Technique for preparing ammonia from urea by pyrolysis method

A pyrolysis and urea technology, applied in the field of flue gas denitrification, can solve the problems of less common use, high cost and large water consumption, and achieve the effects of simple operation, fast response time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

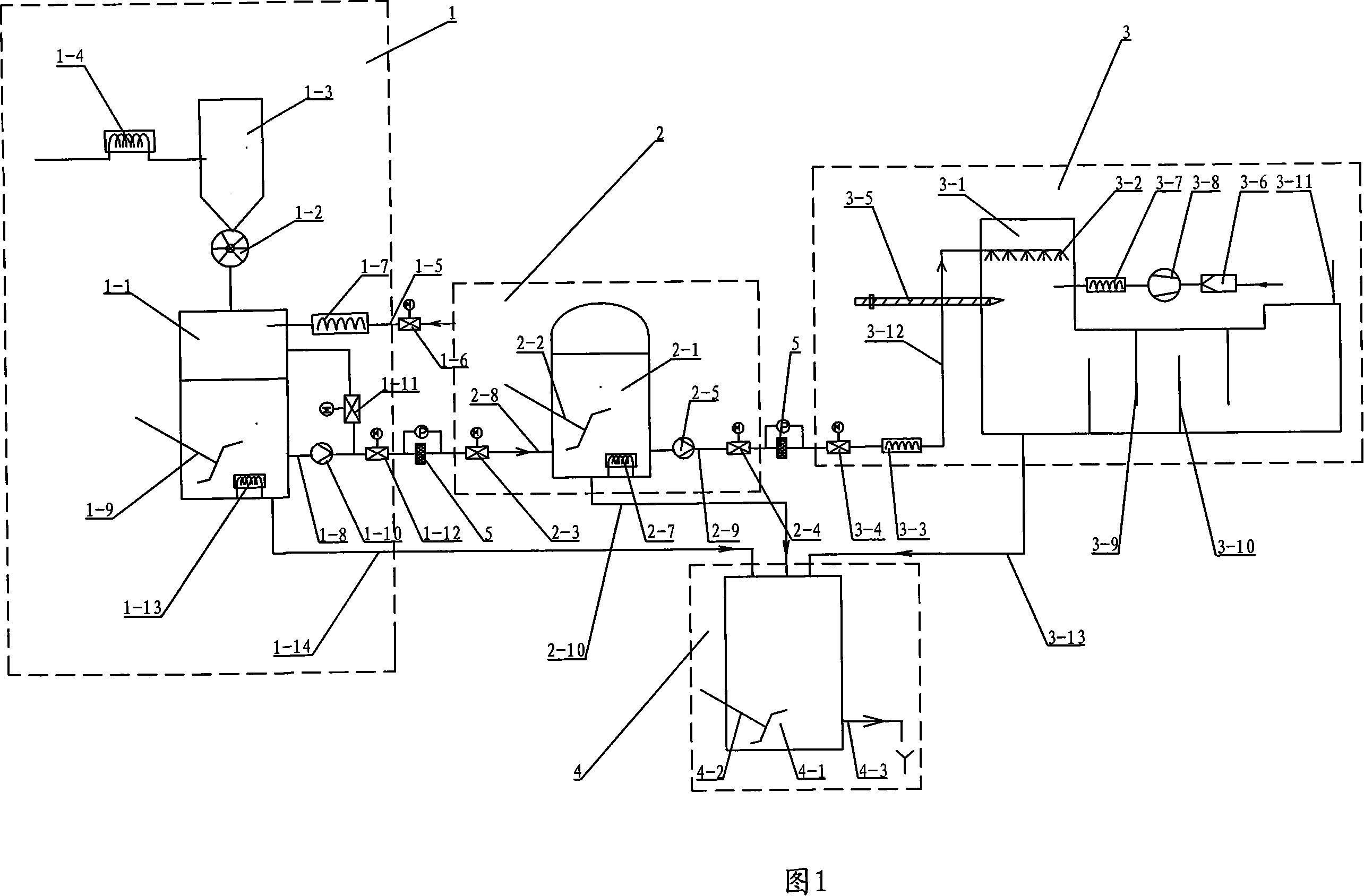

[0040] Please refer to Figure 1, taking the urea ammonia production system with an ammonia output of 14.2Kg / h as an example for illustration:

[0041] 1. Urea granule storage and dissolution system

[0042] After the purchased urea granules are delivered by trucks, they are stored in the urea granule storage tanks 1-3, and the gasification wind electric heater 1-4 keeps the urea granules dry to prevent the urea granules from being damp and crystallized. The ammonia output is 14.2Kg / h, calculated based on continuous operation for 5 hours, the volume of the urea granule storage bin is 120L,

[0043] The urea dissolving tank 1-1 is made of stainless steel and has a volume of 200L. It flows into the desalted water through the water delivery pipe 1-6 to dissolve, and is prepared into a 40% urea solution. The water delivery pipe 1-6 is equipped with a water delivery cumulative flow meter 1-7 to ensure The concentration of the prepared urea solution is 40%, and 40Kg of urea granules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com