Manufacturing technique of cold-bending steel sheet pile

A production process and steel sheet pile technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of inability to limit the lateral displacement of strip steel billets, large tensile strain at the outer edge of the lock arc, and difficulty in controlling the dimensional accuracy of the lock and other problems, to achieve the effect of reducing tensile strain, reducing production cost, and reducing cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

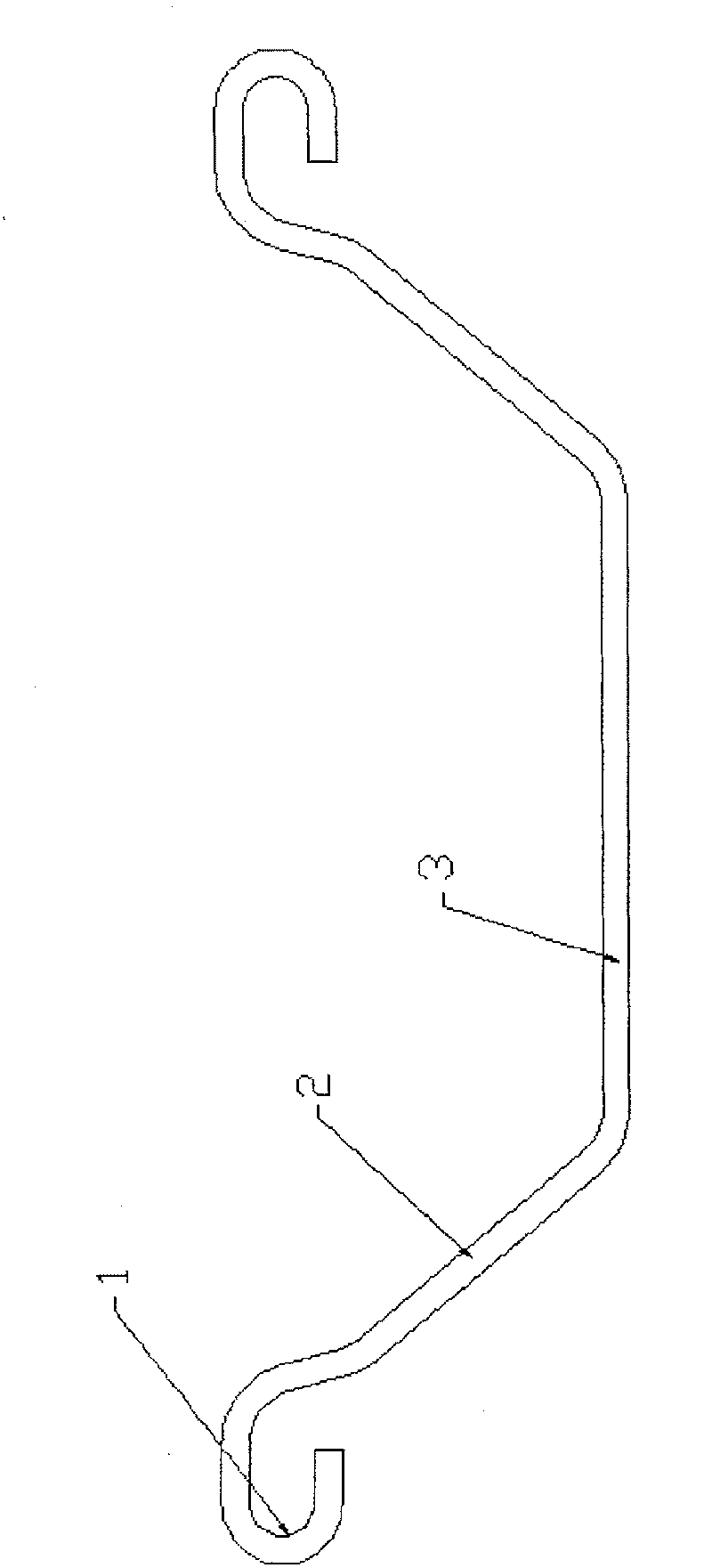

[0040] Figure 2 to Figure 10 It is a schematic diagram of the bending of each pass of the forming cold-formed steel sheet pile lock 1. Among them, strip billets 4 from image 3 (Pass 2) Start to bend, the bending angle of each pass is 22.5°, and it is divided into 8 passes to finally form the lock 1. Figure 3 ~ Figure 5 The bending of the strip steel blank 4 shown in each pass is the existing open pass, and the purpose is to bend the steel blank 4 to 90°; Image 6 It is the bending schematic diagram when the steel strip blank 4 is bent to 90°. At this moment, the closed pass type is used to bend the steel strip blank 4, Figure 6 ~ Figure 10 The bending of the strip steel billet 4 shown in each pass adopts a closed pass type for final bending to form the lock 1 of the cold-formed steel sheet pile.

[0041] Among them, when the steel strip 4 is bent at 0°-90°, the open pass of each pass is composed of a plurality of relatively rotating forming rolls: image 3 , Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com