Automatic belt cutter

A tape cutting machine and automatic technology, applied in the field of machinery, can solve the problems of complex overall structure, rupture and low degree of automation, and achieve the effect of simple overall structure, high degree of automation and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

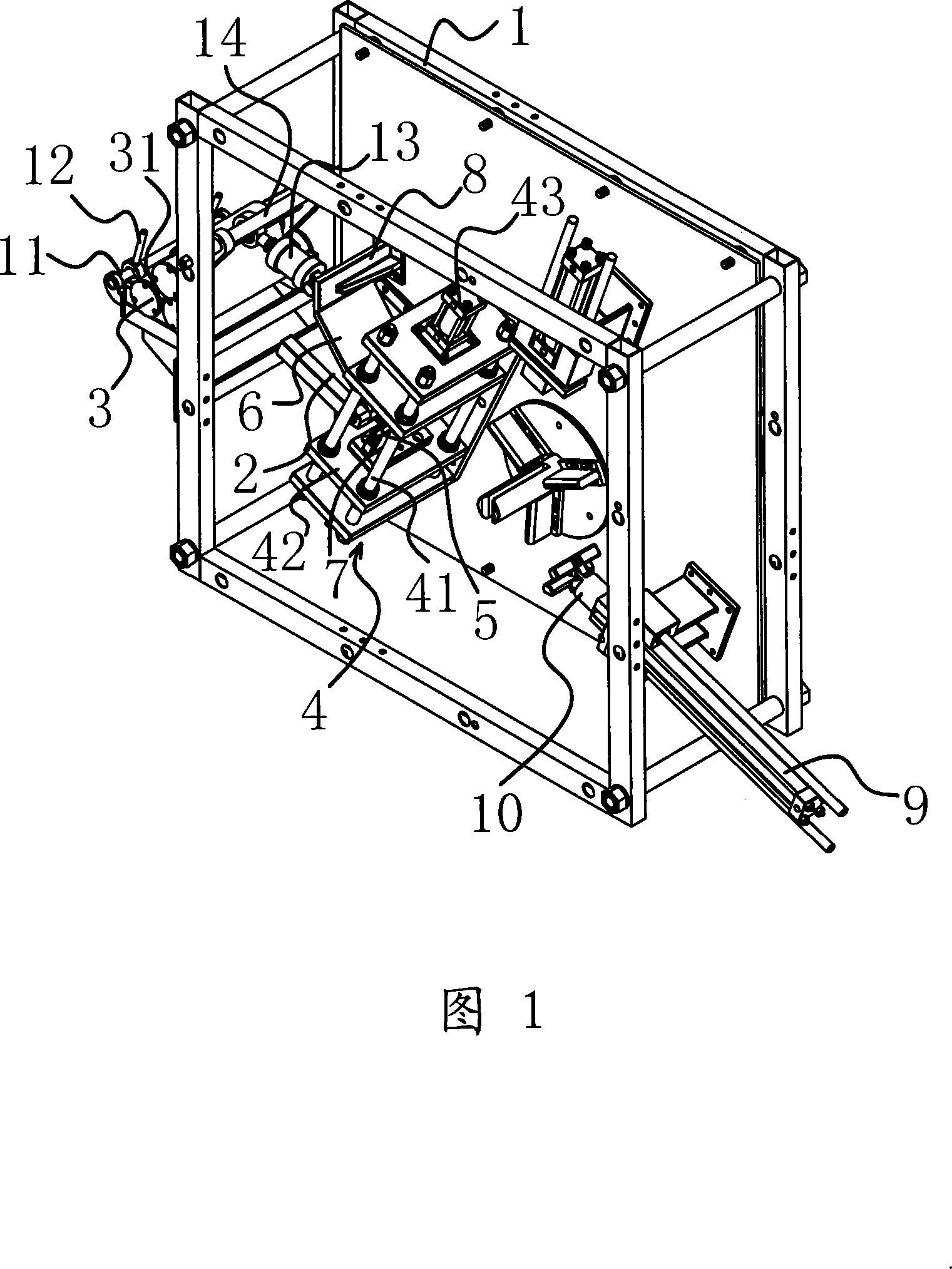

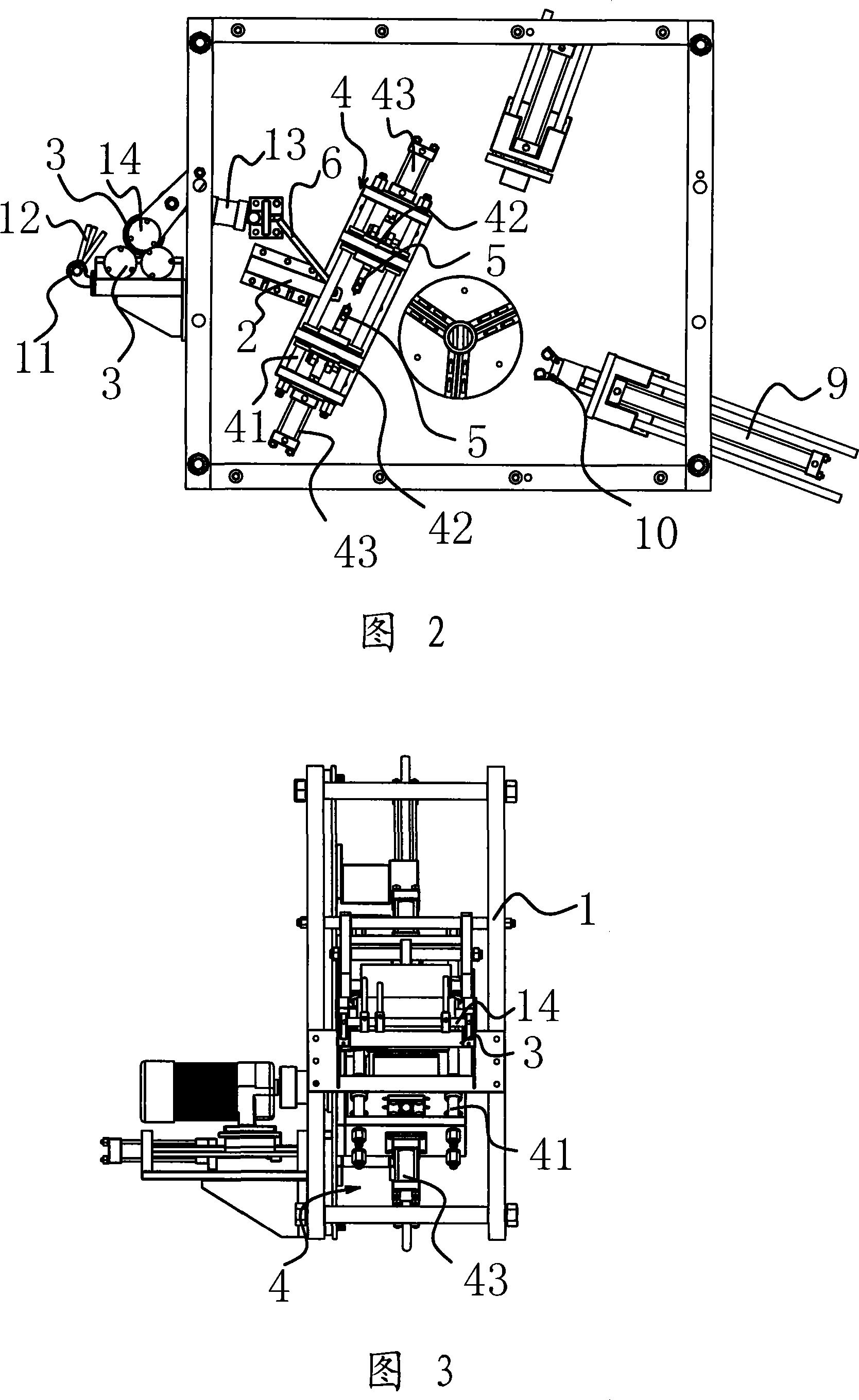

[0022] As shown in Figure 1 and Figure 2, the automatic tape cutting machine is composed of frame 1, worktable 2, roller 3, knife holder 4, cutter 5, cutting mechanism, grasping mechanism and other parts.

[0023] The workbench 2 is set on the frame 1. On one side of the workbench 2, there are three rollers 3 mounted on the frame 1 and arranged parallel to each other, and the three rollers 3 are arranged in a pin shape, and the belt can be removed from the roller 3. The gap 31 between them passes through. A grabbing mechanism for grabbing the end of the belt is provided on the other side of the workbench 2, and a cutting mechanism for cutting the belt is provided between the roller 3 and the grabbing mechanism.

[0024] During operation, the belt passes through the gap 31 between the rollers 3, and the gripping mechanism can grasp the belt and stretch it. When it is necessary to cut off, the cut-off mechanism works. The present invention can also work with the winding mechanism to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com