Special high temperature-resistant electrical cable and its production method

A power cable and high-temperature-resistant technology, which is applied in the field of special high-temperature-resistant power cables and their manufacturing, can solve the problems of difficult peeling, cable heating and burning, and rapid heating of cables, so as to increase the feel and aesthetics and reduce the external environment. Interference, the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

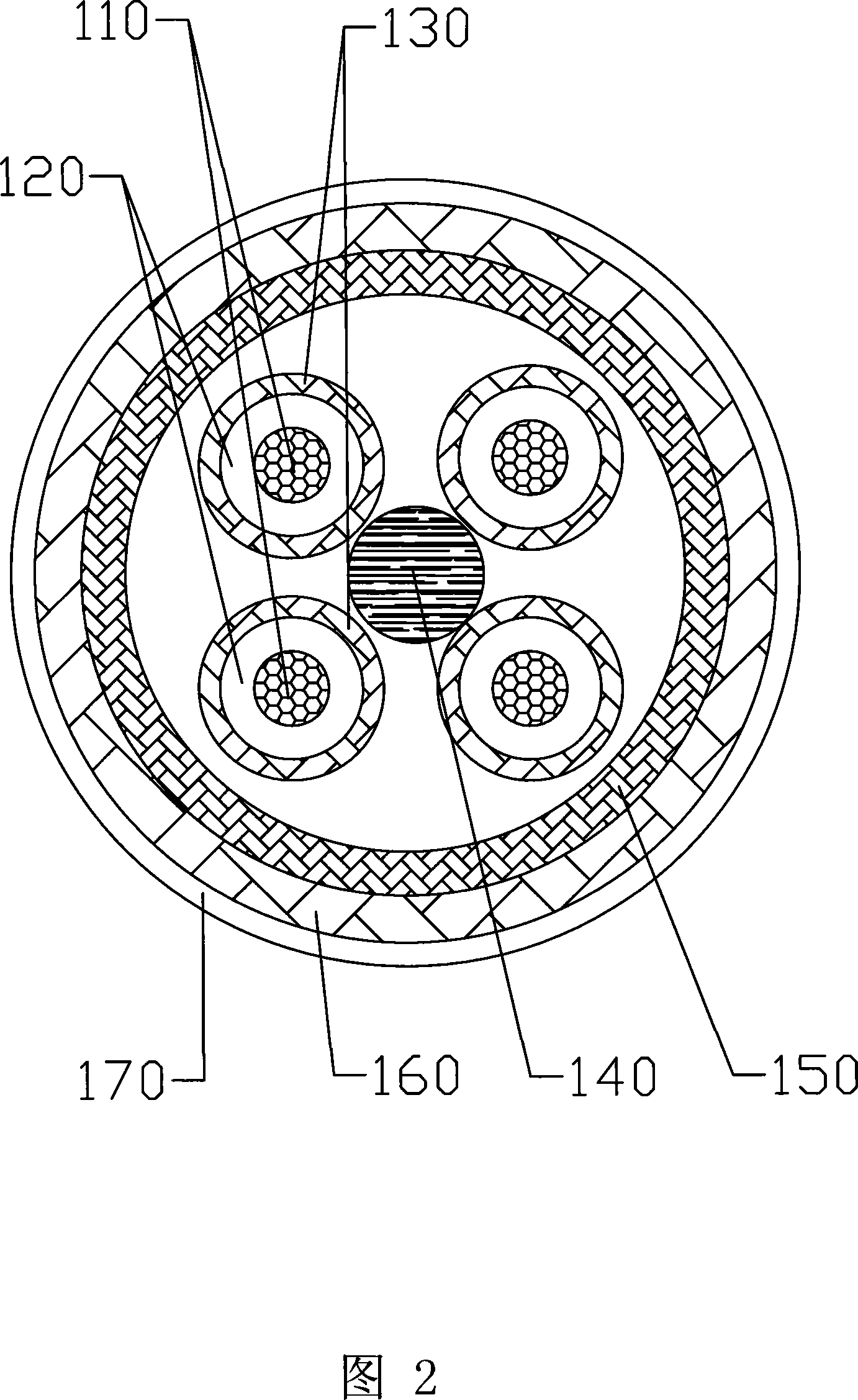

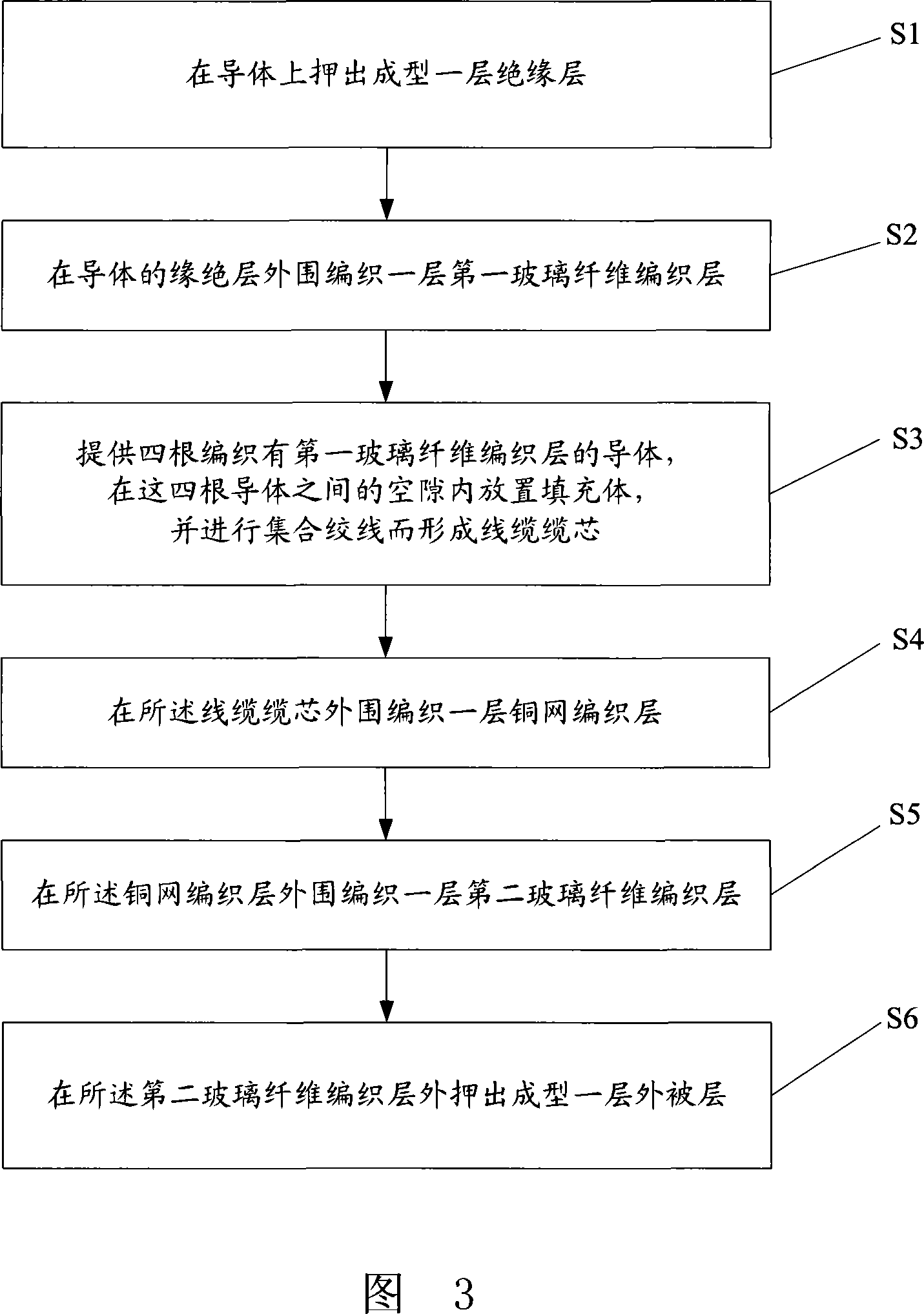

[0023] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As described above, the present invention provides a power cable. The power cables are all made of high temperature resistant materials, which can ensure the safe operation of power signals. In addition, the glass fiber braiding layer makes it easy to peel off the access end of the power cable when it is connected to other lines. In addition, the gaps between several conductors of the present invention are filled with fillers, which can ensure better roundness of the power cable of the present invention, and increase its hand feeling and aesthetic feeling.

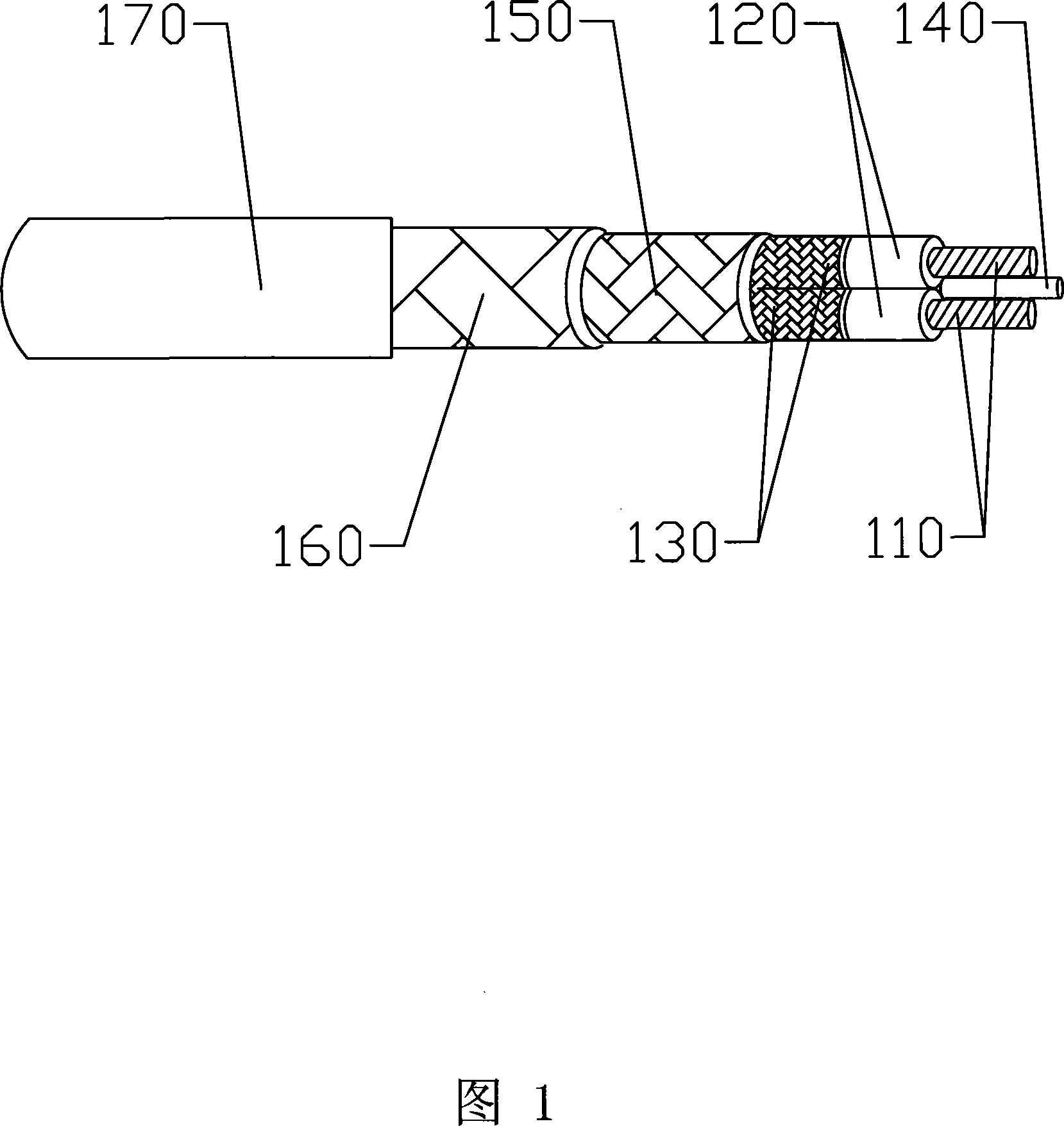

[0024] Figures 1-2 show an embodiment of the power cable of the present invention. As shown in the figure, the power cable provided by the present invention includes four conductors 110, an insulating layer 120, a first glass fiber braided layer 130, a filler 140, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com