Method for preparing hydrogen and nitrogen by catalytic cracking regenerative fume

A technology for regenerating flue gas and catalytic cracking, applied in chemical instruments and methods, nitrogen preparation, separation methods, etc., can solve the problem of insufficient coking capacity of catalytic cracking unit regenerator, limitation of hydrogen production rate per unit carbon deposition of catalyst, flue gas Insufficient recovery of pressure, etc., to achieve the effect of being beneficial to active protection, reducing coke and dry gas yields, and reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

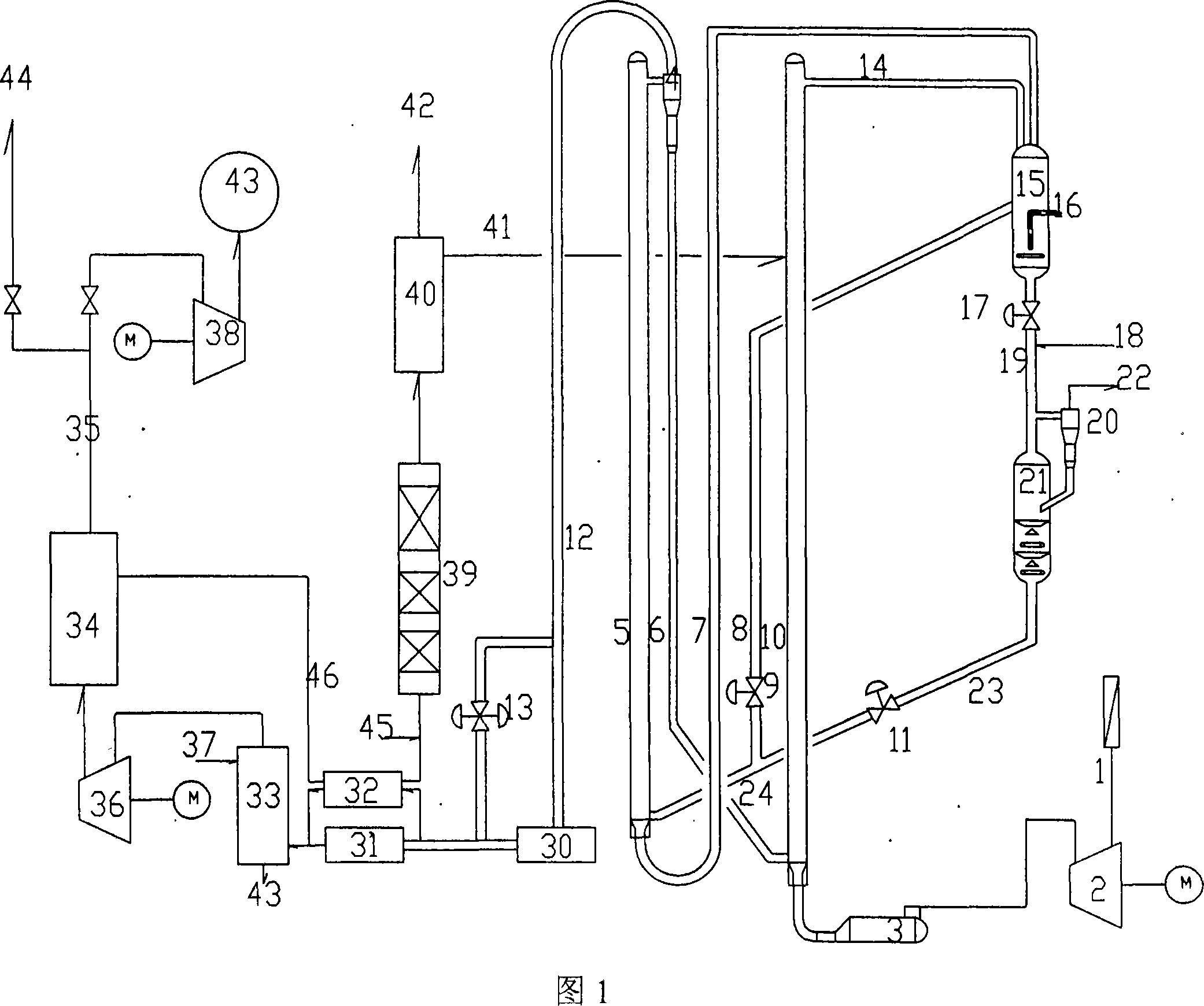

[0039] Embodiment 1: Below in conjunction with Fig. 1, elaborate on the first kind of technical solution of the present invention:

[0040] The charred main air 1 is pressurized by the main air blower 2 and enters the start-up auxiliary heating furnace 3, contacts and burns with the high-temperature semi-regenerated agent from the first regenerator 5 cyclone separator group 4 material legs 6 at the bottom of the second regenerator 10, CO from decarbonization system 40 2 It enters the middle and upper part of the second regenerator through the pipeline 41, and enters the catalyst high-level storage tank 15 through the inverted L pipeline 14 at the top of the second regenerator to realize the separation of the regenerated oxygen-containing flue gas and the regenerant.

[0041] The regenerated agent passes through the regeneration slide valve 17 to the downstream tubular reactor 19 to react with the atomized raw material oil 18, and realizes the separation of the reaction oil gas...

Embodiment 2

[0055] Embodiment 2: Below in conjunction with Fig. 2, elaborate on the second technical solution of the present invention:

[0056] In Fig. 2, the second regenerator and the catalyst high storage tank in Fig. 1 are replaced with the second regenerator 10, the downcomer reactor in Fig. 1 is replaced with a flexible riser 19, 26 is a lifting medium, and 28 is Refined oil slurry, 25 is the regenerated catalyst pipeline, and others are basically the same as in Fig. 1.

[0057] If the original catalytic cracking unit has a bed regenerator, this bed regenerator can be used as the second regenerator 10, and a tubular regenerator is added as the first regenerator 5; in order to reduce thermal cracking reactions, the original Reaction and settler part to be modified. Scorched main air 1 is pressurized to 0.3-0.45 MPa (absolute pressure) by main air blower 2 and then enters auxiliary heating furnace 3 for start-up, and the temperature of material leg 6 from first regenerator 5 cyclone...

Embodiment 3

[0061] Embodiment 3: Below in conjunction with Fig. 3, elaborate on the third technical solution of the present invention:

[0062] In Fig. 3, the flexible riser among Fig. 2 is replaced with riser reactor 19, the stripper among Fig. 2 is replaced with currently used settler 29, 20 is coarse cyclone separator, and 27 is primary cyclone Separator, others are basically the same as in Fig. 2.

[0063] If the original catalytic cracking unit has a bed regenerator, this bed regenerator can be used as the second regenerator 10, and a tubular regenerator is added as the first regenerator 5 in addition, and the original reaction and settler 29 parts are not Change. Scorched main air 1 is pressurized to 0.3-0.45 MPa (absolute pressure) by main air blower 2 and then enters auxiliary heating furnace 3 for start-up, and the temperature of material leg 6 from first regenerator 5 cyclone separator group 4 is 670-760°C Preferably, the high-temperature semi-regenerant at 690-730°C is contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com