Method for preparing battery-stage anhydrous lithium chloride

A battery-grade lithium chloride technology, applied in the direction of alkali metal chloride, etc., can solve problems such as waste of energy, high content of barium chloride, and increased evaporation in the process, so as to reduce the loss of lithium, shorten the process route, and improve the operation efficiency. The effect of step simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

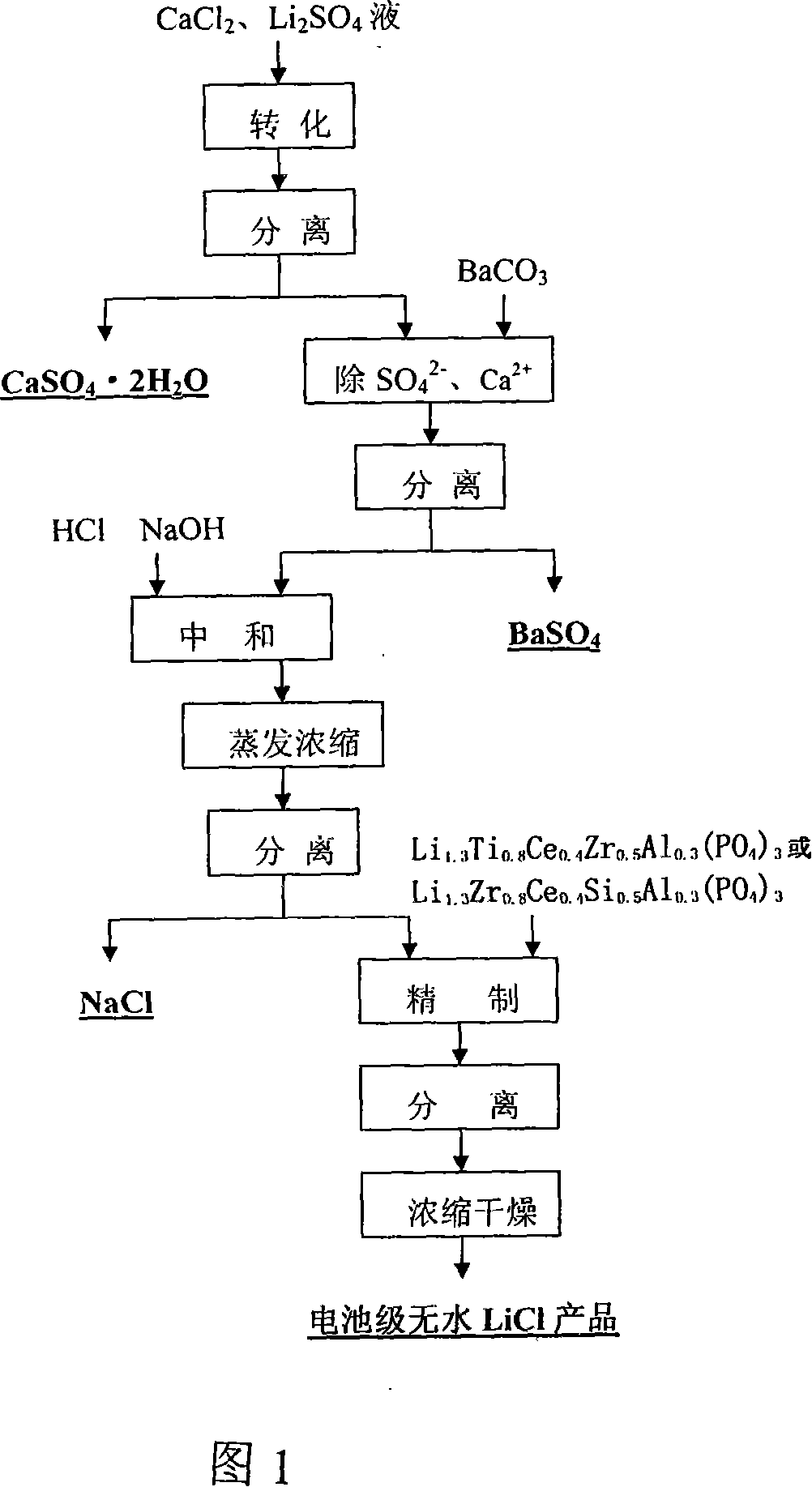

[0063] Referring to Fig. 1, the preparation method of battery-grade anhydrous lithium chloride of embodiment 1 of the present invention comprises the following steps:

[0064] (1) Will Li 2 Li with an O concentration of 25 g / l 2 SO 4 Solution - Add 6000ml of lithium concentrate acid clinker leaching solution into a stainless steel reaction vessel, and add 659g of CaCl under stirring 2 80% CaCl 2 2H 2 Add NaOH to adjust the pH value to 11.5, and react at 90°C for 50 minutes. After keeping the temperature for 80 minutes, vacuum filter and wash the filter cake with deionized water. The washing water is used for the next preparation of CaCl 2 Solution, filter cake as by-product CaSO 4 2H 2 0, the filtrate is LiCl solution (conversion solution);

[0065] (2) Adding 102g of BaCO with a main content of 99% in the conversion liquid obtained in step (1) 3 , after stirring and reacting for 120min, vacuum filtration, the filter cake was washed with deionized water, and the filter...

Embodiment 2

[0072] Referring to Fig. 1, the preparation method of battery-grade anhydrous lithium chloride of embodiment 2 of the present invention comprises the following steps:

[0073] (1) Will Li 2 Li with an O concentration of 25 g / l 2 SO 4 Solution - Add 6000ml of lithium concentrate acid clinker leaching solution into a stainless steel reaction vessel, add 555g of CaCl under stirring 2 80% CaCl 2 2H 2 Add NaOH to adjust the pH value to 9, and react at 65°C for 30 minutes. After keeping the temperature for 60 minutes, vacuum filter, wash the filter cake with deionized water, and use the washing water for the next preparation of CaCl 2 Solution, filter cake as by-product CaSO 4 2H 2 0, the filtrate is LiCl solution (conversion solution);

[0074] (2) Adding 118g of BaCO with a main content of 99% in the conversion liquid obtained in step (1) 3 , after stirring and reacting for 80min, vacuum filtration, the filter cake was washed with deionized water, and the filter cake was t...

Embodiment 3

[0080] Referring to Fig. 1, the preparation method of battery-grade anhydrous lithium chloride of embodiment 3 of the present invention comprises the following steps:

[0081] (1) Will Li 2 Li with an O concentration of 25 g / l 2 SO 4 Solution - Add 6000ml of lithium concentrate acid clinker leaching solution into a stainless steel reaction vessel, and add 590g of CaCl under stirring 2 80% CaCl 2 2H 2 Add NaOH to adjust the pH value to 10, and react at 80°C for 50 minutes. After keeping the temperature for 70 minutes, vacuum filter and wash the filter cake with deionized water. The washing water is used for the next preparation of CaCl 2 Solution, filter cake as by-product CaSO 4 2H 2 0, the filtrate is LiCl solution (conversion solution);

[0082] (2) Adding 109g of BaCO with a main content of 99% in the conversion liquid obtained in step (1) 3 , after stirring and reacting for 100min, vacuum filtration, the filter cake was washed with deionized water, and the filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com