Glucoamylase produced by fermentation of wine lees miscible liquid and method for producing alcohol by fermenting restaurant garbage with this glucoamylase

A technology of food waste and mixed liquid, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of environmental pollution and high cost, and achieve the goals of avoiding pollution, reducing production costs, and improving glucoamylase activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: In this embodiment, the method for fermenting distiller's grains to produce glucoamylase is realized through the following steps: 1. Mix distiller's grains with water at a mass ratio of 1 to 2:1, and add 0.5 to 1.5 % (w / w), solid distiller's grains with a water content of 55-70%, to obtain a distiller's grains mixture; 2. Sterilize the distiller's grains mixture at 115-121°C for 15-20 minutes, and then add 6 ~10ml Aspergillus liquid, the proportion of spores inserted into the concentration of 1 × 10 7 ~3×10 7 Aspergillus per ml, shake the flask for 84-96 hours under the conditions of 30-35°C and 100-200r / min to ferment for 84-96 hours to obtain the saccharification enzyme liquid.

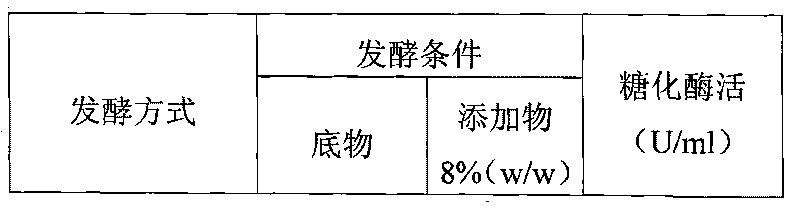

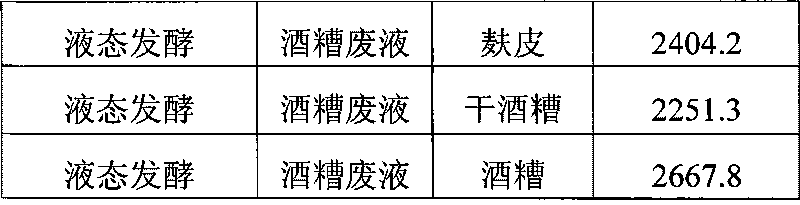

[0009] Comparative Experiment:

[0010] Mix distiller's grain waste liquid with water at a mass ratio of 1 to 2:1, add bran, distiller's grains (moisture content 70%) and dried distiller's grains respectively at a weight ratio of 0.8% of the mixture, wherein the bran ...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, 0.8-1.2% (w / w) solid distiller's grains with a water content of 58-67% are added to the mixed liquor. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, 1% (w / w) solid distiller's grains with a water content of 60% are added to the mixed liquor. Other steps are the same as in the specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com