Method and apparatus for growing a group (III) metal nitride film and a group (III) metal nitride film

A nitride, thin film technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of expensive heater, uneconomical heater, high cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0626] Comparative Example 1 - Exposure to growth conditions inside a growth chamber for growing gallium nitride thin films Gold film

[0627]A thin evaporated gold film was exposed to the plasma conditions used in the method described in International PCT Patent Application No. PCT / AU2003 / 000598. These conditions include: the pressure in the growth chamber is about 1 Torr, but no trimethylgallium is present. Using the same conditions as for film growth in the presence of trimethylgallium, the resulting GaN film is slightly yellowish. For the gold film, damage was observed when it was peeled from the glass substrate on which it was deposited. When the film was peeled off, the glass substrate was at room temperature. It is believed that the incident nitrogen species during remote plasma travel is still very energetic during film growth, despite the considerable distance (approximately 25 cm) between the plasma source and the substrate.

[0628] Example 2 - GaN film gro...

Embodiment 3

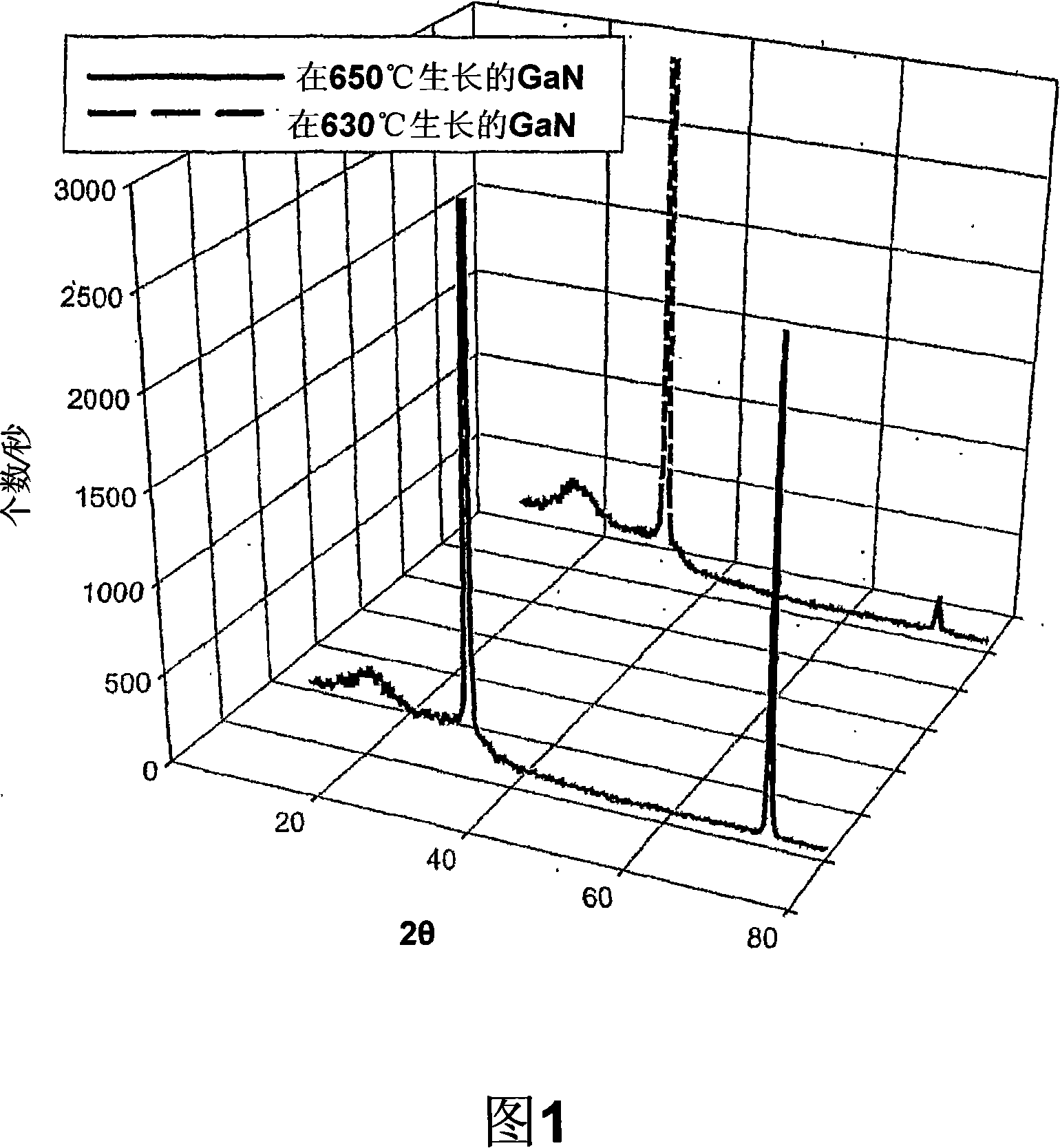

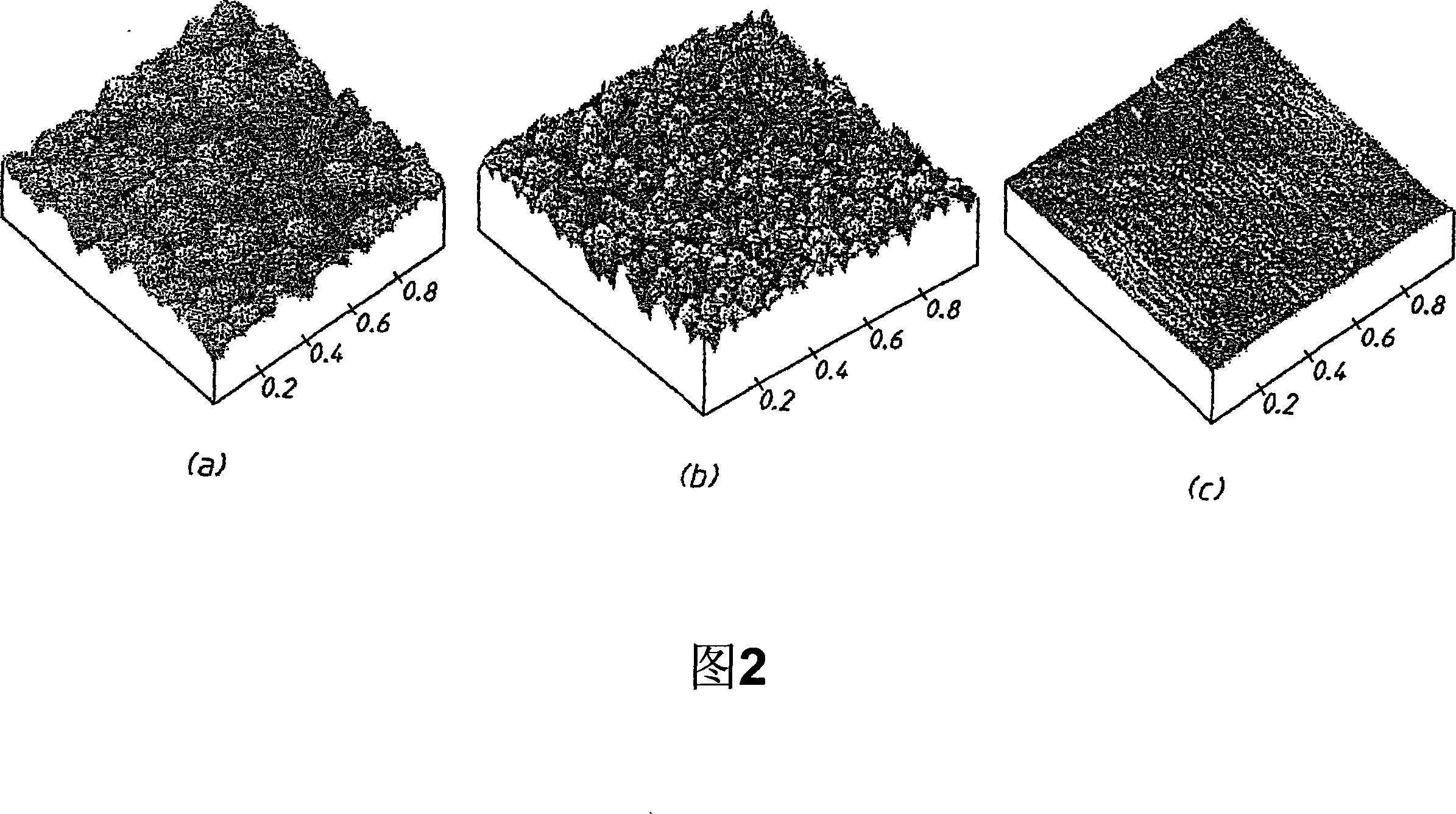

[0632] Example 3 - A series of GaN thin films grown using RPECVD at 3 Torr

[0633] The results of various GaN thin films grown using methods according to the invention in devices according to the invention are shown below and discussed. In this method, a lower base pressure (approximately 10 -7 Torr), maintaining good control over gas flow during GaN thin film growth by using pressure valves controlled by Baritron feedback from manometers. The nitrogen flow rate was approximately 600 sccm / min. Trimethylgallium was introduced as a mixture with nitrogen carrier gas at a flow rate of approximately 5 sccm / min. The ratio of trimethylgallium and nitrogen carrier is about 1:2000, and the pressure during film growth is 3 Torr.

[0634] The setup differs in its geometry from those previously used to grow GaN thin films, especially in the orientation of the introduced gas and plasma feeds. In the setup used, the incoming gas and plasma feed were directed down onto the substrate h...

Embodiment 4

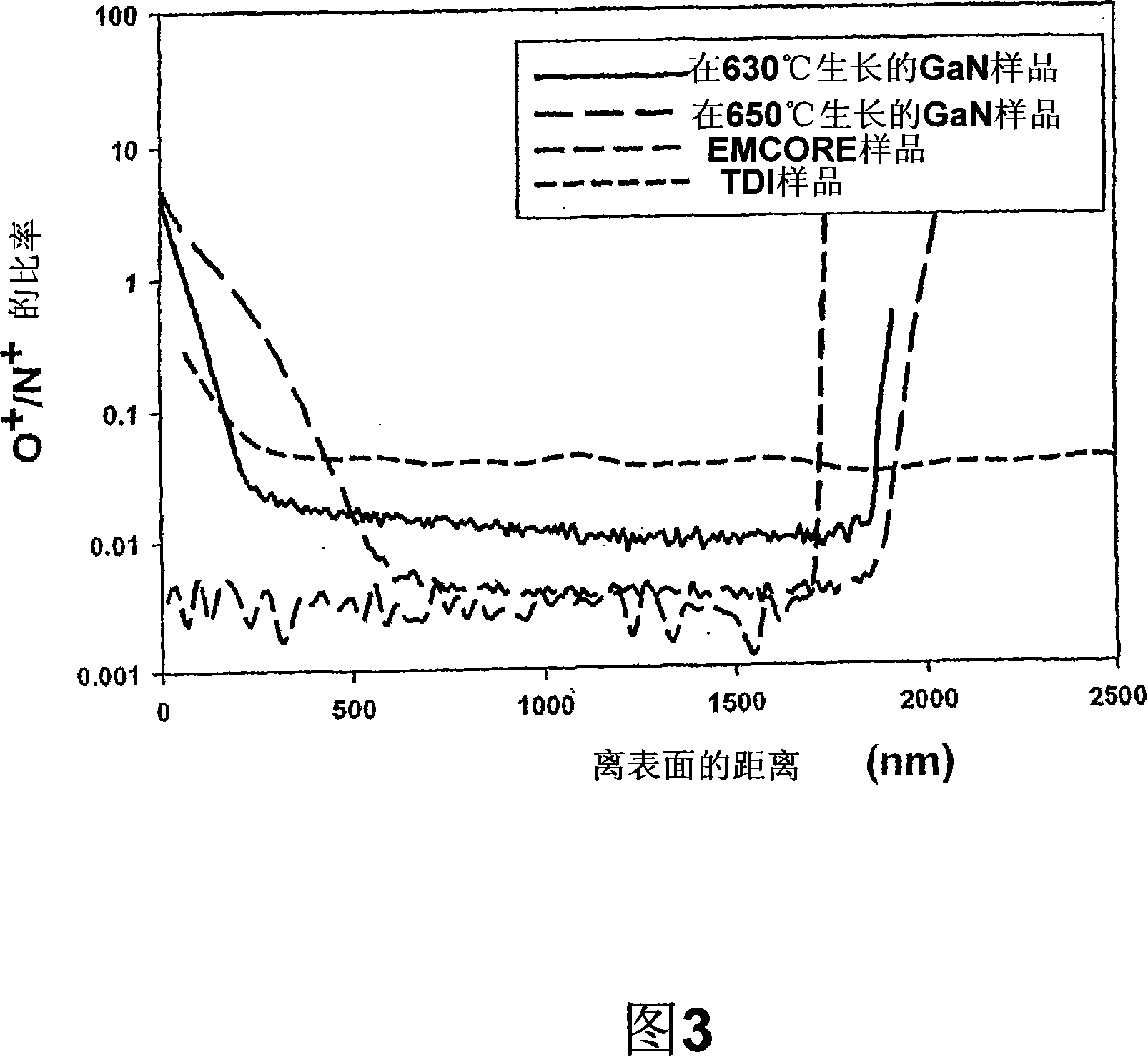

[0659] Example 4 - Comparative example of a GaN thin film grown without any passivation

[0660] Conventional RPECVD systems without pre-vacuum locks pump down to approximately 2×10 -5 to 2×10 -6 Base pressure between Torr. The growth chamber was exposed to the ambient environment (although nitrogen flow was used during sample loading in an attempt to minimize exposure of the interior surfaces of the device to atmospheric oxygen). A nitrogen purifier is used to keep impurities in the nitrogen to less than 1 part per billion.

[0661] When the system is not in use, the growth chamber is kept under vacuum to avoid contact of the interior surfaces of the device with atmospheric oxygen. The system pressure is usually maintained at the aforementioned base pressure.

[0662] For thin film growth, the substrate was introduced into the system after turning off the vacuum pump from the growth chamber and flushing with purge nitrogen. The substrate is introduced through the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com