Internal-combustion engine starting method

A starting method and technology of internal combustion engines, applied to the starting of engines, motor vehicles, machines/engines, etc., can solve the problems of prolonging the starting stage, increasing fuel consumption, and not optimal air-fuel mixture, etc., to achieve improved starting performance, Reliable starting and the effect of reducing the target speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

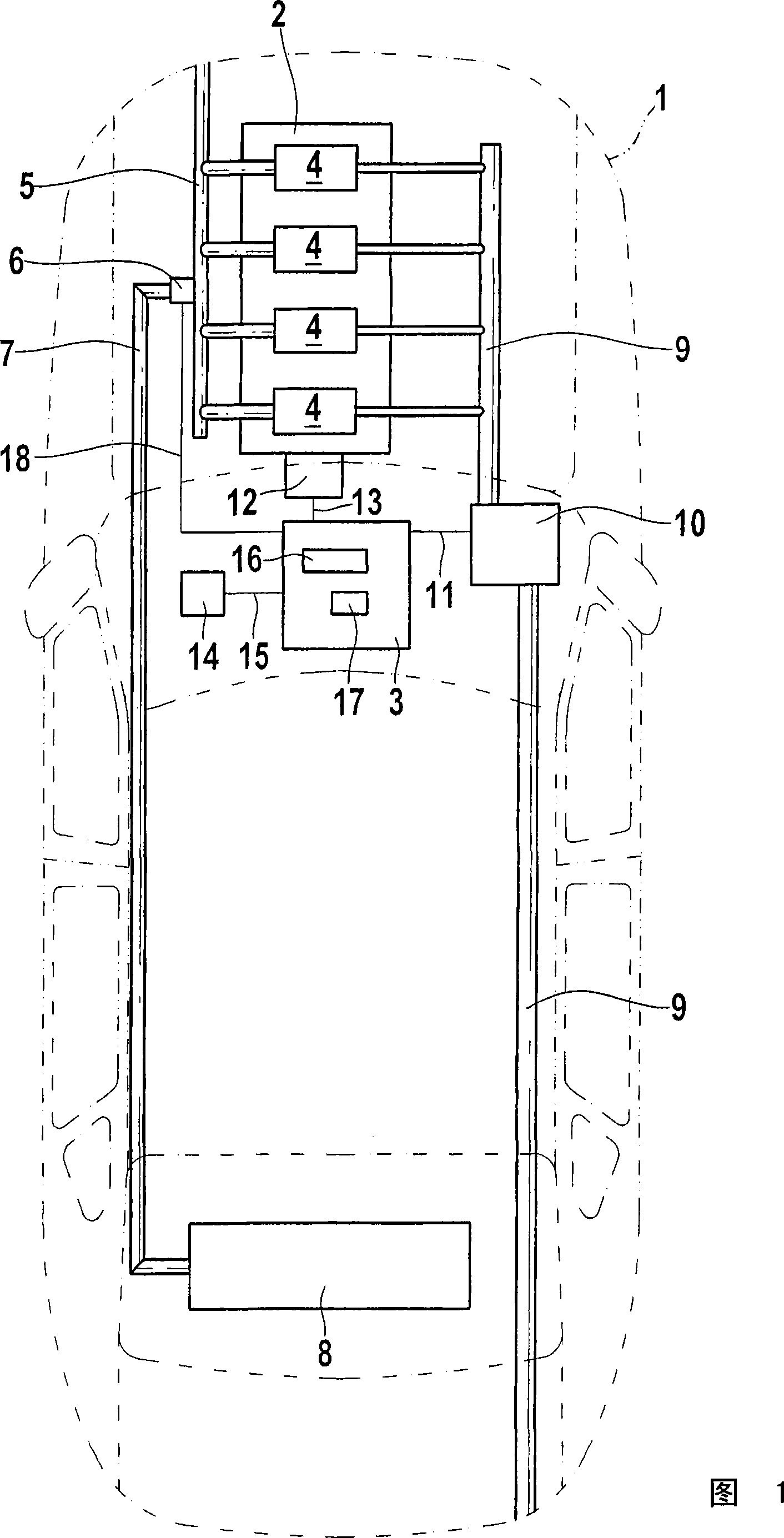

[0030] FIG. 1 schematically shows a motor vehicle 1 with an internal combustion engine 2 and a control unit 3 . The internal combustion engine 2 has cylinders 4 which are connected to an intake manifold 5 and an exhaust system 9 . Arranged in the intake line 5 is a fuel injection valve 6 which is connected via a fuel line 7 to a fuel storage container 8 . Injection valve 6 is connected to control unit 3 via a signal line 18 .

[0031] The exhaust system 9 contains an exhaust gas purification device, in particular a catalyst 10 . A sensor for determining the exhaust gas quality, in particular a lambda probe (not shown in the figure), is arranged in the exhaust system 9 and is connected to the control unit 3 via a signal line 11 .

[0032] An electric motor 12 is associated with internal combustion engine 2 . In particular, the electric motor 12 can also be part of a hybrid drive. The electric motor 12 is connected to the control unit 3 via a signal line 13 .

[0033] Motor v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com