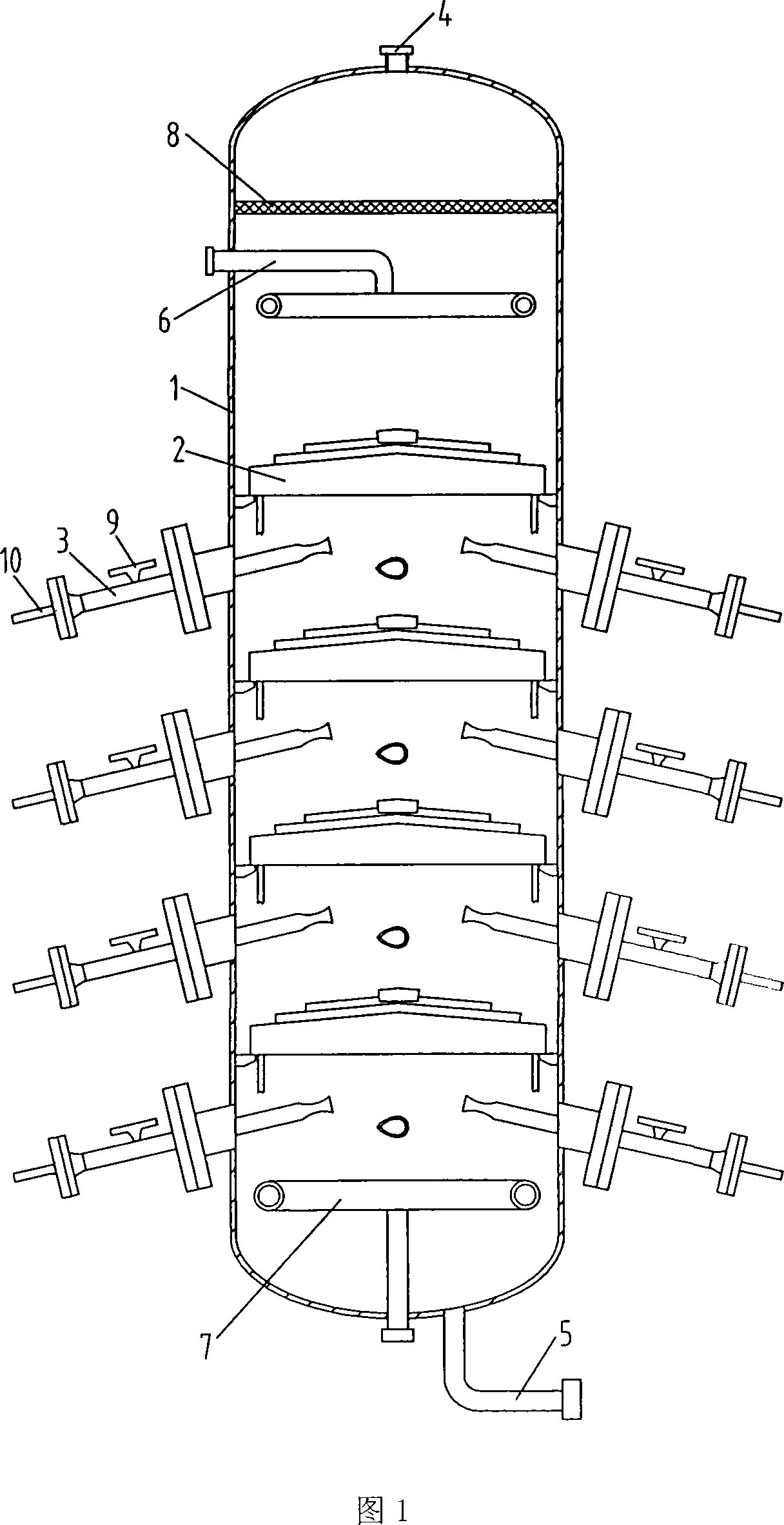

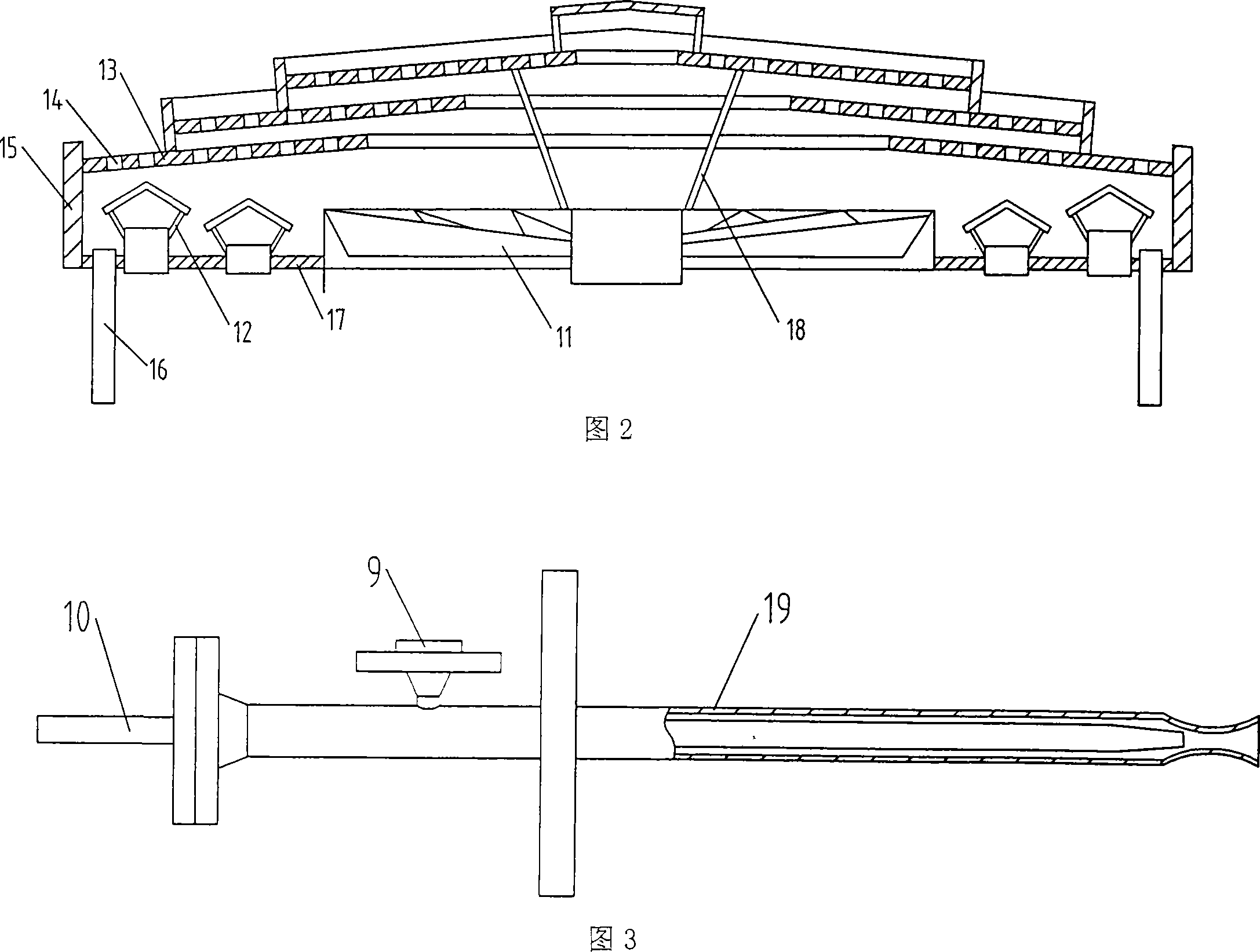

[0023] As shown in FIG. 1 , the reaction kettle of the present invention mainly includes a kettle body 1 , a fixed tray 2 and a gas-phase material injection pipe 3 . The top of the kettle body 1 is provided with a gas phase outlet 4, and the bottom of the kettle body 1 is provided with a liquid phase outlet 5. A liquid phase distribution pipe 6 is provided on the inner upper part of the kettle body 1 , and a gas phase distribution pipe 7 is arranged on the inner lower part of the kettle body 1 . The top of the kettle body is also provided with a defoaming net 8. Four fixed trays 2 are installed between the liquid phase distribution pipe 6 and the gas phase distribution pipe 7, and the bottom of each fixed tray 2 is provided with four gas phase material injection pipes 3 extending from the outside into the still body 1, each gas phase The material injection pipes are distributed at a certain angle along the radial direction, and each gas phase material injection pipe 3 is incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com