Hook structure

A shell and plate technology, applied in mechanical equipment, building structure, chassis/cabinet/drawer parts, etc., can solve problems such as difficulty, increased time required, cost, etc., to achieve protection from breakage, The effect of simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

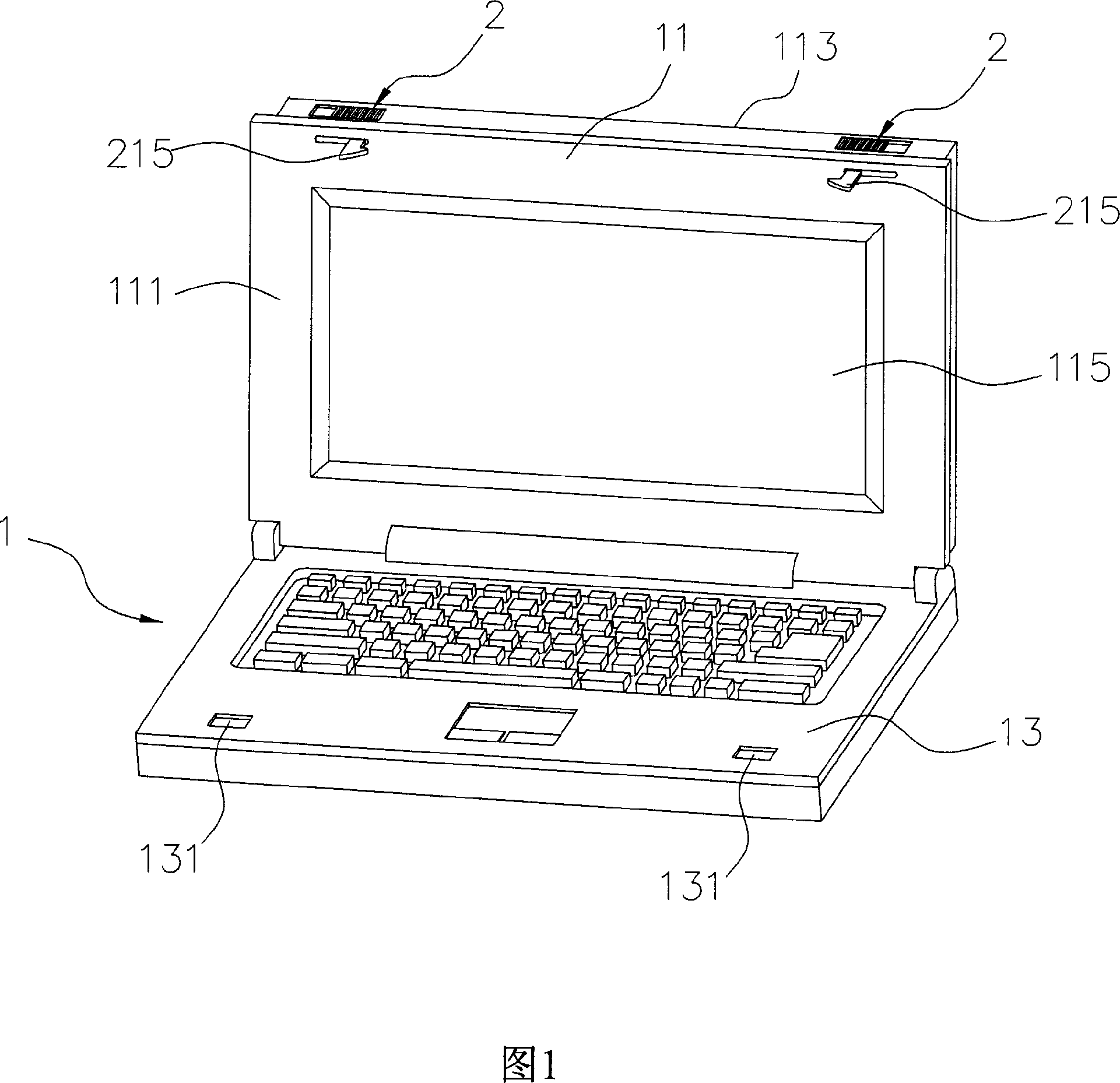

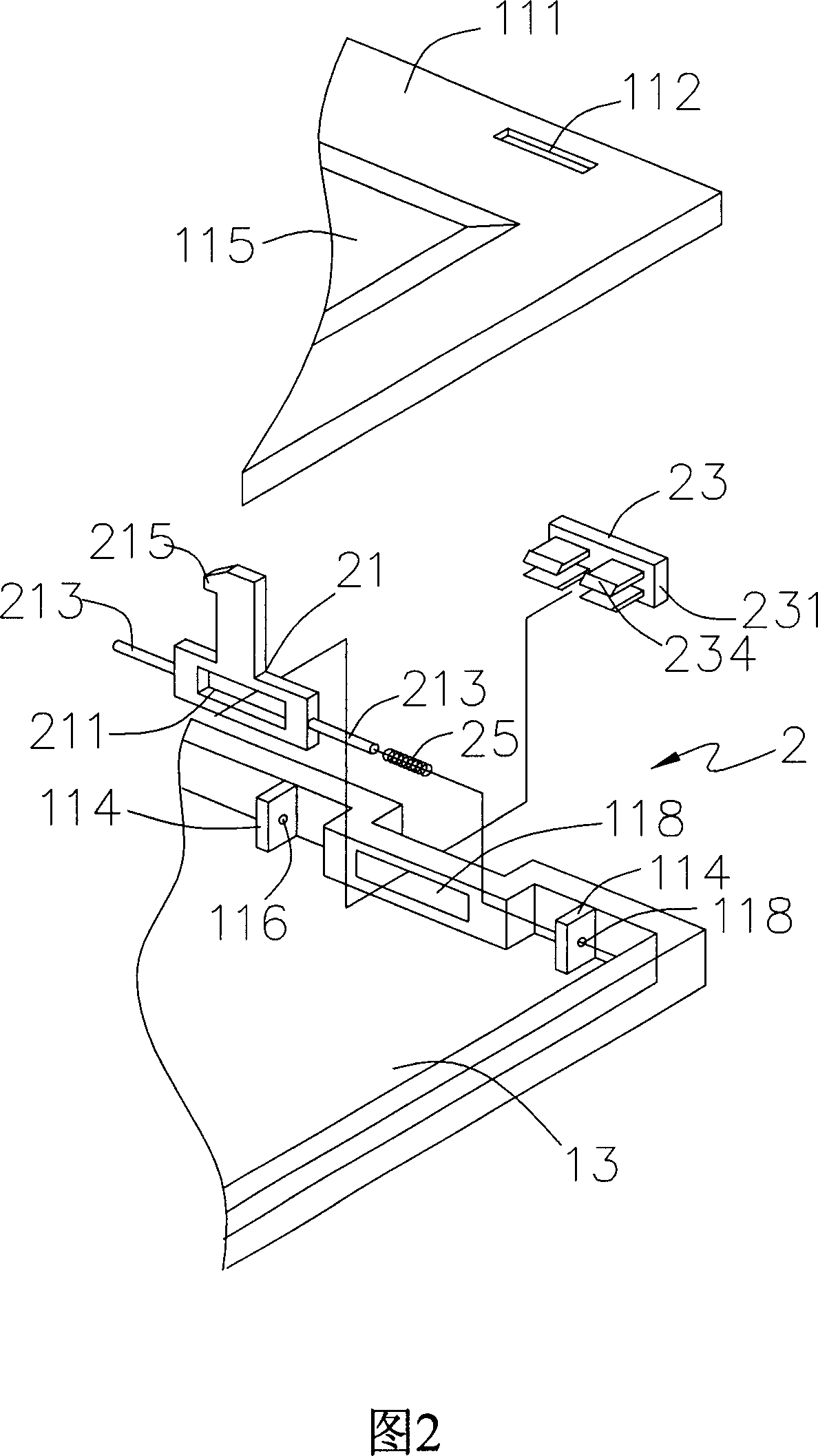

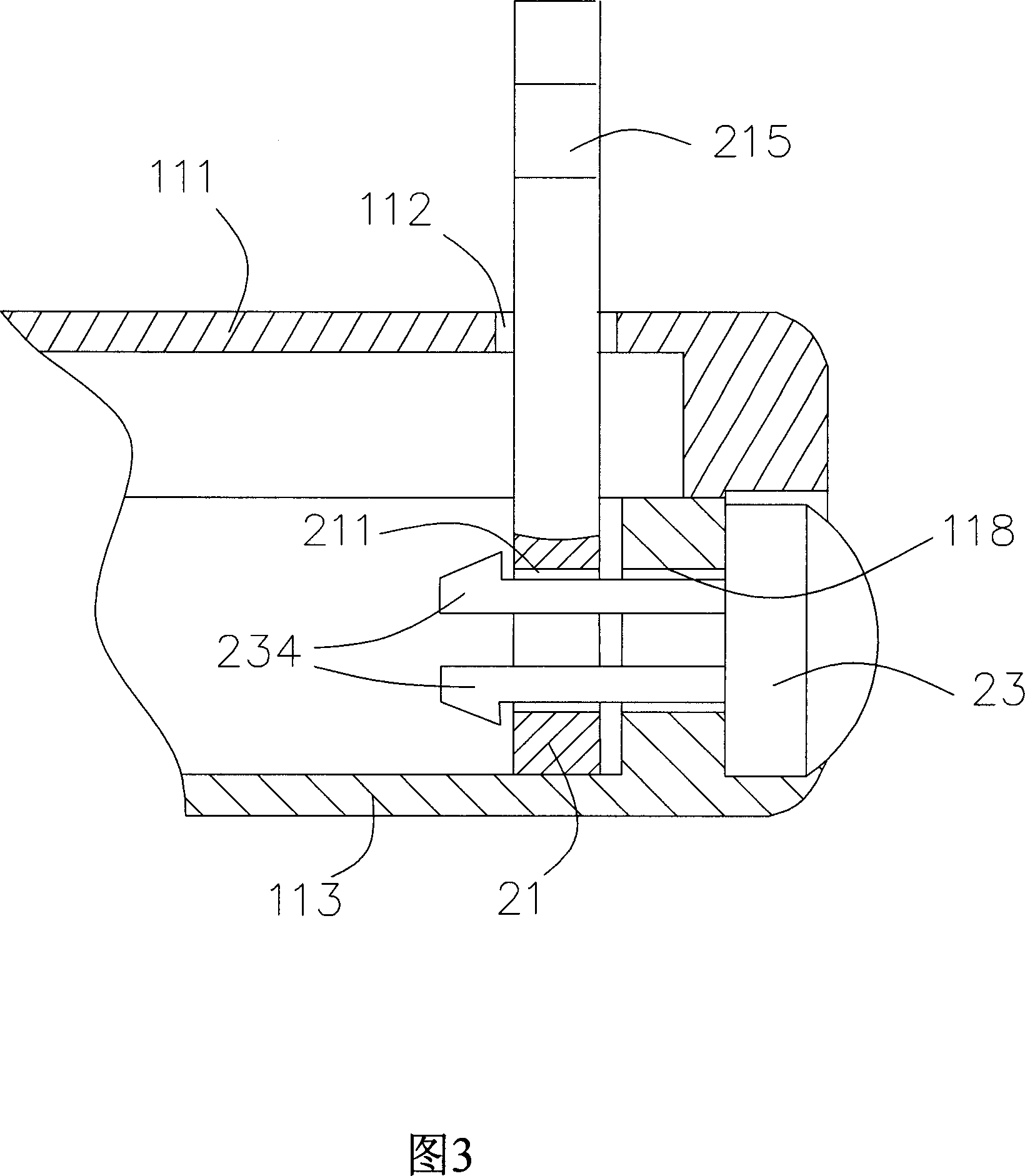

[0033] In order to make the above-mentioned purposes, features, and advantages of the present invention more obvious and easy to understand, the following preferred embodiments of the hook mechanism according to the present invention will be described in detail below in conjunction with the attached drawings, wherein the same elements Description will be made with the same reference numerals.

[0034] Please refer to FIG. 4 , which is a three-dimensional exploded schematic diagram showing the hook mechanism with integrally formed cushioning material of the present invention. In the figure, the hook mechanism 4 is suitable for the screen casing of a portable electronic device. The screen casing is composed of a front cover 31 and a rear cover (not shown in the figure), and the hook mechanism 4 It at least includes an integrally formed buffer material 41 , a hook body 42 , a pressing plate 43 and a plurality of fixing parts 44 . The buffer material 41 has a first through hole 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com