Mixing delivery over-flow valve

An overflow valve, mixed transmission technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problem that the safety valve cannot stabilize the pressure, the pressure level is limited, and there is no overflow valve, so as to achieve stable working pressure, The effect of ensuring work safety and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

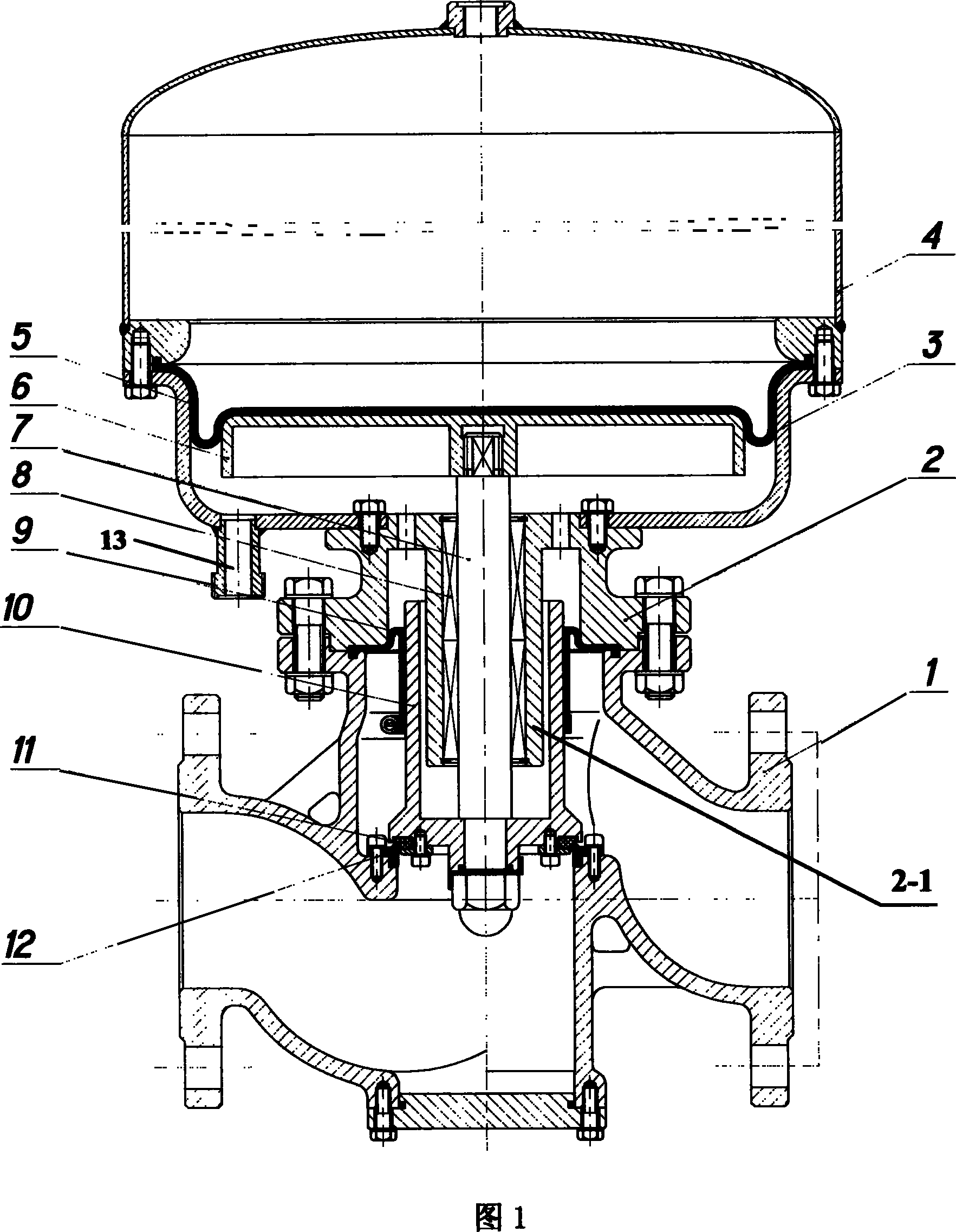

[0018] The mixed delivery relief valve includes a valve body 1, a valve seat 2, a valve core, and an air storage tank 4. The valve core includes a valve stem 7 and a valve core sleeve 10, and the lower ends of the two are fixedly connected; It is fixedly connected with the valve body 1, and the upper flange of the valve seat 2 is fixedly connected with the lower end of the gas storage tank 4 through the gas storage tank bracket 3; the middle part of the valve seat 2 is provided with a downwardly extending linear bearing sleeve 2-1, which passes through the linear bearing sleeve 2-1. The bearing 8 is socketed with the valve stem 7, the valve core sleeve 10 is socketed on the outer periphery of the bearing sleeve 2-1, the outer peripheral surface of the valve core sleeve 10 is fixedly socketed with a sealing diaphragm 9, and the upper end of the sealing diaphragm 9 is fixed around the valve body 1 and the flange end face of the valve seat 2, and between the lower end of the valve...

Embodiment 2

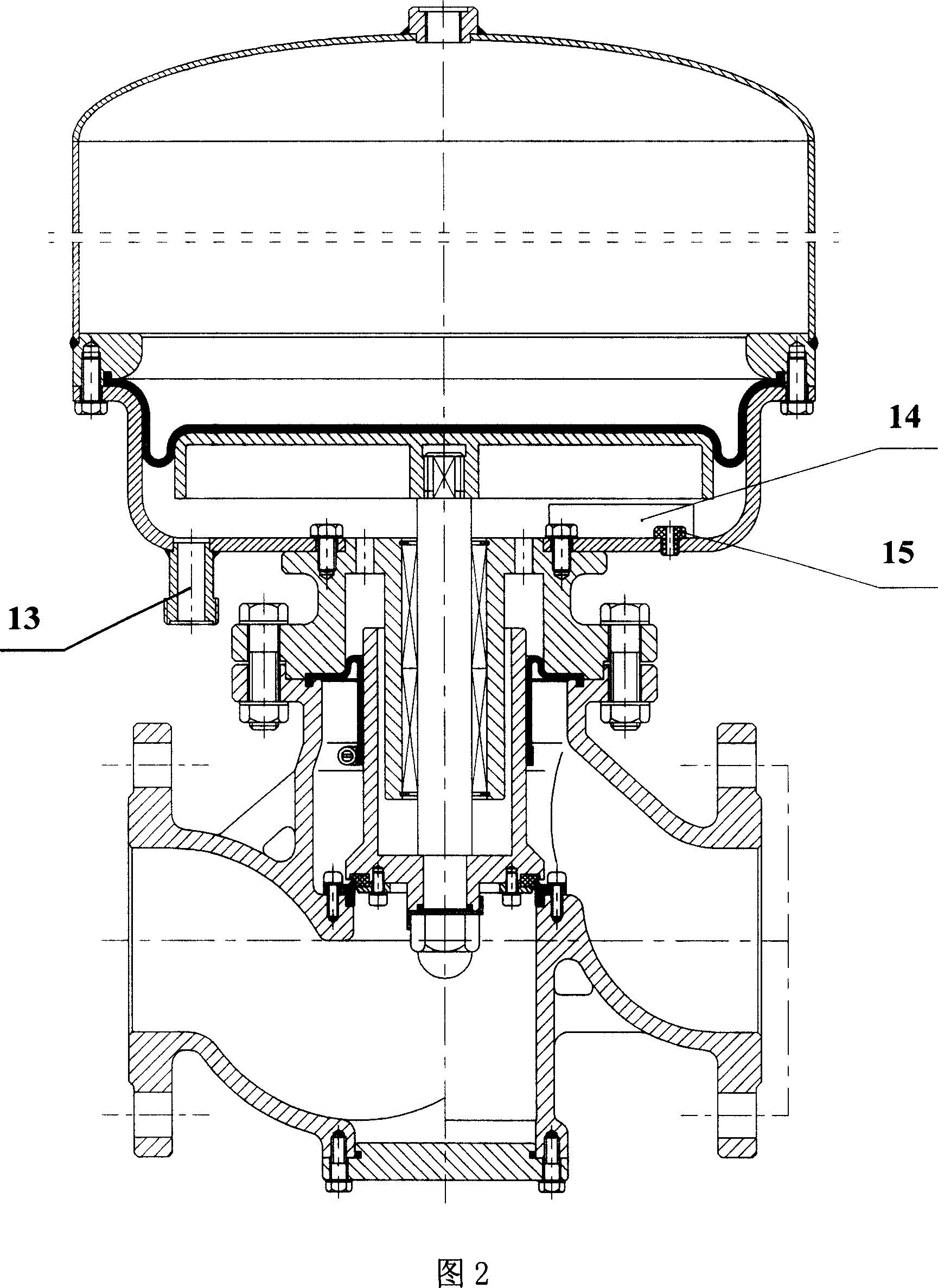

[0021] As shown in Figure 2, a sensor 14 is also provided in the air storage tank bracket 3 of the mixed transmission overflow valve, and its lead wire is connected with the remote controller through the lead wire joint 15 on the air storage tank bracket 3, and other structures are the same Example 1.

[0022] This mixed transmission overflow valve is an explosion-proof structure, suitable for highly toxic, highly corrosive, flammable, explosive or strong odor medium. Its working process is: when the system back pressure is too large and the sealing diaphragm 9 is damaged and leaks, The system is depressurized, the sensor 14 outputs an alarm signal, and the leakage medium is discharged from the emptying pipe 13 for safe treatment; other situations are the same as the common structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com