Method for cleaning cartridge and cleaning device

A technology for cleaning devices and ink cartridges, which is applied to cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., and can solve the problems of limited cleaning capacity, insufficient cleaning, and residual ink cartridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

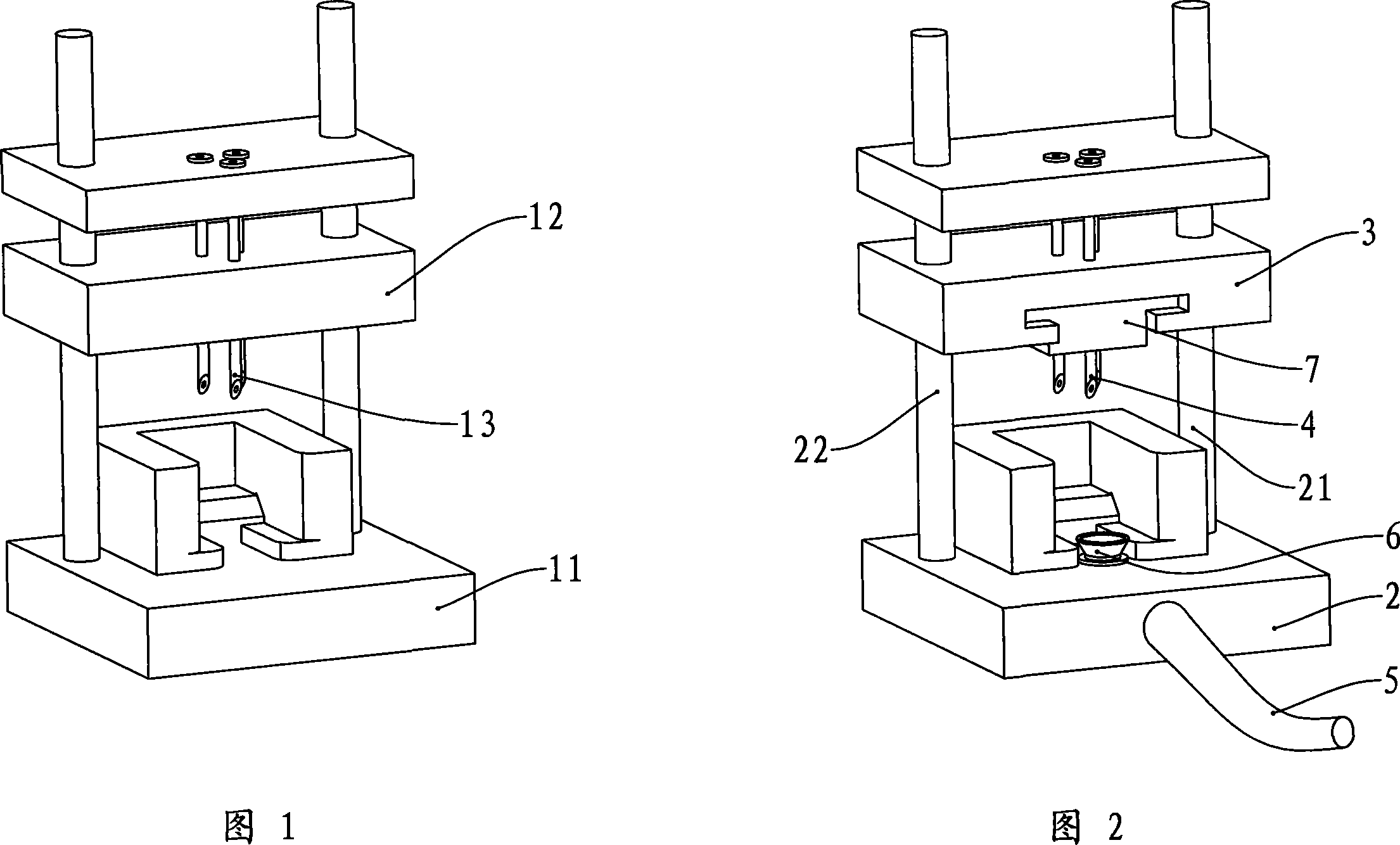

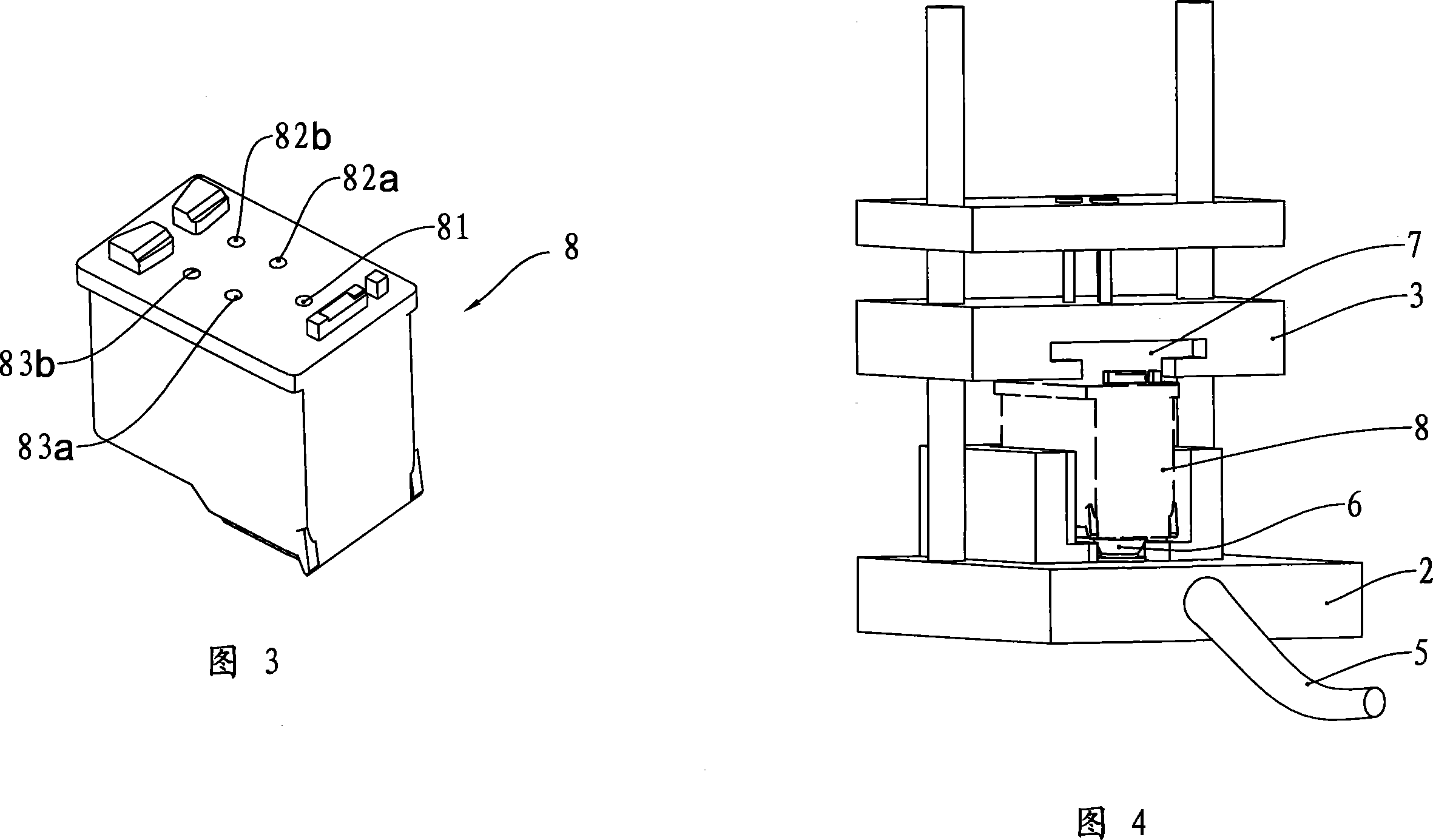

[0021] Referring to FIG. 2 , the ink cartridge cleaning device includes a base 2 , a moving base 3 , a conduit 4 , a negative pressure suction pipe 5 , a suction nozzle 6 and a seal 7 . The base 2 is generally a flat plate, which can be placed on a flat ground, a desktop or a workbench. Two uprights 21,22 are fixed on the base 2, and the movable base 3 is installed on the uprights 21,22, and the movable base 3 can move up and down relative to the base 2 by means such as hydraulic pressure or machinery. Three conduits 4 are fixed on the moving seat, and can move up and down relative to the base 2 together with the moving seat 3 . The head of conduit 4 faces base 2, is made of metal or plastics with certain hardness, can be inserted into the ventilation hole 81 (seeing figure 3) of reclaiming ink cartridge 8, conduit 4 is connected with water supply source, can inject in reclaiming ink cartridge Deionized water with a certain water pressure. Deionized water contains less calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com