Environment-friendly type pig feed and production method thereof

A kind of feed and environmental protection technology, applied in the field of pig feed and its production, can solve the problems of waste of limited feed resources, reduce the competitiveness of breeding industry, ecological environment pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

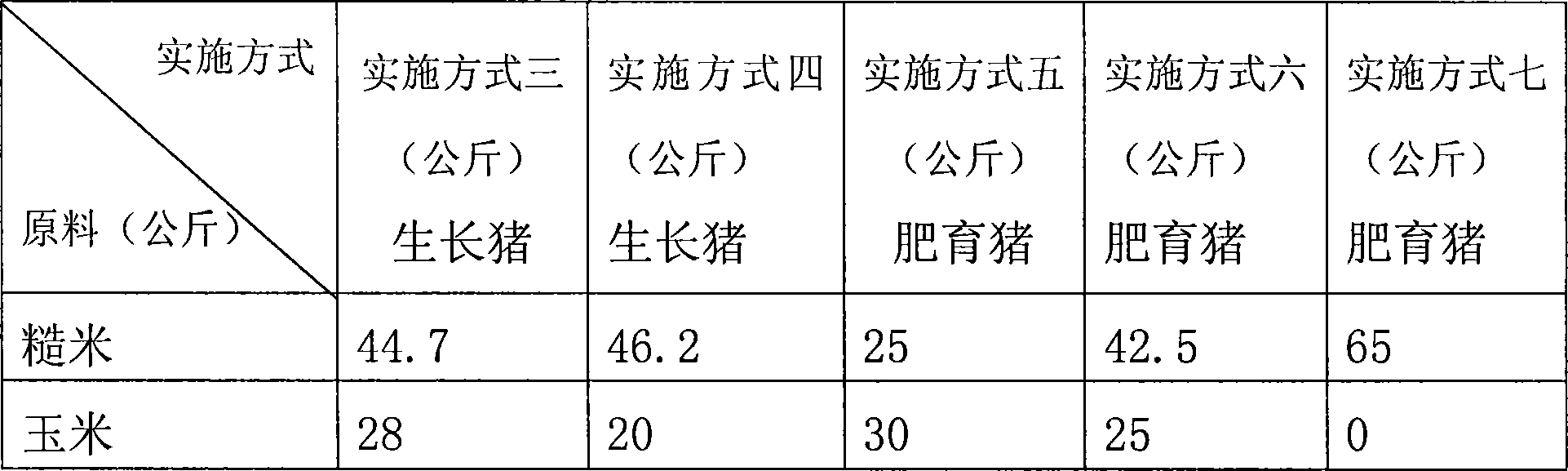

Image

Examples

Embodiment approach 1

[0023] This is the feed used in the present invention for raising 20-50 kg heavy growing pigs. To produce 100 kg of this feed (unit: kg): brown rice 50.2 corn 20.0 soybean meal 12.0 wheat bran 5.0 fish meal 4 vegetable oil 6.0 salt 0.3 calcium hydrogen phosphate 0.5 sea Paoite 1.0 Premix 1.0 (the premix is mainly composed of copper, zinc, iron, manganese, iodine, selenium, amino acids, and commercially available vitamins, and the proportion of each component to the total amount of the premix is not required. specific circumstances to adjust).

[0024] Proceed as follows during production:

[0025] a, earlier all kinds of raw materials (copper, zinc, iron, manganese, iodine, selenium, amino acid, commercially available vitamins) in the premix are pulverized, cross a 15-20 mesh sieve, and set aside;

[0026] b. Grinding 51.2 kg of brown rice, 20 kg of corn, 12 kg of soybean meal and 5 kg of wheat bran to 6-12 mesh, set aside;

[0027] c, pre-mixing the powder obtained in s...

Embodiment approach 2

[0035] This is the feed used in the present invention to raise 50-100 kg of fattening pigs. To produce 100 kg of this feed, (unit: kg): brown rice 37.2 corn 30.0 meal 20.0 wheat bran 5.0 vegetable oil 5.0 salt 0.3 calcium hydrogen phosphate 0.5 sepiolite 1.0 Premix 1.0

[0036] The production method is the same as the first embodiment.

[0037] The following is the feeding experiment and metabolism experiment done by the inventor with the feed of the present embodiment, and the results are shown in Table 2, which reflects the feed of the present embodiment on the nitrogen balance and production performance of fattening pigs.

[0038] Table II:

[0039] Test indicators

control group

this invention

Dry matter intake kg / d

Fecal dry matter output g / d

Nitrogen intake g / d

Fecal nitrogen g / d

Urine nitrogen g / d

Total nitrogen discharge g / d

Nitrogen absorption g / d

Deposited nitrogen g / d

Depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com