Lighting apparatus

A technology for lighting devices and camera devices, applied in lighting devices, lighting device parts, measuring devices, etc., can solve problems such as reduced detection accuracy, uneven brightness, and difficulty in eliminating color unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

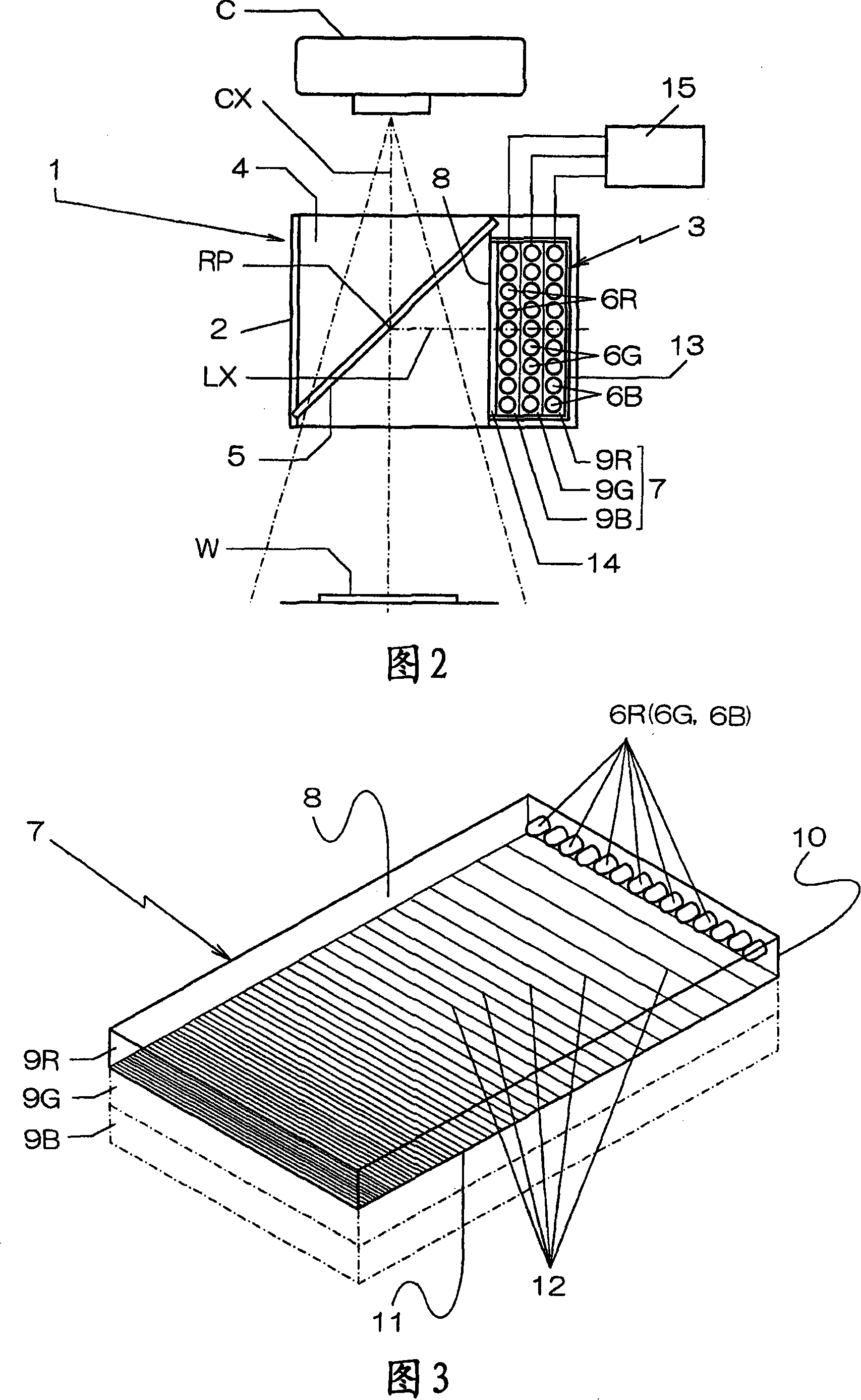

[0032] The illuminating device 1 shown in FIGS. 1 to 4 is arranged on the imaging optical axis CX from the imaging device C toward the subject W, and is used when illuminating the subject W with illumination light.

[0033] An LED light source device 3 is mounted on a cuboid body 2 to form the illuminating device 1 , and an imaging light-transmitting portion 4 through which an imaging optical axis X passes is formed on the body 2 .

[0034] Moreover, in the imaging light-transmitting part 4, the illumination optical axis LX and the imaging optical axis CX of the LED light source device 3 are intersected at a predetermined angle (in this example, a right angle), and the illumination light of the LED light source device 3 is arranged so that the illumination light of the LED light source device 3 is directed toward the object to be photographed. W reflects a half mirror (beam splitter) 5 so as to pass through this intersection point RP.

[0035] In addition, the LED light source...

Embodiment 2

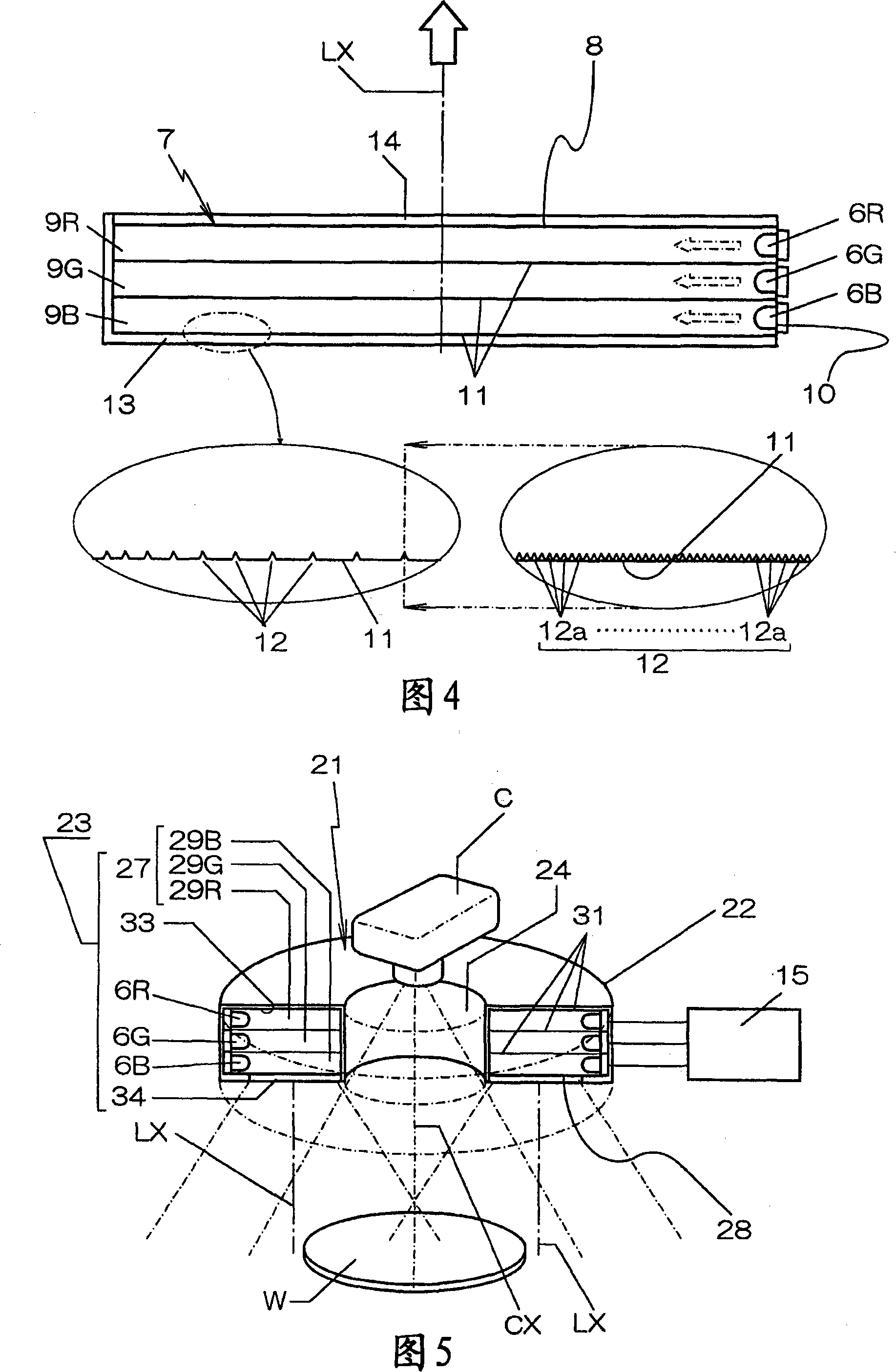

[0057] 5 and 6 show other embodiments of the lighting device of the present invention. In addition, the same code|symbol is attached|subjected to the part overlapping with FIGS. 1-4, and detailed description is abbreviate|omitted.

[0058] The body 22 of the illuminating device 21 of this example is formed into a ring that surrounds the imaging optical axis CX from the imaging device C to the subject W, and an LED light source device 23 is disposed on one side of the bottom surface thereof. 23 , so that illuminating light is irradiated from the bottom side of the body 22 , and the central part of the body 22 becomes the light-transmitting portion 24 for imaging.

[0059] This LED light source device 23 is diffused by the light guide body 27 from a variety of (in this example, RGB three primary colors) LED6R, 6G, and 6B irradiated light with different emission wavelengths. The direction of the illumination optical axis LX of the shooting object W irradiates its scattered light...

Embodiment 3

[0082] Furthermore, the body 22 or the light guide body 27 of the illuminating device 21 is not limited to a circular shape, and may be any annular polygon such as a circular triangle, a circular quadrangle, a circular hexagon, or a circular octagon, or may be a shape surrounding the imaging optical axis CX. Open circular ring or circular polygon formed by bending or bending like that.

[0083] For example, the body 42 of the illuminating device 41 shown in FIGS. The bottom side of the body 42 is irradiated with illumination light, and the central portion of the body becomes a light-transmitting portion for imaging.

[0084] This LED light source device 43 uses a light guide body 47 to scatter the light irradiated from various types of LEDs 6R, 6G, and 6B having different light emission wavelengths, and irradiates them along the direction of the illumination optical axis LX from the downward light emission surface 48 to the subject W. Scattered light.

[0085] In addition, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com