Pretreatment apparatus for window glass adhesive application and method of the pretreatment

A technology for adhesives and window glass, which is applied to devices for coating liquid on surfaces, windshields, and pre-treated surfaces, etc. It can solve problems such as complicated operations, inability to realize automation, and large installation space for pre-treatment processes. Achieve the effect of reducing man-hours and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

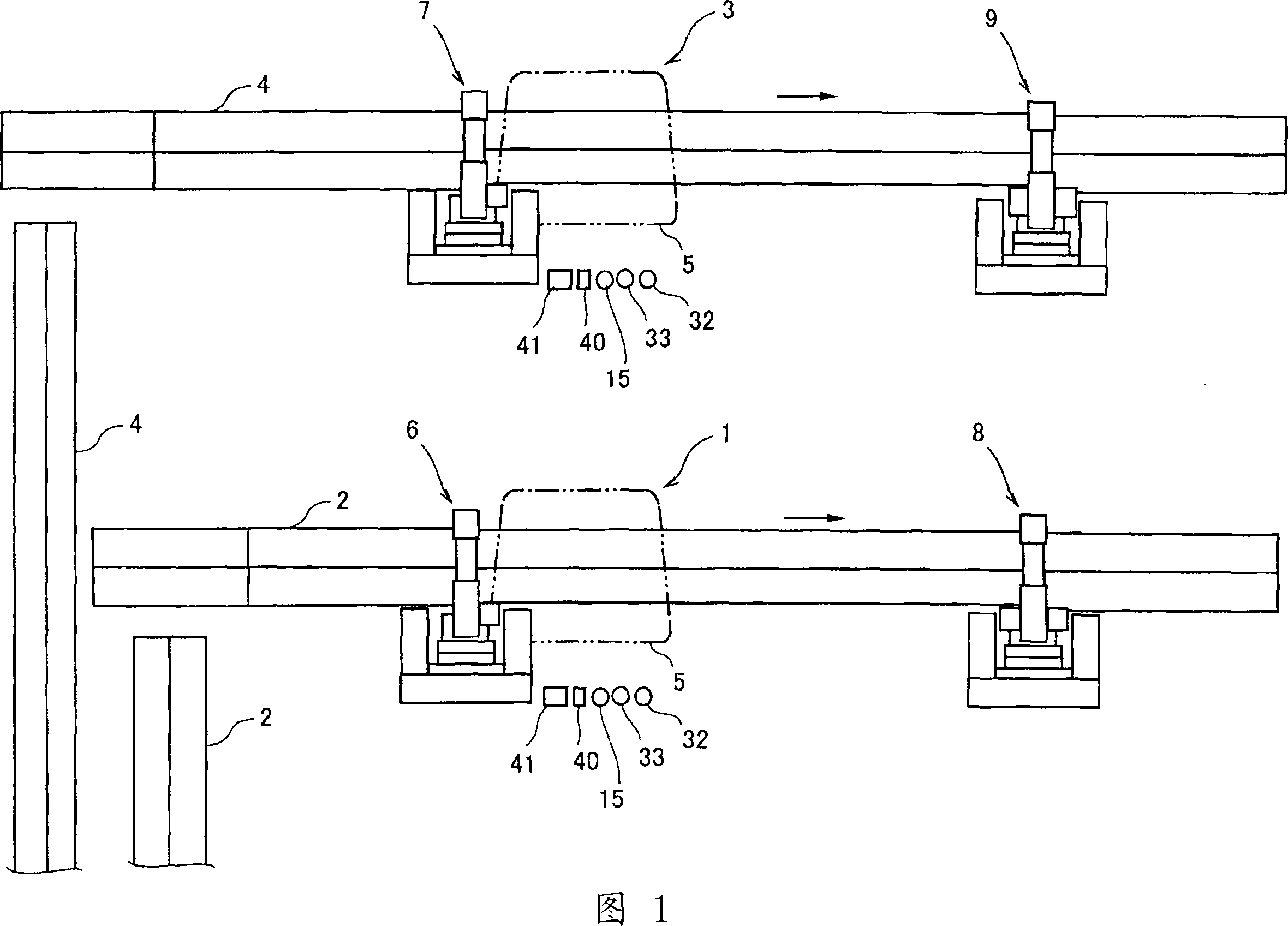

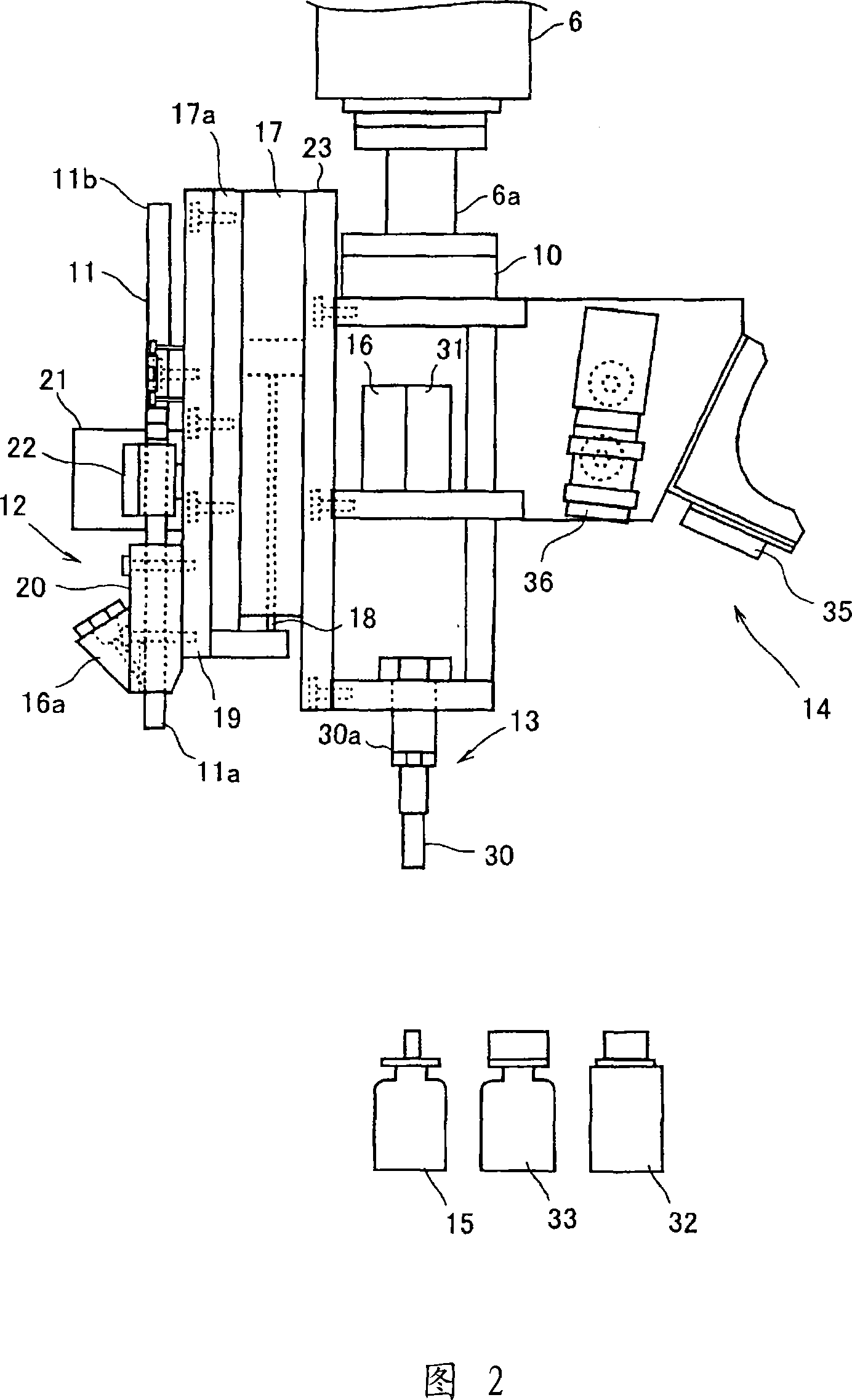

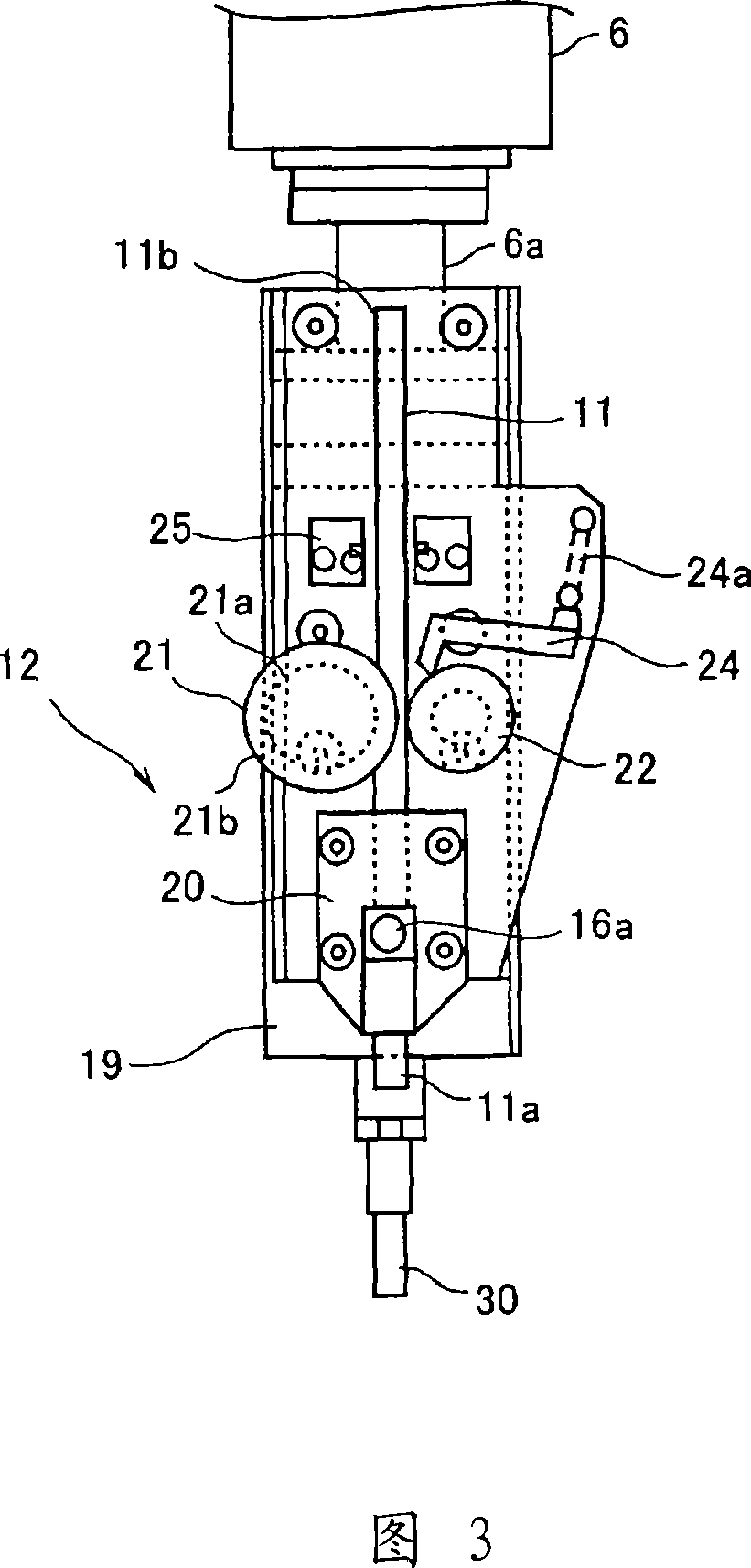

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. Here, FIG. 1 is an engineering explanatory drawing of a pretreatment device and a method thereof for applying the window glass adhesive coating of the present invention, and FIG. 2 is a front view of the pretreatment device coating of the window glass adhesive coating of the present invention, Fig. 3 is a side view thereof, Fig. 4 is a side view of a felt clamping mechanism and a cutting mechanism, Fig. 5 is a sectional view of A-A of Fig. 4 , Fig. 6 is a top view of a partial section of a felt clamping mechanism and a cutting mechanism, and Fig. 7 is Front view (a) and side view (b) of another embodiment of the primer agent inspection device, FIG. 8 is a top view of the windshield as a pre-processing object, and FIG. 9 shows the pre-processing of window glass adhesive coating As a flow chart of the operation sequence, Fig. 10 is a side view of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com