Image sensing part and its making method

A technology of image sensing and components, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, radiation control devices, etc., can solve problems such as hindering the passivation of dangling bonds, achieve good shading effect, and improve the effect of dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

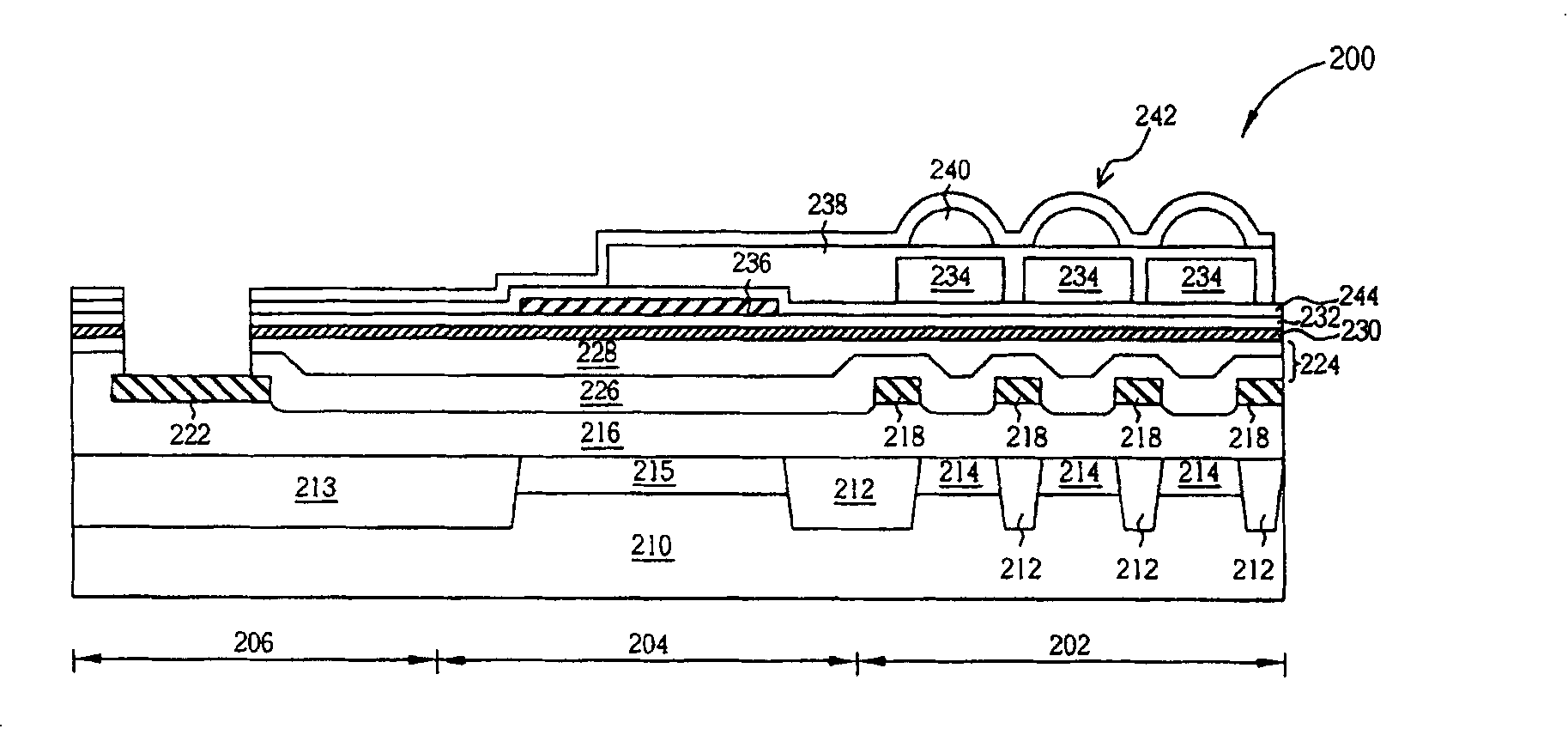

[0045] see image 3 , image 3An image sensing element 200 according to the present invention is shown. The image sensing device 200 includes a semiconductor substrate 210 , a pixel array area 202 , a logic area 206 , and an optical black area 204 . The pixel array area 202 is located on the semiconductor substrate 210 and includes a photo-sensing unit array 214 . The logic area 206 is located on the semiconductor substrate 210 and includes peripheral circuits. The optical black area 204 is located between the pixel array area 202 and the logic area 206 on the semiconductor substrate, including a photo-sensing unit 215 located on the semiconductor substrate 210, a first planarization layer 216 located on the photo-sensing unit 215, a The second planarization layer 224 is located on the first planarization layer 216 , and an optical black layer 236 is located on the second planarization layer 224 .

[0046] It should be noted that the optical black layer 236 includes a meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com