Method for producing jujube clarification juice

A technology for clarified juice and jujube juice, which is applied in the production of clarified jujube juice and the production of clarified jujube juice by resin adsorption method, to achieve the effects of increasing light transmittance, simple production process, and strong jujube fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of Jujube Pulp

[0054] Wash the red dates, add 5 times the weight of the red dates in water, heat to 50°C in a jacketed pot, soak for 1 hour, then heat to 100°C, cook for 20 minutes, cool to 50°C, and then beat in a beating machine to make. The jujube pulp is obtained, and the mesh aperture of the beater is 1 mm.

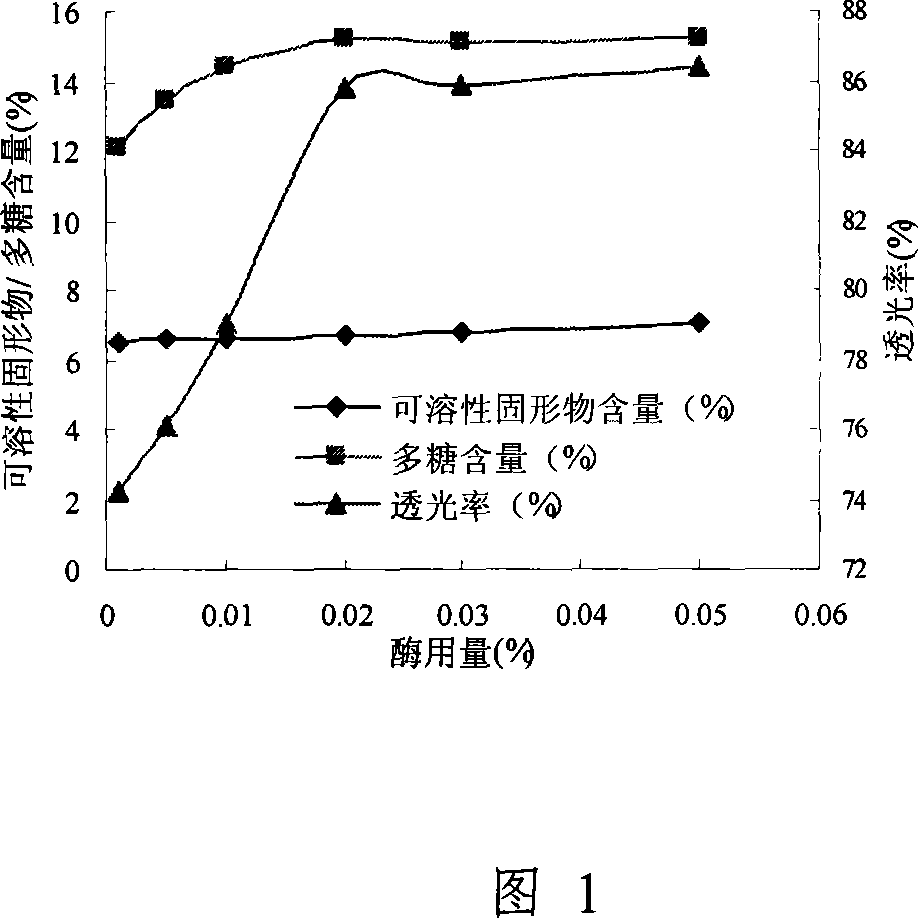

[0055] 2. Enzymatic hydrolysis

[0056] Put it in a jacketed pot, add 0.01% pectinase by weight of jujube juice, enzymolysis for 2 hours, and then squeeze the juice with a bag-type juicer to obtain 15% jujube juice.

[0057] 3. Chitosan Clarification

[0058] Put red date juice in a jacketed pot, add 3.0% chitosan solution by weight of red date juice under stirring (chitosan is dissolved with 1% citric acid solution to make 1% chitosan solution), 40 ° C Keep the temperature for 1 hour, when the bottom of the jacketed pot is precipitated, filter the juice with a 300-mesh sieve, and then use a centrifugal filter (7500 rpm) to remove the parti...

Embodiment 2

[0069] 1. Preparation of Jujube Pulp

[0070] Clean the red dates, add 3 times the weight of the red dates in water, heat them to 50°C in a jacketed pot, soak them for 1 hour, then heat them to 100°C, cook for 20 minutes, cool to 50°C, and then beat them in a beating machine to make them. The jujube pulp is obtained, and the mesh aperture of the beater is 1 mm.

[0071] 2. Enzymatic hydrolysis

[0072] The red jujube juice was placed in a jacketed pot, 0.05% pectinase was added, and enzymatic hydrolysis was carried out for 2 hours, and then the juice was squeezed with a bag-type juicer to obtain 16% jujube juice.

[0073] 3. Chitosan Clarification

[0074] The jujube juice prepared in step 2 is placed in a jacketed pot, and a chitosan solution of 6.0% by weight of jujube juice is added under stirring (chitosan is dissolved in a 1% citric acid solution in advance to make 1% chitosan. solution), kept at 40 °C for 1 hour, and when there was precipitation at the bottom of the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com