Process and device for simulated moving bed seperation with a reduced number of valves

A technology for simulating moving beds and equipment, applied in the field of separation of natural or chemical products, and can solve problems such as special structure, large size, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

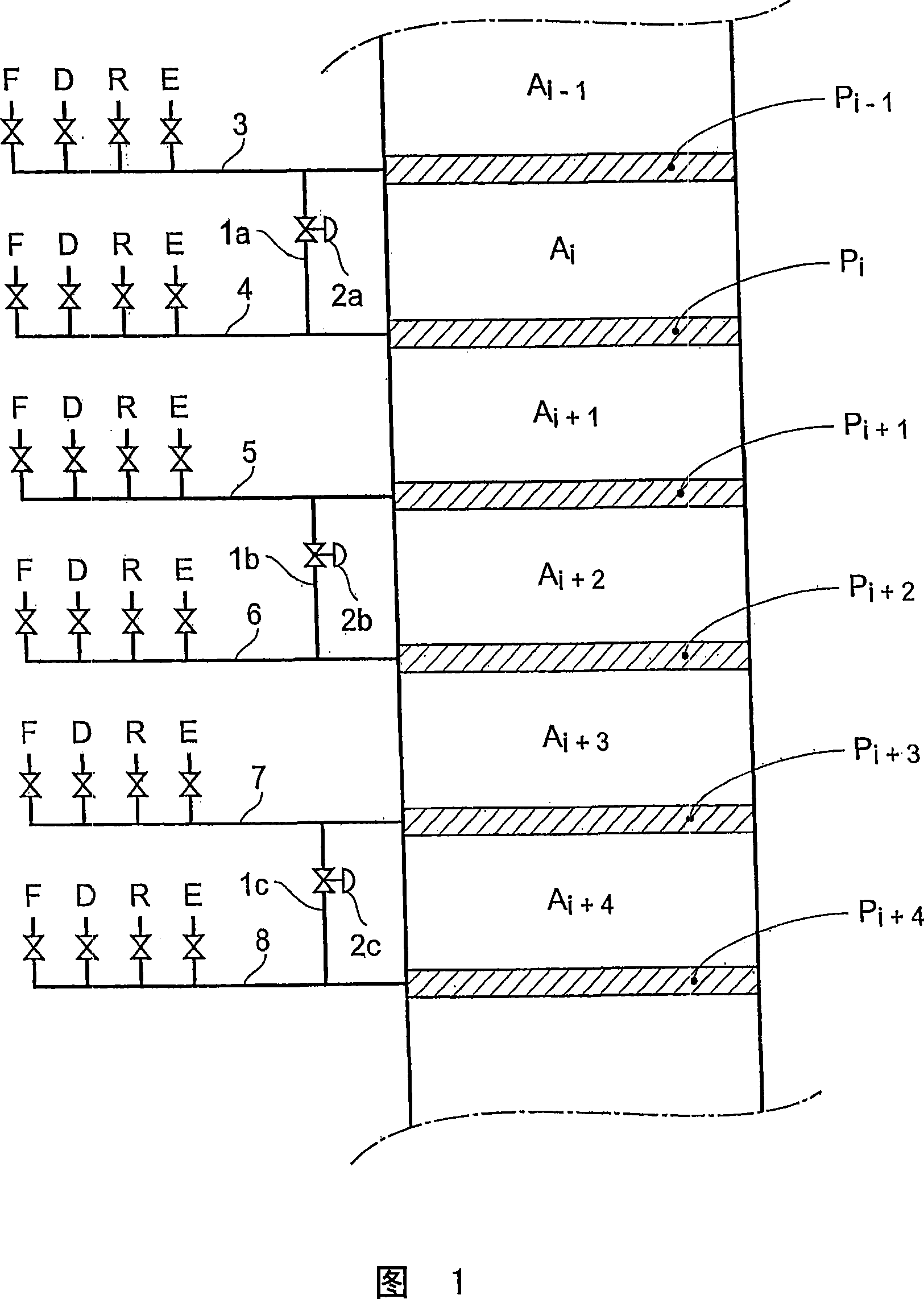

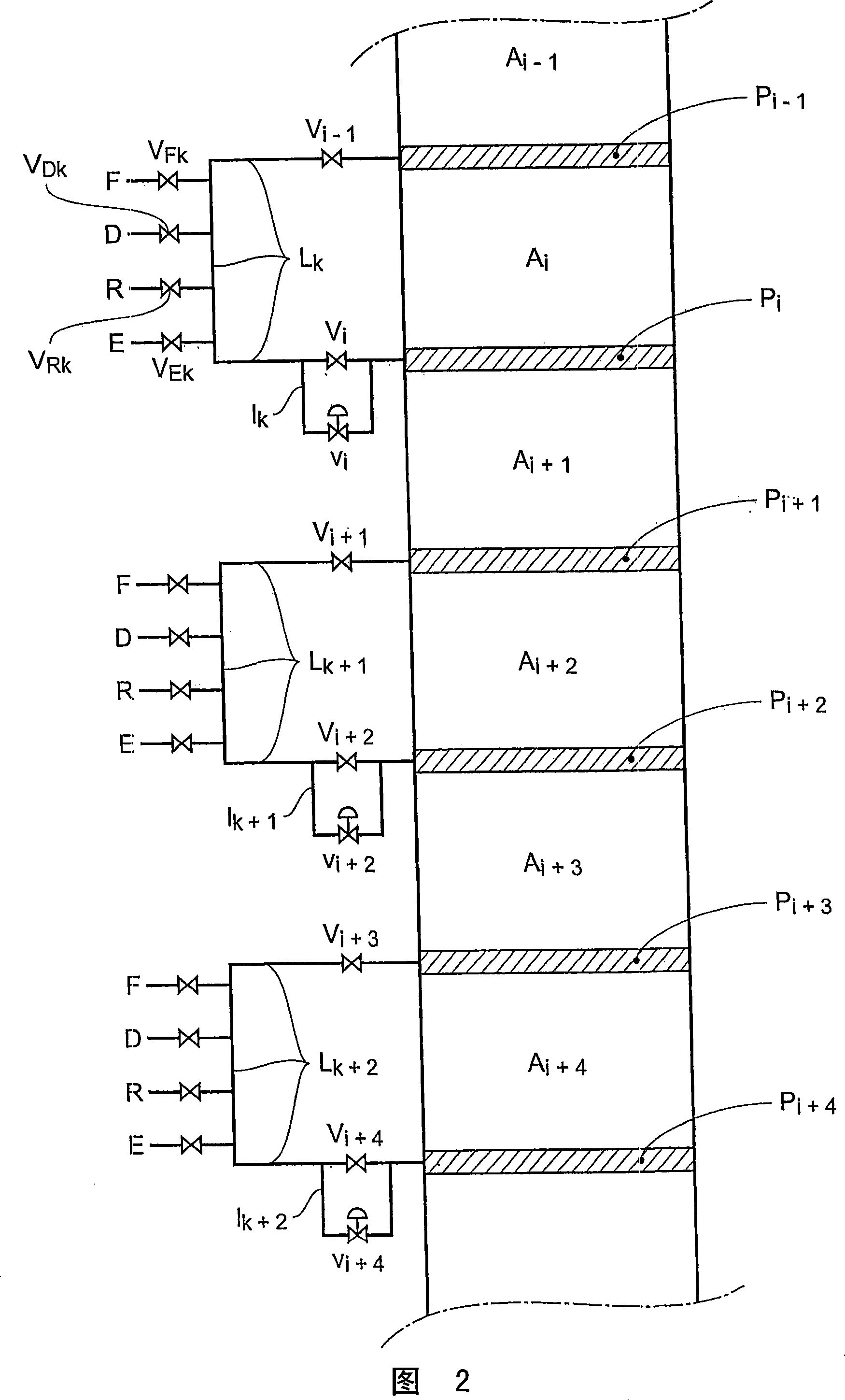

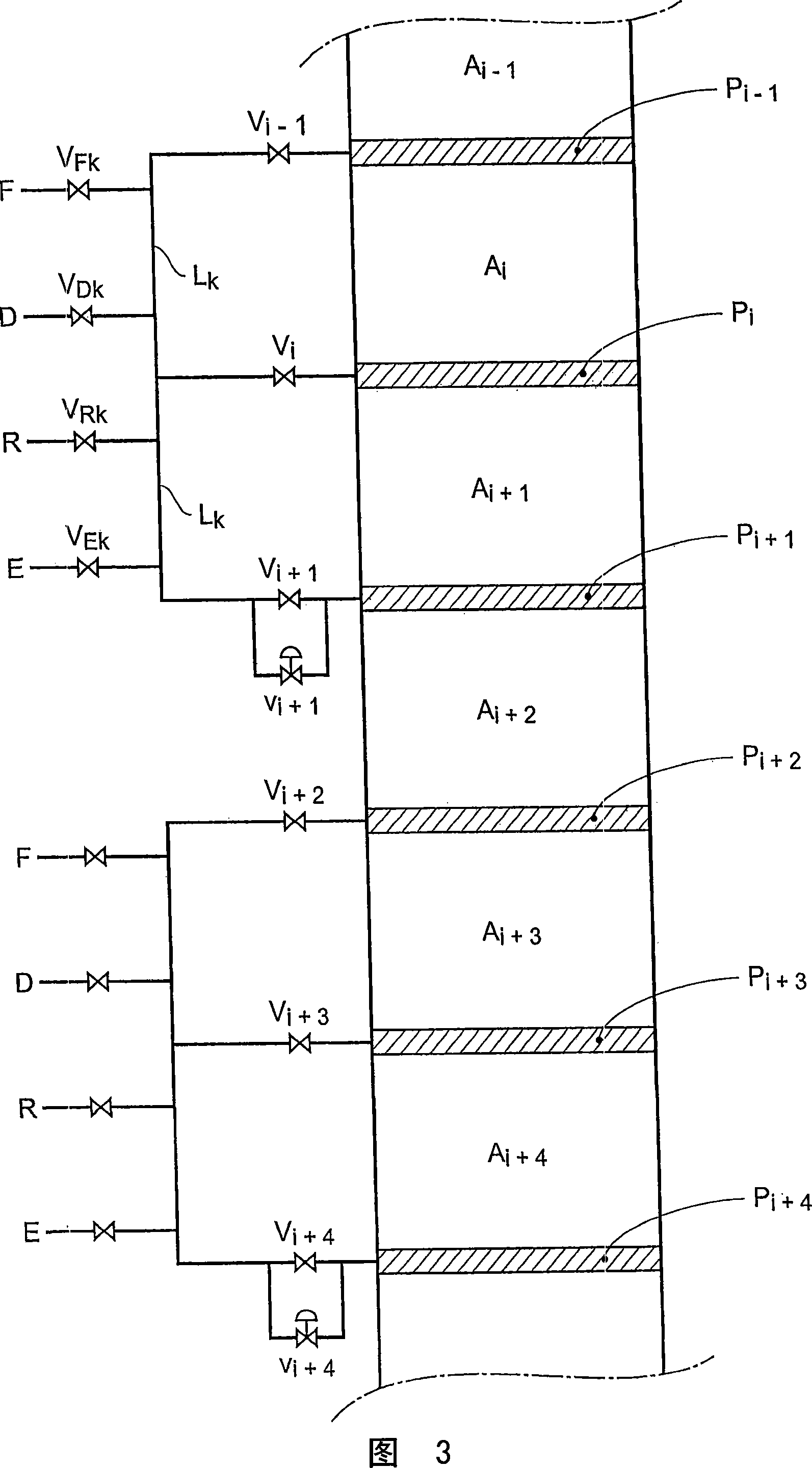

[0039] The invention will be better understood from the following description in conjunction with Fig. 1 (prior art), Fig. 2 and Fig. 3 (apparatus of the invention).

[0040] In order to achieve one of the above-mentioned objects, the present invention therefore proposes a device capable of separating at least one desired compound from a mixture containing such compound by adsorption in a simulated moving bed, comprising:

[0041] At least one column divided into a plurality of adsorbent beds Ai separated by distributor / extractor plates Pi to continuously supply and extract at least two feed fluids: feed F and desorbent D, and at least two withdrawal fluids : raffinate R and extract E, Pi placed between bed Ai and next bed Ai+1,

[0042] The equipment also includes at least one feed net F-net, desorbent net D-net, raffinate net R-net and extraction liquid net E-net, wherein each net is connected to the column by a plurality of intermediate pipelines, the The intermediate pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com