Ester soluble dual-component polyamine ester boiling-resistant plastic-aluminum composite binder and method of manufacture

A manufacturing method and technology of aluminum-plastic compounding, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as poor high temperature resistance and inability to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

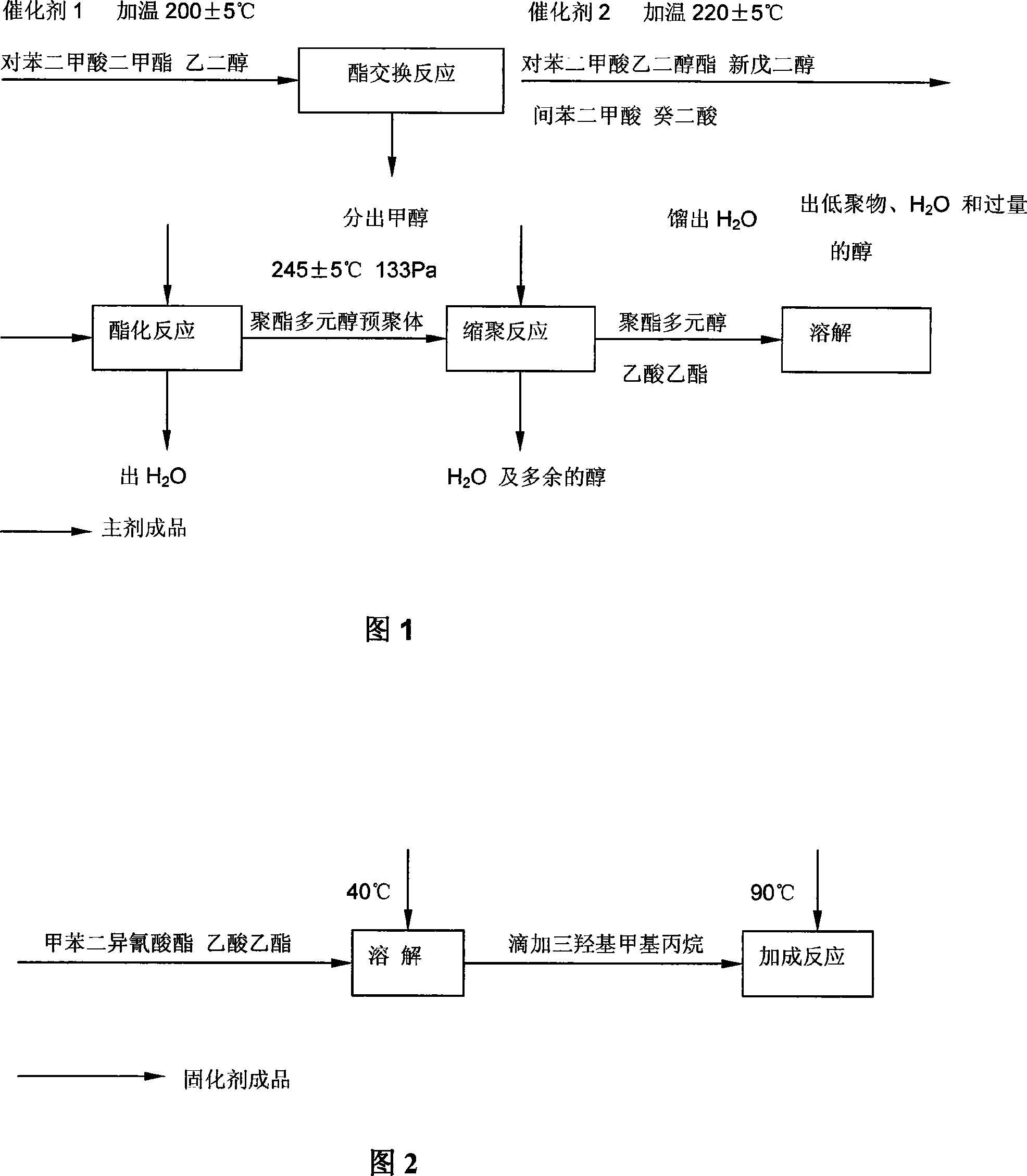

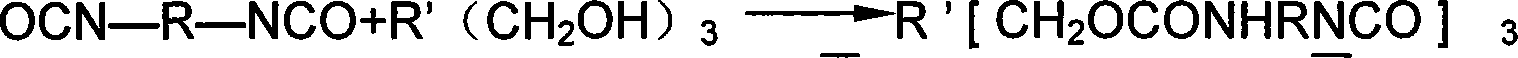

Method used

Image

Examples

example 1

[0029] (1) Main ingredient production

[0030] Calculated according to the weight percentage of the main agent: take

[0031] Ethylene glycol 12% is 48.6Kg

[0032] Dimethyl terephthalate 11% is 46.8Kg

[0033] Neopentyl Glycol 13% is 52.3Kg

[0034] 10% isophthalic acid is 41.6Kg

[0035] Sebacic acid 12.5% is 50.6Kg

[0036] Ethyl acetate 41.5% is 164Kg

[0037] Its operation steps are:

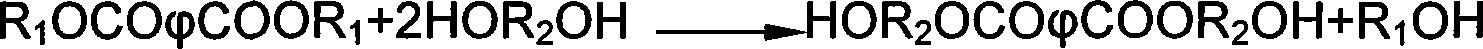

[0038] 1. Mixing: Mix 48.6Kg of ethylene glycol and dimethyl terephthalate and heat it to 200°C±10°C for 2 hours under the action of a catalyst to produce 7Kg of methanol and ethylene terephthalate. The reaction formula is:

[0039]

[0040] Cool down to 120°C, then add 52.3Kg of neopentyl glycol, 41.6Kg of isophthalic acid, and 50.6Kg of sebacic acid and heat to 220°C±10°C for 8 hours under the action of a catalyst. Its general reaction formula is:

[0041] HOCOR 3 COOH+HOR 2 OH→HOCOR 3 COOR 2 OH+H 2 o

[0042] 2. Polycondensation: Continue to heat the previous process ...

example 2

[0056] Main agent production:

[0057] Calculated according to the weight percentage of the main agent, take

[0058] Ethylene glycol 13% 39Kg

[0059] Dimethyl terephthalate 10% 30Kg

[0060] Neopentyl Glycol 13% 39Kg

[0061] Isophthalic acid 9% 27Kg

[0062] Sebacic acid 14% 42Kg

[0063] Ethyl acetate 41% 121Kg

[0064] Its operation steps are:

[0065] mix:

[0066]1. Mix 39Kg ethylene glycol and 30Kg dimethyl terephthalate and heat it to 200°C for 2 hours under the action of a catalyst to produce 5.6Kg methanol and ethylene terephthalate. The reaction formula is:

[0067]

[0068] Cool down to 120°C, then add 39Kg of neopentyl glycol, 27Kg of isophthalic acid, and 42Kg of sebacic acid and heat to 220°C for 8 hours under the action of a catalyst. Its general reaction formula is:

[0069] HOCOR 3 COOH+HOR 2 OH→HOCOR 3 COOR 2 OH+H 2 o

[0070] 2. Polycondensation: Continue to heat the previous process to 245°C, and at the same time reduce the pressure to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com