Optical fiber dissolved oxygen sensing head and preparing method thereof

A sensor head and dissolved oxygen technology, which is applied in the direction of material analysis, instruments, and measuring devices through optical means, can solve the problems of single shape of the sensor head, few fluorescent signals, and low coupling efficiency, so as not to be easily disturbed by the external environment , low price, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment.

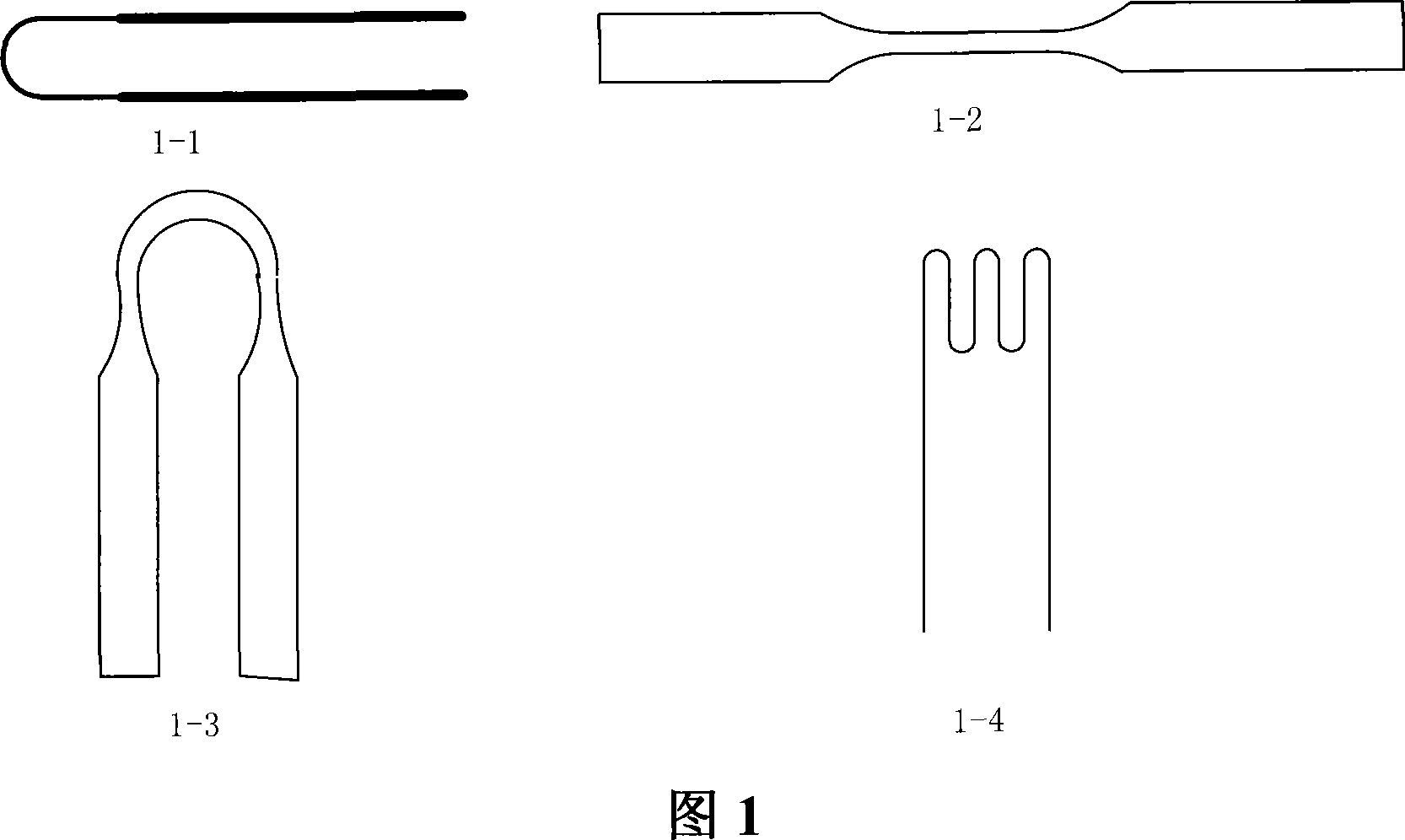

[0038] First please refer to Fig. 1, Fig. 1 is the structural representation of the optical fiber dissolved oxygen sensing head of the present invention, as can be seen from the figure, the structure of the optical fiber dissolved oxygen sensing head of the present invention is made of plastic optical fiber, and the shape of the sensing head has U Shape, biconical, biconical + U-shaped and filament-shaped, respectively see Figure 1-1, 1-2, 1-3, 1-4, the outer wall of the optical fiber of the sensing head is coated with sensitive materials.

[0039] The plastic optical fiber is polymethyl methacrylate plastic optical fiber.

[0040] The sensitive material is a sol-gel containing fluorescent substances.

[0041] The preparation methods of these optical fiber dissolved oxygen sensor heads are described respectively below.

[0042] The practice of U-shaped sensor head:

[0043] First ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com