Cone-beam CT system plate detector image anti-interference calibration method

A flat-panel detector, correction method technology, applied in image enhancement, image data processing, image data processing and other directions, can solve the problem of not completely effective removal of artifacts, etc., to achieve the effect of removing linear and ring artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

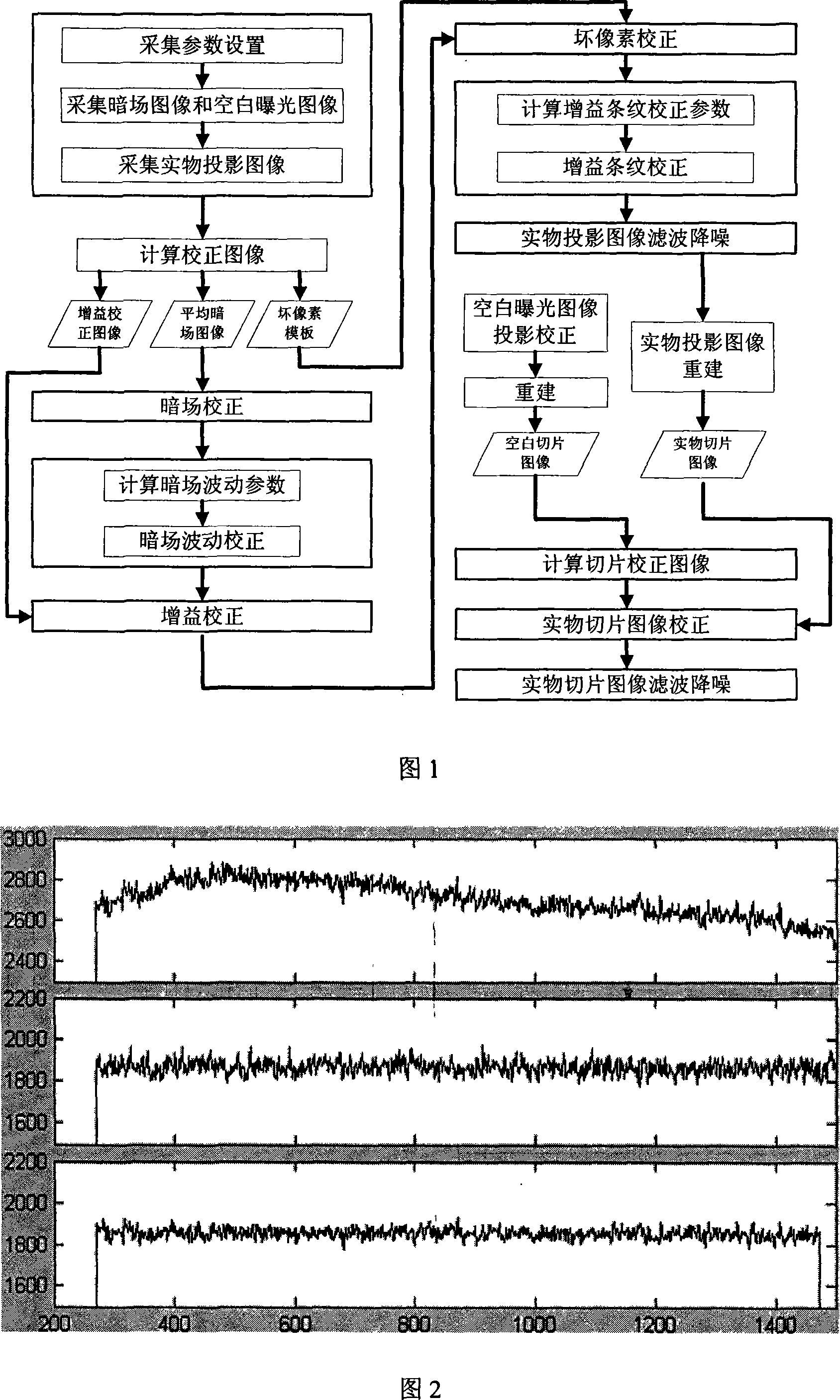

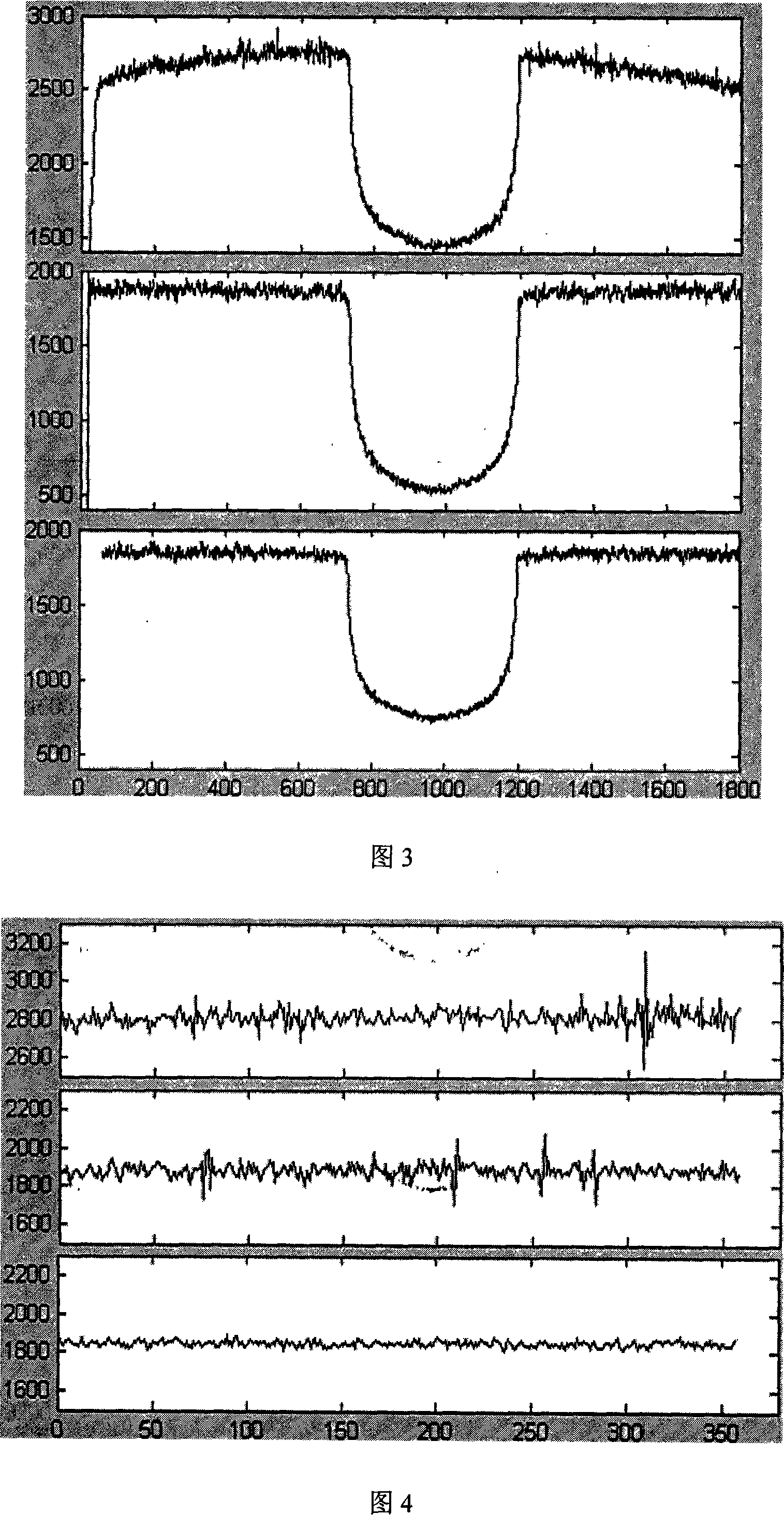

[0043] As shown in Figure 1, this example selects a cylindrical aluminum part to verify the correction effect, and the operation process is as follows:

[0044] 1. Parameter adjustment and data collection can be subdivided into the following three main steps:

[0045] (1) Adjust the acquisition parameters (such as ray source voltage, current, flat panel detector exposure time, etc.) according to the measured object, so that the output of the flat panel detector can be kept in a region with better linearity. Install a rectangular shielding plate (the direction of the long side of the rectangle is the column direction) so that it shields the pixel output of 100 columns.

[0046] (2) Under the acquisition parameters, a certain number of dark field images and blank exposure images are collected. The number of dark field images depends on the stability of the dark field. The worse the stability, the greater the number of images collected. In this example, 360 dark field images are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com