Light-transmitting electromagnetic shielding film, optical filter and plasma television

A technology of shielding film and electromagnetic wave, which is applied in the direction of AC plasma display panel, optical/shielding device, magnetic field/electric field shielding, etc. It can solve the problems of high cost, troublesome and complicated manufacturing process, etc., and achieve excellent conductivity and light transmission properties, Excellent electromagnetic wave shielding property, the effect of excellent electromagnetic wave shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

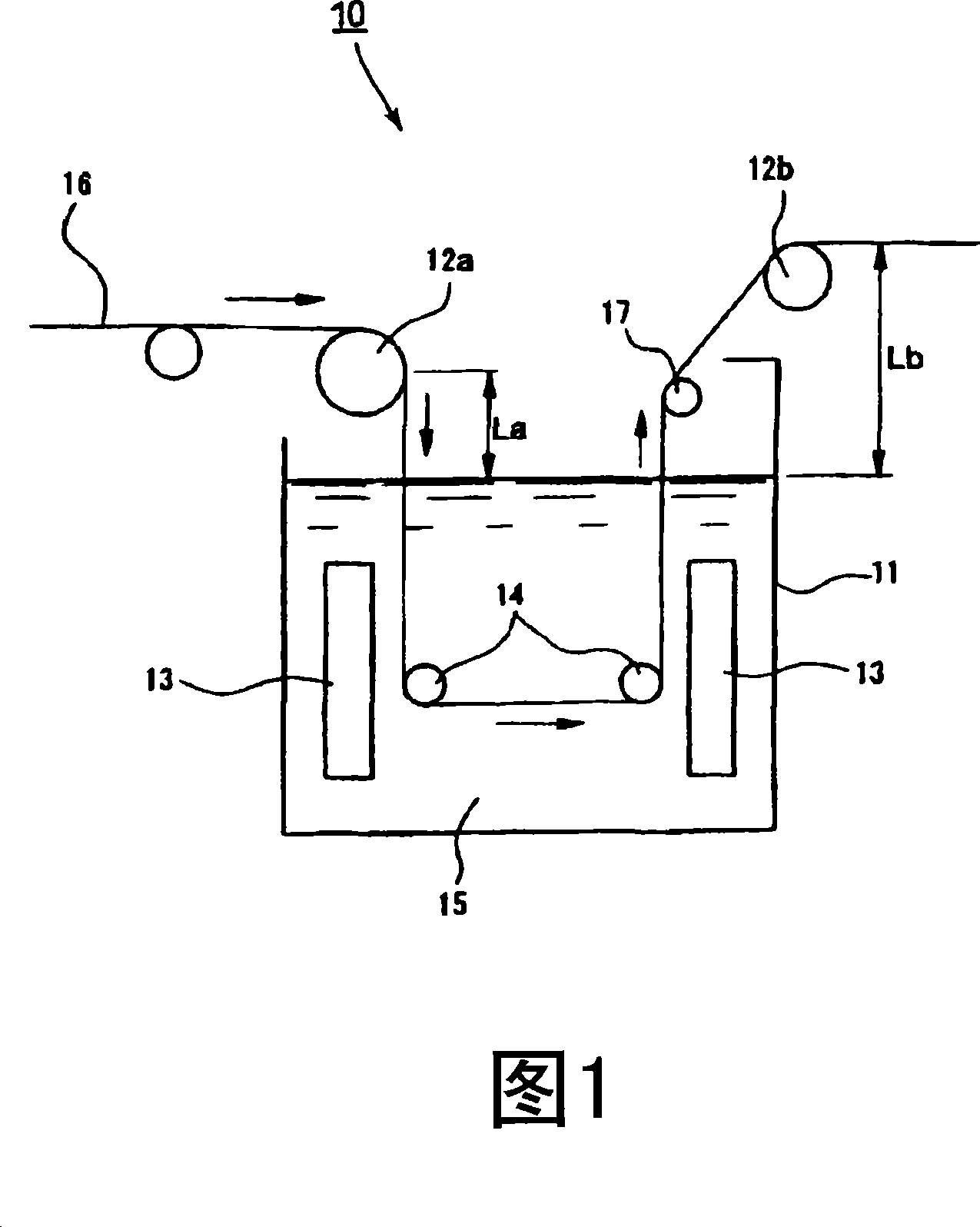

[0088] [Manufacturing method of light-transmitting electromagnetic wave shielding film]

[0089] The light-transmitting electromagnetic wave shielding film according to the present invention can be prepared by exposing a photosensitive material having a silver halide-containing emulsion layer on a support, and then performing a developing process to form metallic silver portions in the exposed area and the unexposed area, respectively. and light-transmitting parts, if desired, by applying a physical development and / or electroplating process to the metallic silver parts, thereby imparting conductive metal to the metallic silver parts.

[0090] The method of forming the light-transmitting electromagnetic wave-conducting film of the present invention includes the following two modes depending on the photosensitive material used and the developing process.

[0091] (I) A photosensitive silver halide monochrome photosensitive material without a physical development nucleus is subje...

Embodiment 1

[0381] [Preparation of near-infrared shielding film]

[0382] (Preparation of Composition for Shielding Near Infrared Rays)

[0383] Dissolved and mixed 2 parts by weight of IRG-022 (manufactured by NIPPON KAYAKU, melting point: 200°C) in a solvent mixture containing methyl ethyl ketone and toluene (mixing ratio by weight: 50:50), ie, N, N, N' , N'-tetra(p-diethylaminophenyl)-p-benzoquinone-two (immonium) hexafluoroantimonate, used as the diimonium compound of the first near-infrared absorbing dye, 1 weight part EXCOLOR810K ( Produced by NIPPON SHOKUBAI, the ratio of the absorption coefficient of the maximum absorption wavelength to the maximum absorption coefficient at 450 nm, 550 nm, and 620 nm is 10.2, 8.3, and 9.1), used as a phthalocyanine dye as the second near-infrared ray absorbing dye, and 100 Parts by weight of DIANAL BR-80 (manufactured by MITSUBISHI RAYON, glass transition temperature: 105° C.), to obtain a resin composition.

[0384] (Formation of near-infrared ...

Embodiment 2

[0444] (Preparation of optical filter)

[0445] A continuous film of Sample 1-1 as described above was treated with a copper blackening solution to blacken the copper surface. As the blackening solution, a commercially available product COPPER BLACK (manufactured by ISOLATEKAGAKU KENKYUSHO) was used.

[0446] The surface resistivity of this electromagnetic wave shielding film was 0.3Ω / □.

[0447] The visible light transmittance of this electromagnetic wave shielding film was 90%.

[0448] The light-transmitting electromagnetic wave shielding film thus obtained has electromagnetic wave shielding ability and near infrared ray shielding ability (light transmittance of 800-1000 nm rays: 15% or less) without causing practical problems. In addition, this membrane achieves both properties simultaneously in a single membrane.

[0449] The light transmittance was measured using a U-3500 type spectrophotometer (manufactured by HITACHI).

[0450] The resulting film had a metal mesh s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com